Bullet and fragmentation resistant vests and layered fabrics

a technology of layered fabrics and fabric layers, applied in the field of fabric fabric binding and fabric binding, can solve the problems of inconvenience and sometimes impracticality for end users, and achieve the effect of maximum freedom of movemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

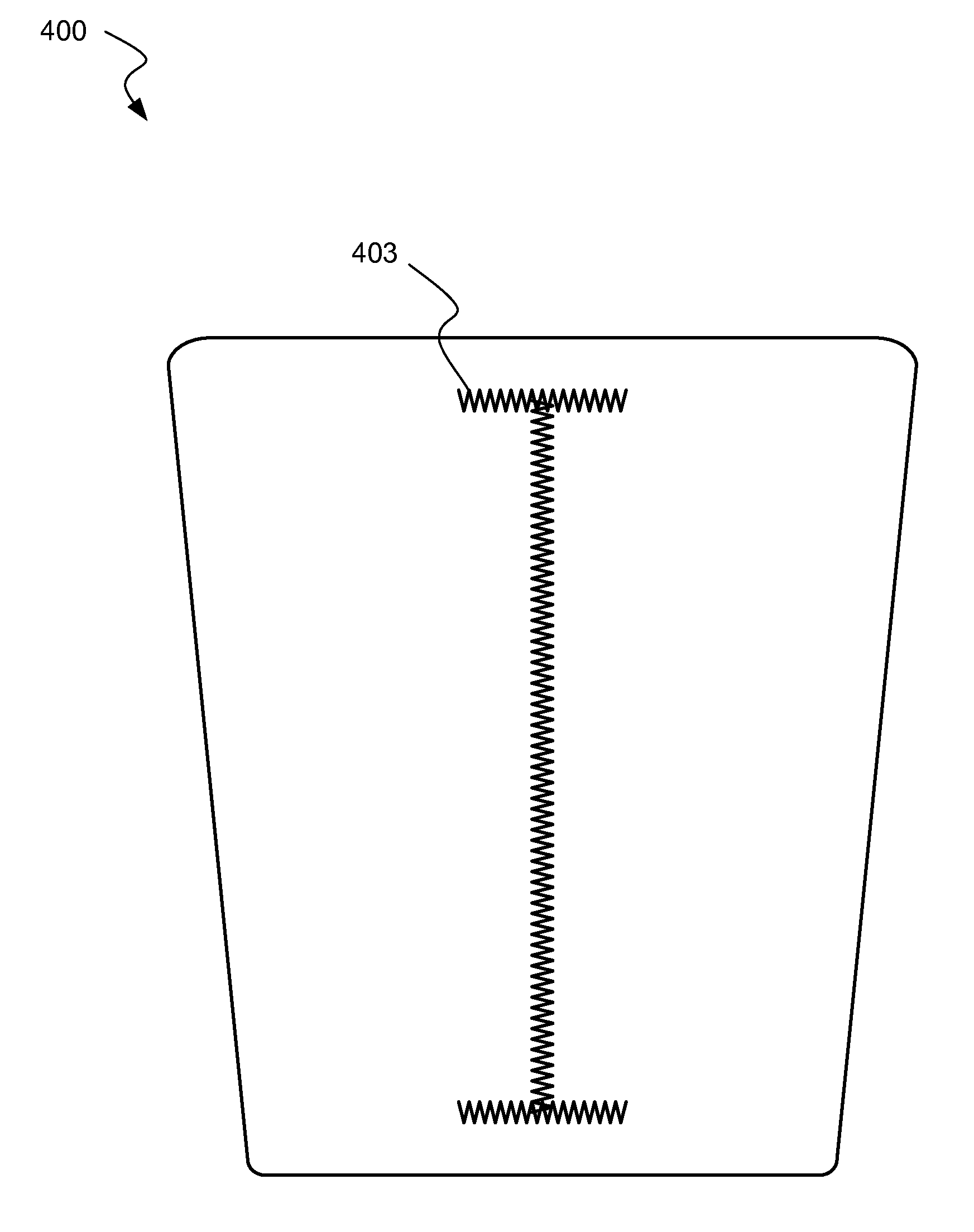

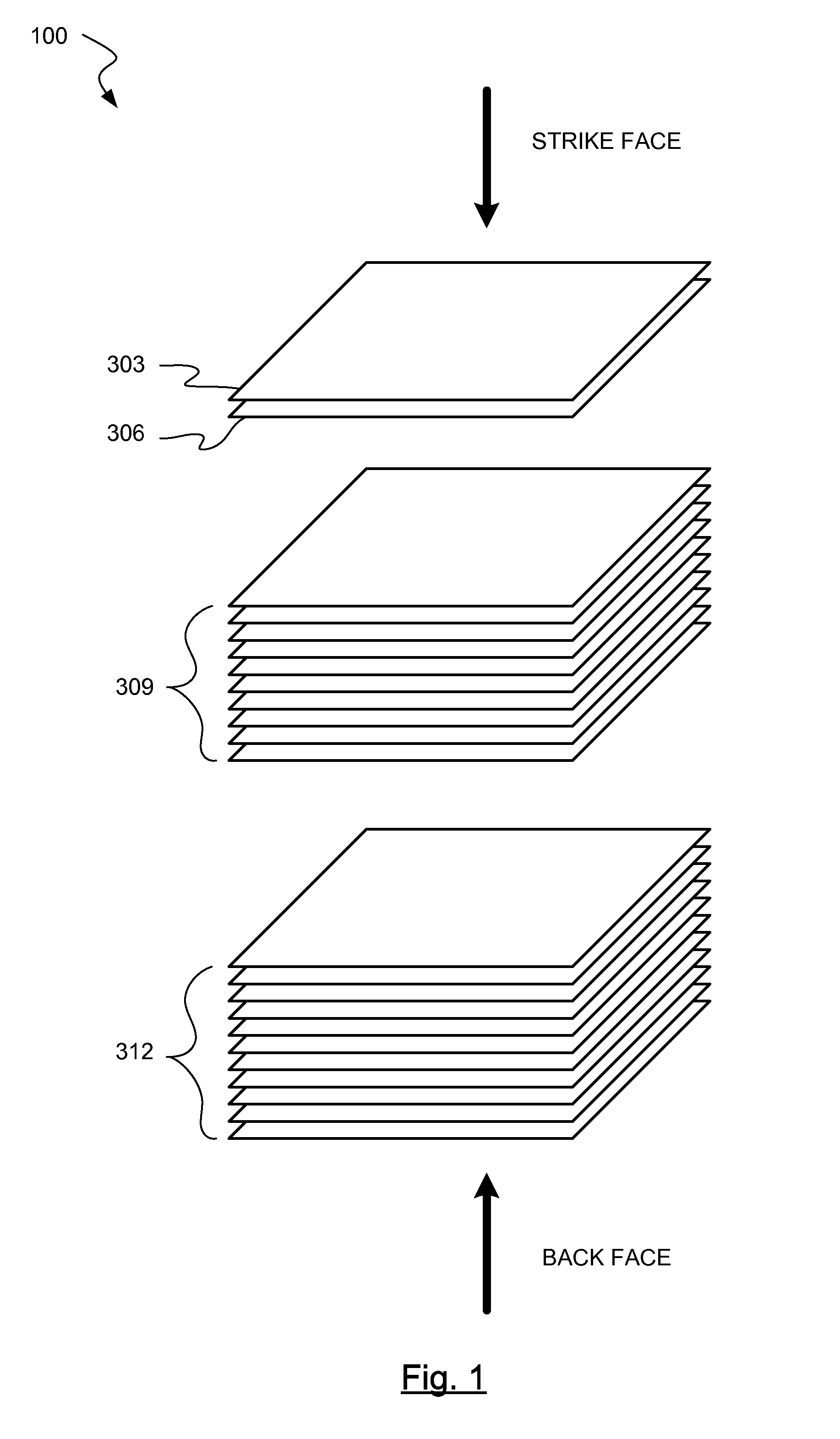

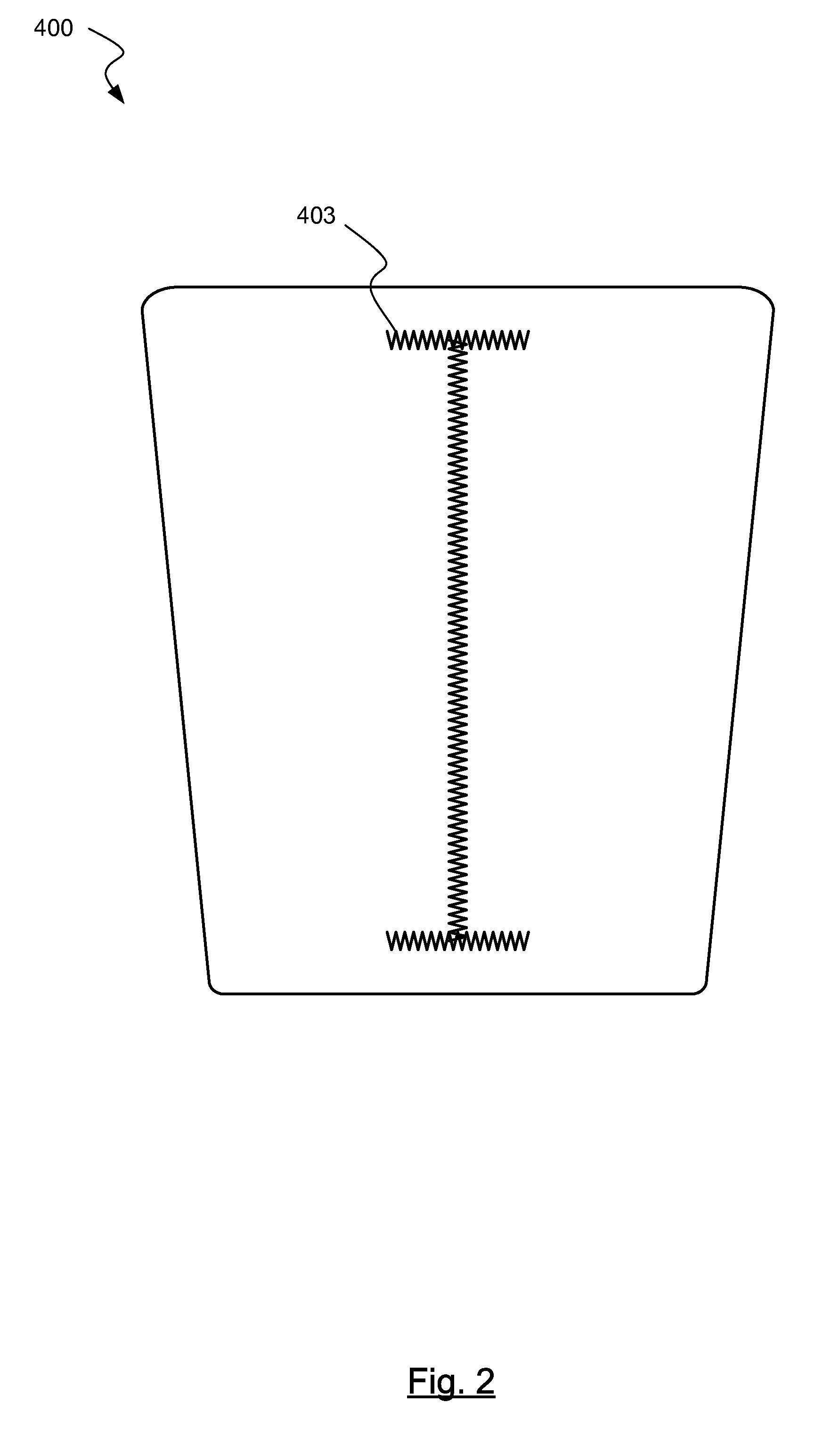

[0013]Embodiments of the present invention provide bullet and fragmentation resistant vests and layered fabrics, as well as methods for their construction. The vests of the invention may consist of multiple subcomponents, including, merely by way of example, a carrier vest and ballistic packs. The carrier vest may include carrier sections which accept insertion of ballistic packs, with the ballistic packs providing the bullet and fragmentation resistant properties of the vest. These vests may be concealable beneath other clothing, and may be provided in various shapes, sizes, layer packages, colors, and with different markings per standard specifications, or in some instances, user specification. Layered fabrics, for example, blankets and construction materials for bullet and fragmentation resistant structures, both stationary (i.e., buildings) and mobile (i.e., vehicles), may also be provided by the invention in the same manner as ballistic packs of the invention.

[0014]In some embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com