False eyelashes

a false eyelash and eyelash technology, applied in the field of false eyelashes, can solve the problems of affecting the appearance of the eye, and requiring prudent attention, and achieve the effects of easy handling, good appearance, and good visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

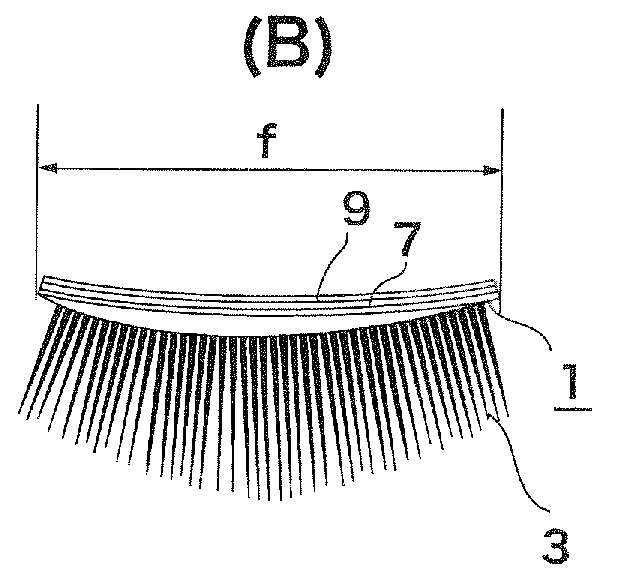

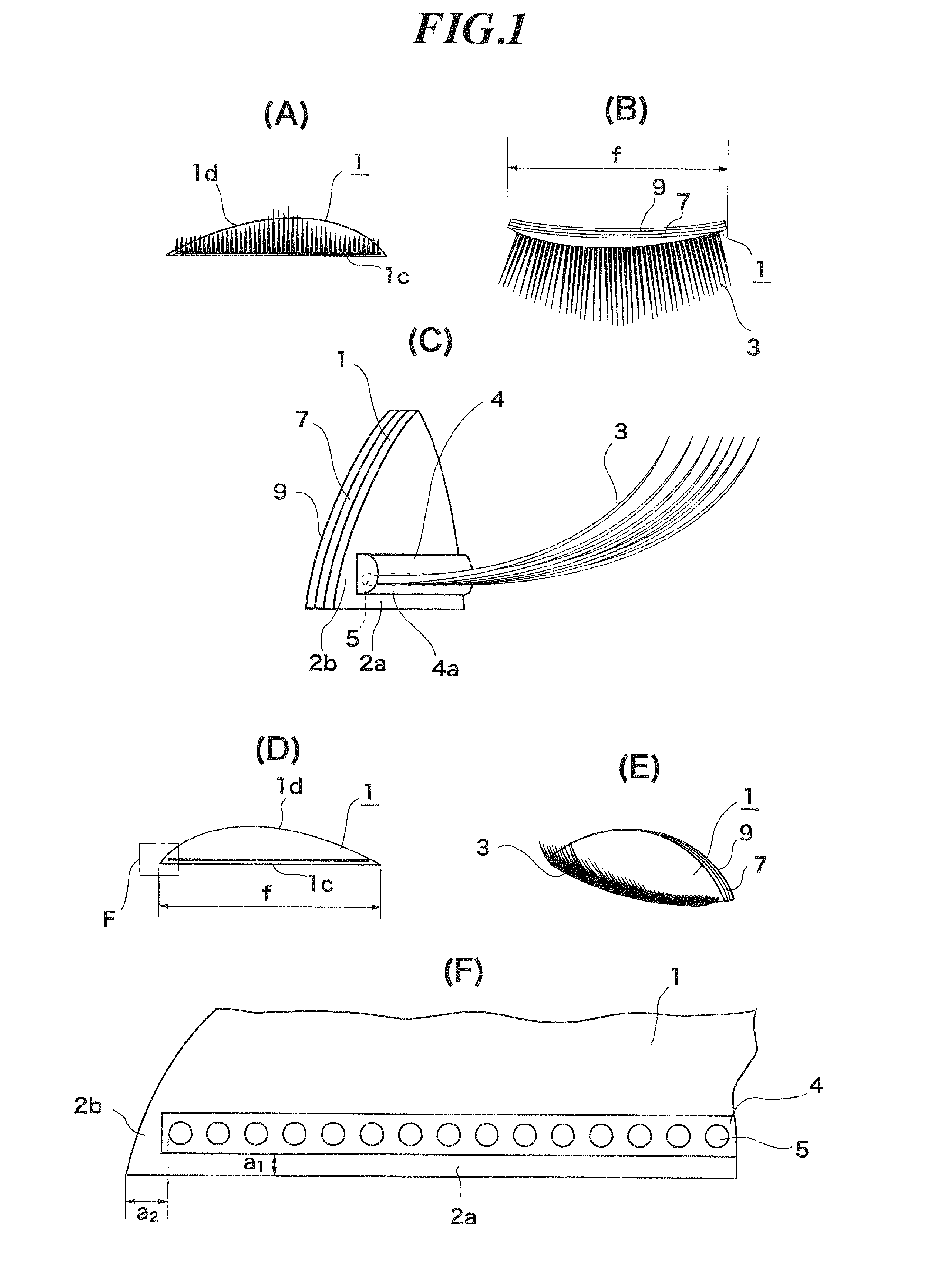

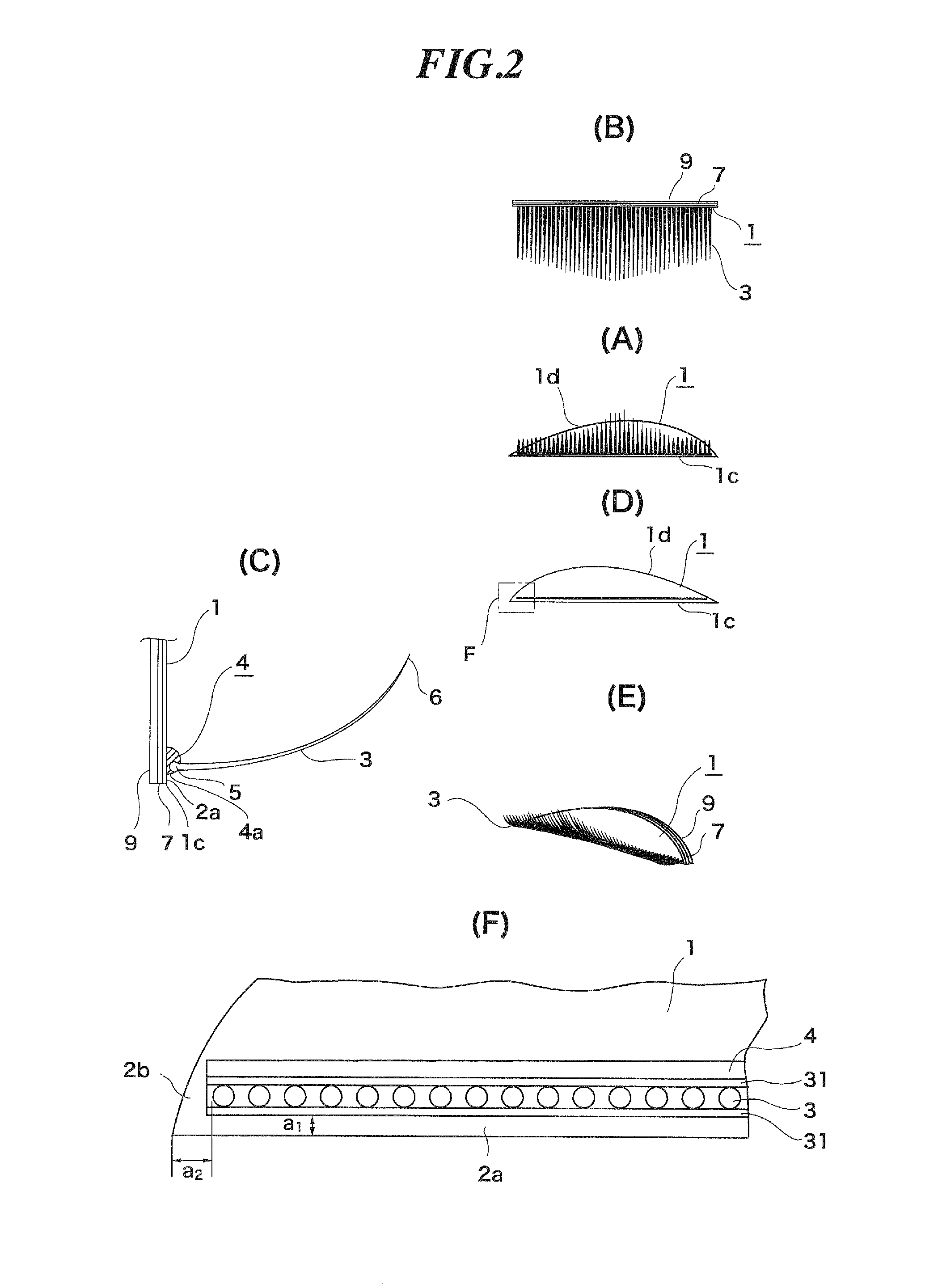

[0057]FIG. 2 shows a false eyelash according to the present invention. A base 1 of this embodiment is formed substantially planar, not customized. Hair segments 3 are adhered to the bonding layer 4 in a state wherein they are connected with each other by linear members 31. The structure excepting these points will be similar to the embodiment of FIG. 1.

[0058]FIG. 3 shows the base 1 used in the false eyelash of FIG. 2. The spaces will be explained here. The spaces 2a, 2b should be somewhat smaller than the diameter of a single hair. More particularly, a distance a1 should preferably be about 0.1-0.6 mm, and a distance a2 should preferably be about 0.1-0.6 mm. The base 1 in this embodiment has length L of about 26 mm, considering that an average eye size i of a Japanese (shown in FIG. 8(A)) is about 30 mm. Its maximum width is about 2.6 mm (WO for a single-edged eyelid, and about 4 mm (W2) for double-edged or internally double-edged eyelid. The base 1 may have various shapes depending...

third embodiment

[0060]The embodiments of FIG. 1 and FIG. 2 will be shipped, after being cut in a factory to a predetermined shape of a false eyelash, whereas the present invention shown in FIG. 5 is of a type wherein it is cut by the user. In this embodiment, the base 1 is cut into a rectangular shape 1M that is larger than a predetermined false eyelash shape. For use, the user should cut by herself the base 1 of the false eyelash along a cutting line shown in FIG. 7. In FIG. 5(A), a reference numeral 1a denotes the base after having been cut. The structure excepting these points will be similar to the embodiment of FIG. 1.

[0061]Regarding the size of various parts of the false eyelash shown in

[0062]FIG. 5, the vertical length of a pre-use base 1 is about 20-30 mm (a) for business use, and about 10-05 mm (b) for personal use where it is cut near to the base end portion 1c. The lateral length (c) is about 10-40 mm in common. The longitudinal size (d) of the hair segment 3 is about 2-12 mm. Each hair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com