Line Element Lead-Through with Support Structure

a support structure and lead-through technology, applied in the direction of pipes, combustion processes, lighting and heating apparatus, etc., can solve the problems of difficult lead-through openings for cables, pipes and the like, uncertain skilled tradesmen, etc., and achieve the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

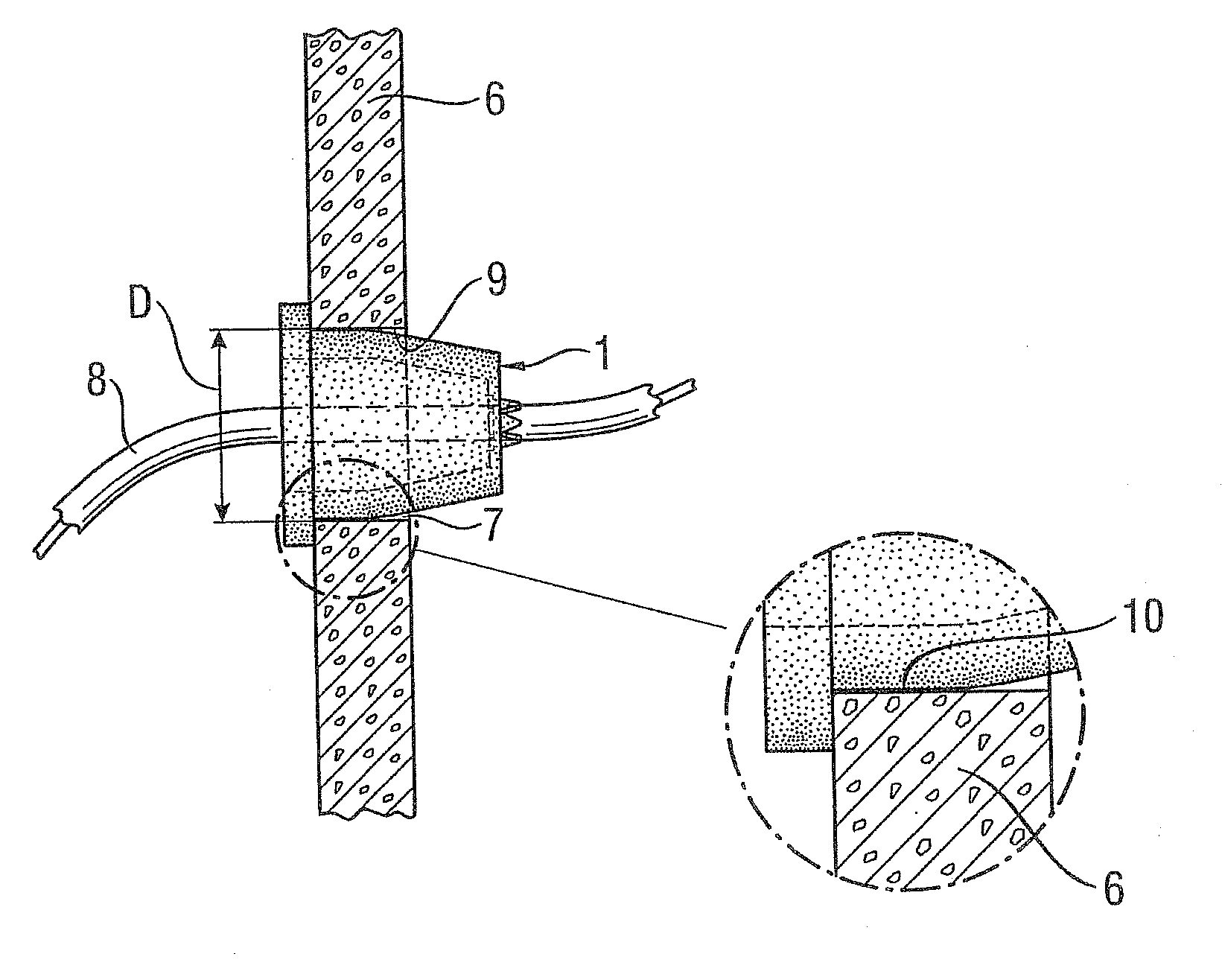

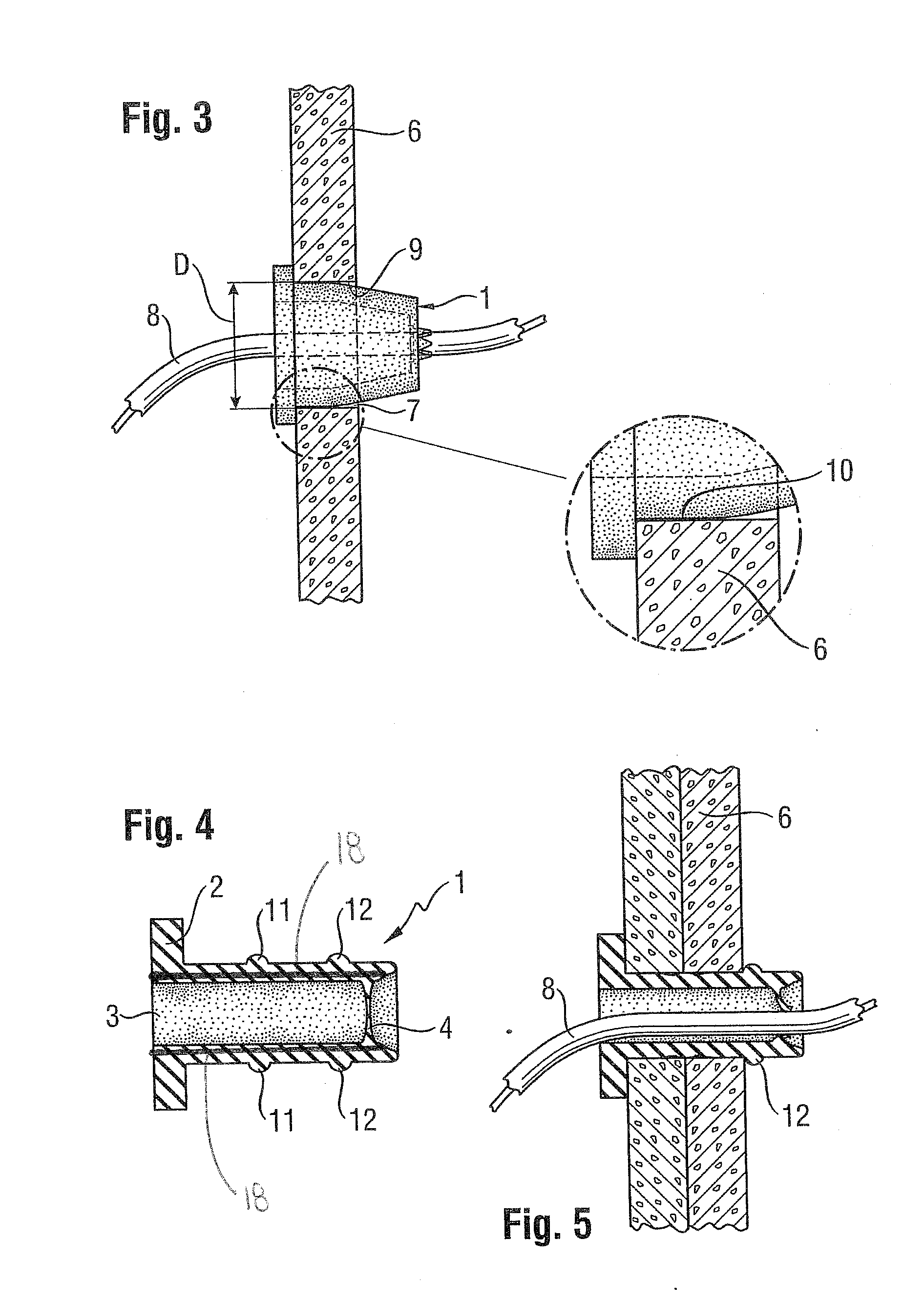

Embodiment Construction

[0053]In the sense of one or more embodiments of the present invention, the following definitions are used:[0054]“elastically deformable” means that the material of which the line element lead-through is made of is sufficiently elastic so that pressing it together is possible without problems, i.e., without exerting a great deal of force, say by hand, and the line element lead-through again assumes its original shape;[0055]“form fitting” means that the line element lead-through contacts the inner wall of the component lead-through directly not only in one spot but over a certain area and forms a contact surface;[0056]“intumescent material” means an intumescent foam material that carbonizes at temperatures starting at approximately 150° C. and / or the effect of flame with multiple increases in volume; an intumescent material according to one or more embodiments of the present invention that can be used is described, for example, in DE 3917518 or U.S. Pat. No. 3,574,664;[0057]“ash form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com