Sole Structure

a technology of sole structure and recycled materials, applied in the field of sole structure, can solve the problems of defective products increasing, the proportion limit of recycled materials in the fresh rubber material, and irregular patterns and/or colors, etc., and achieve the effect of improving the sole structure, reducing the weight of the product, and improving the appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]To allow the features and applicability of the present invention to be easily understood, an embodiment with reference to the accompanying drawings will be detailed in the following paragraphs.

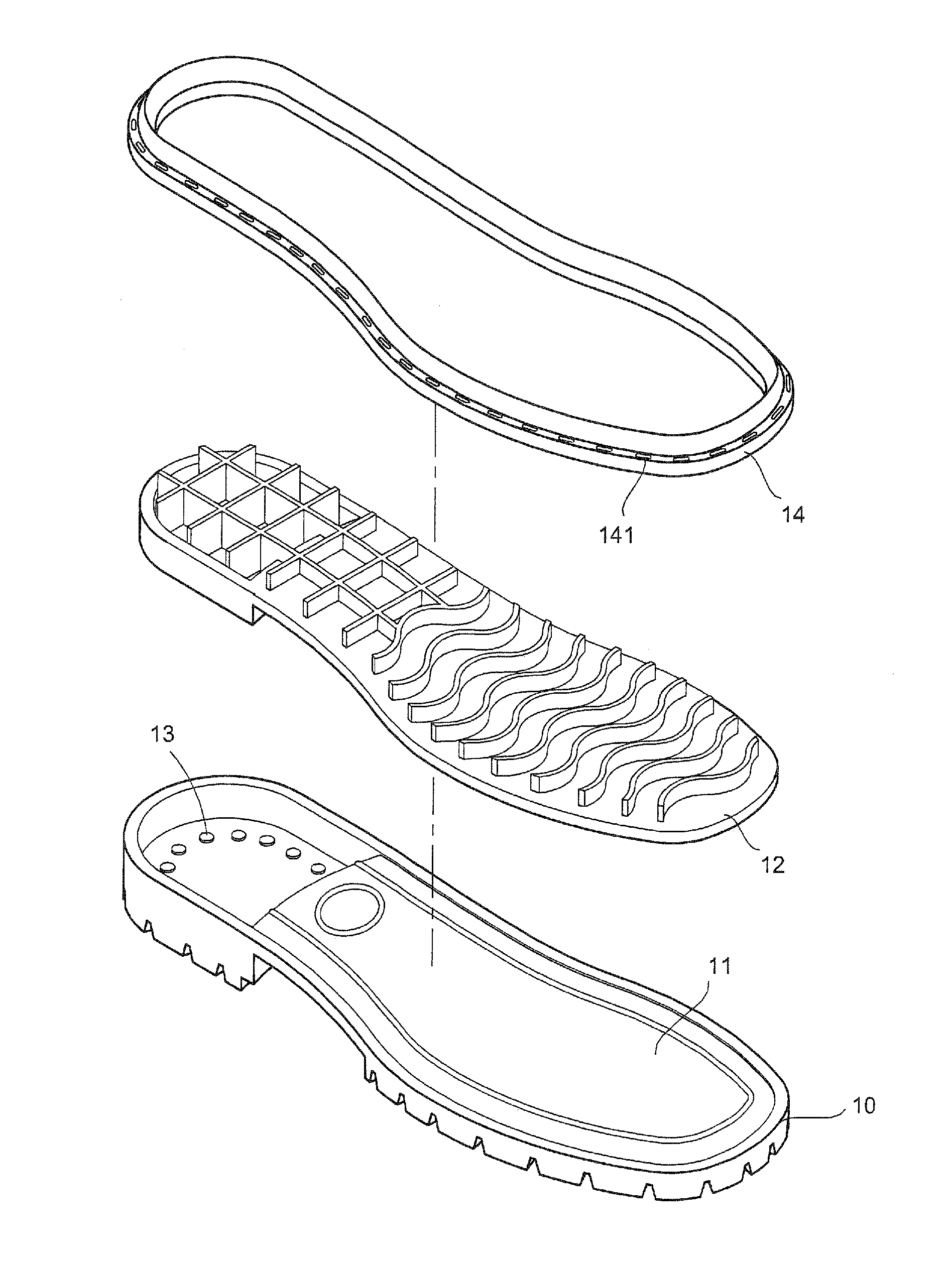

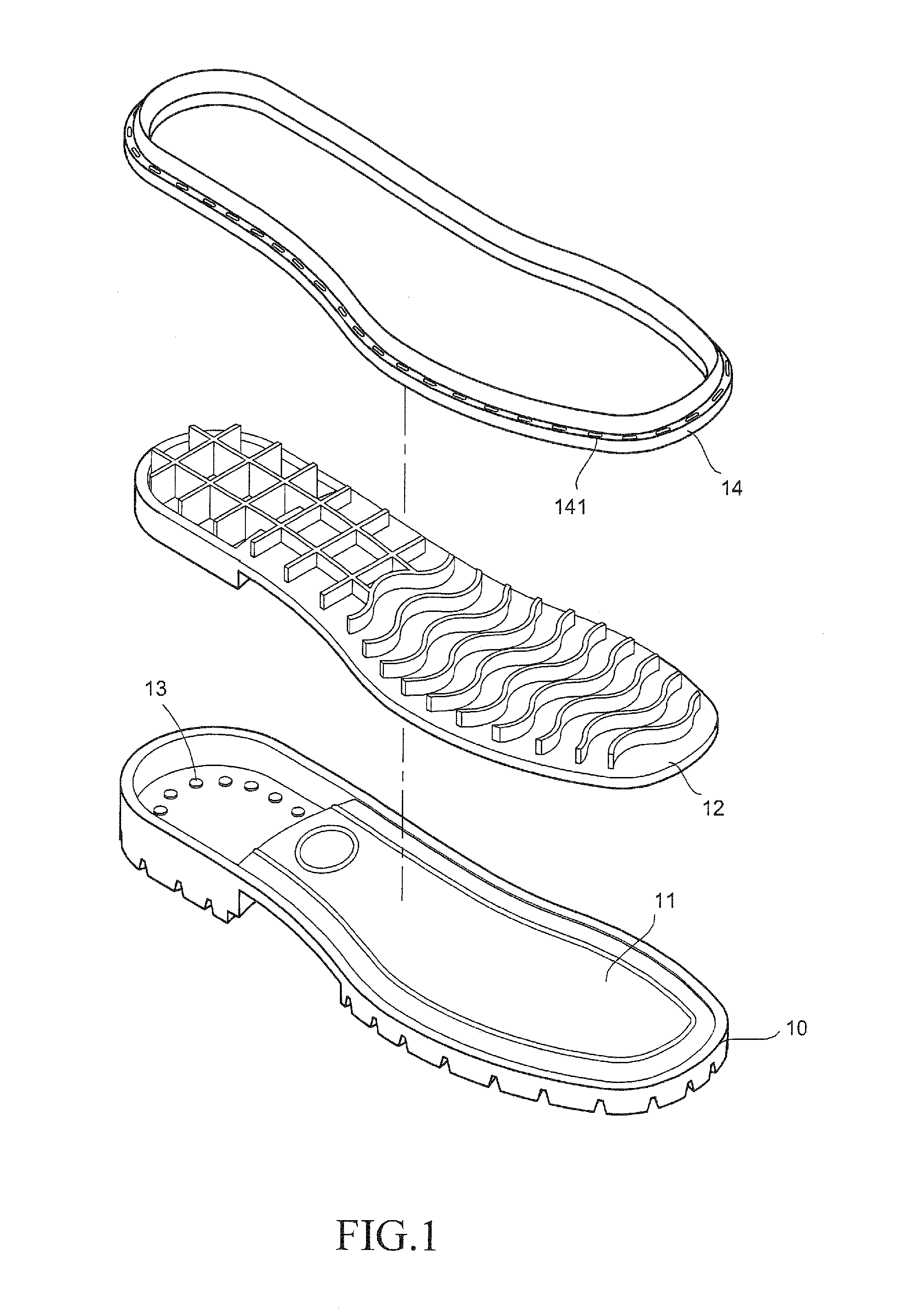

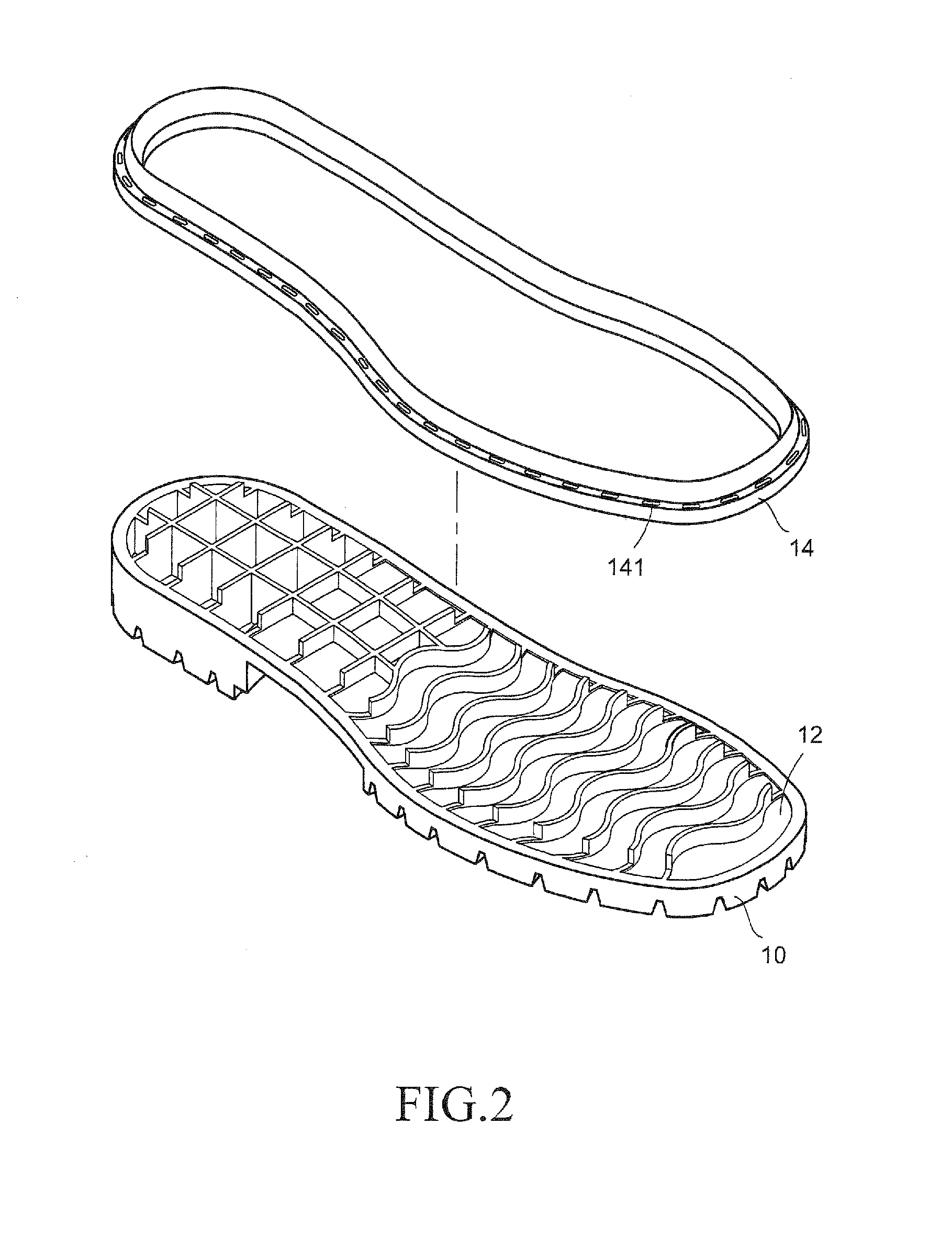

[0016]As shown in FIGS. 1-4, an improved sole structure of the present invention comprises a main body 10 or outsole, an intermediate layer 12, and a decorative strip 14 for enveloping a periphery of the main body 10, in which the aforementioned components may be preformed or pre-molded before a bonding process begins. The main body 10 is principally made of fresh rubber material having good physical properties, with suitable and necessary additives or fillers for ease of molding. The main body 10 has a bottom surface formed with a pattern of ribs for providing anti-slip function and a top surface defining a recess 11, the depth of which varies along the main body, in which each portion, such as heel portion or sole portion, may have a specific depth.

[0017]An intermediate layer 12, being...

PUM

| Property | Measurement | Unit |

|---|---|---|

| physical properties | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com