Connection structure between thin wall stainless steel pipe and joint

a technology of stainless steel pipe and connection structure, which is applied in the direction of flanged joints, fluid pressure sealed joints, sleeve/socket joints, etc., can solve the problems of a large burden on the material supply of both the manufacturer and the joint, and achieve the effect of small storage space, small size, and cheap manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

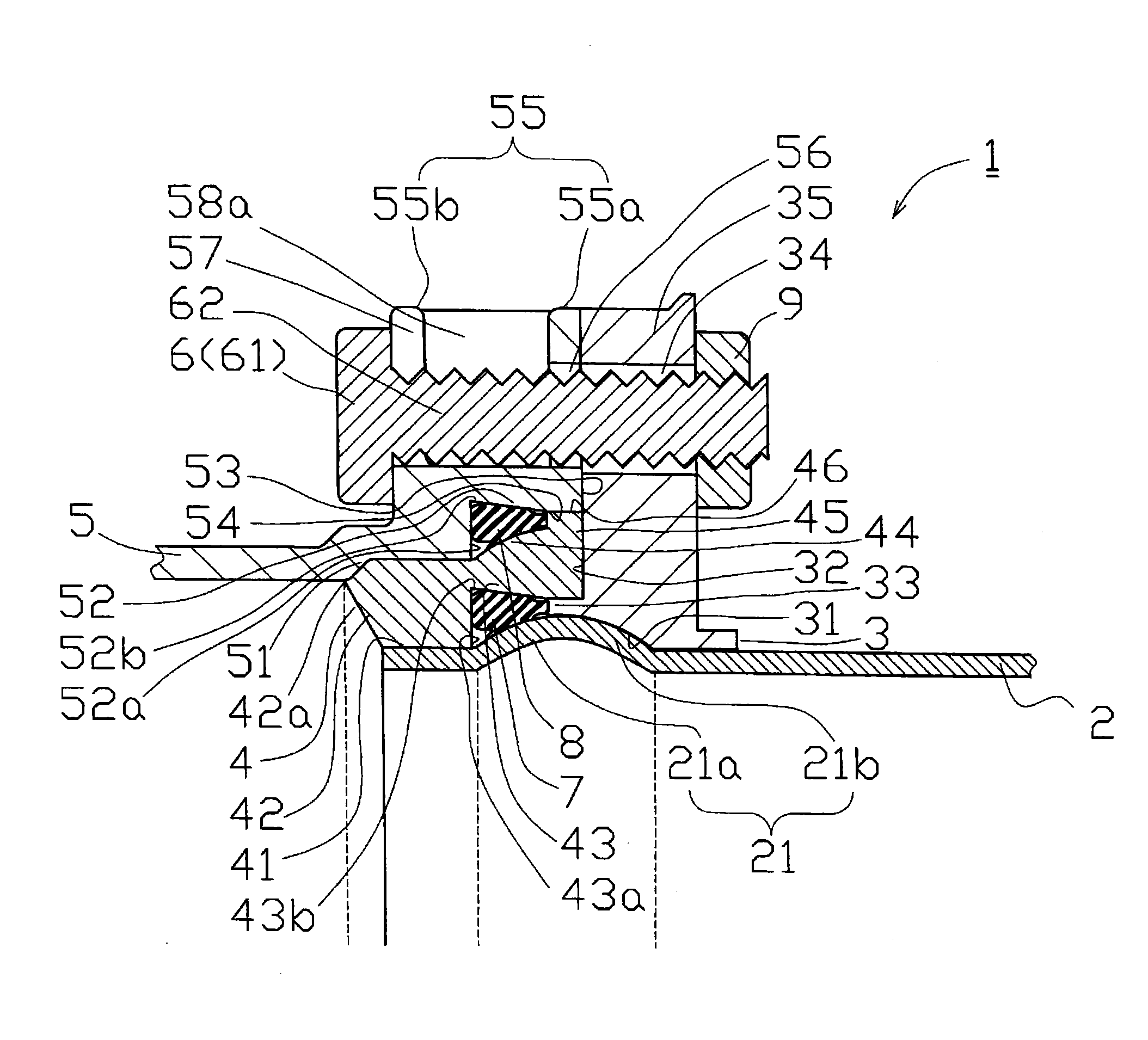

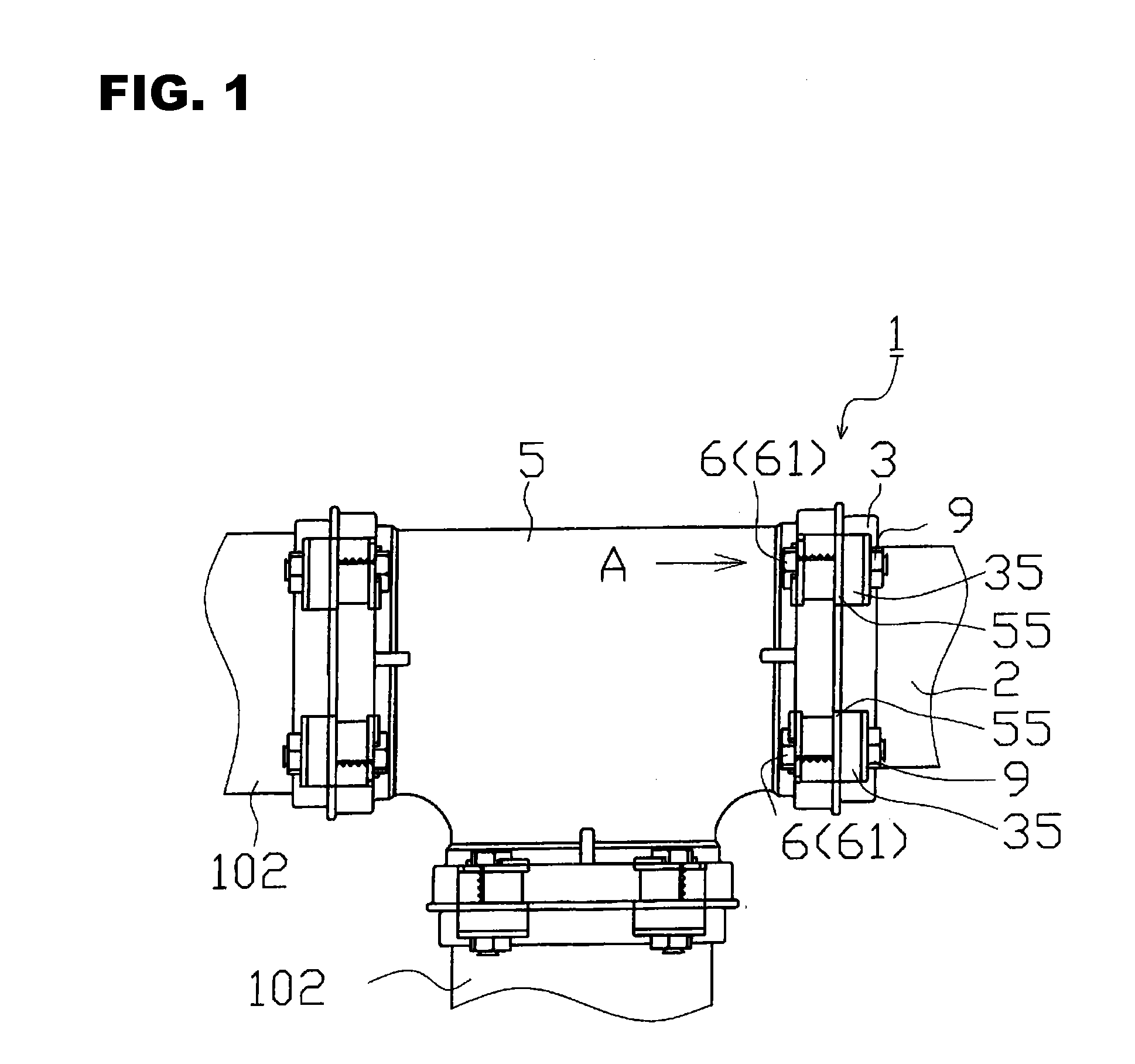

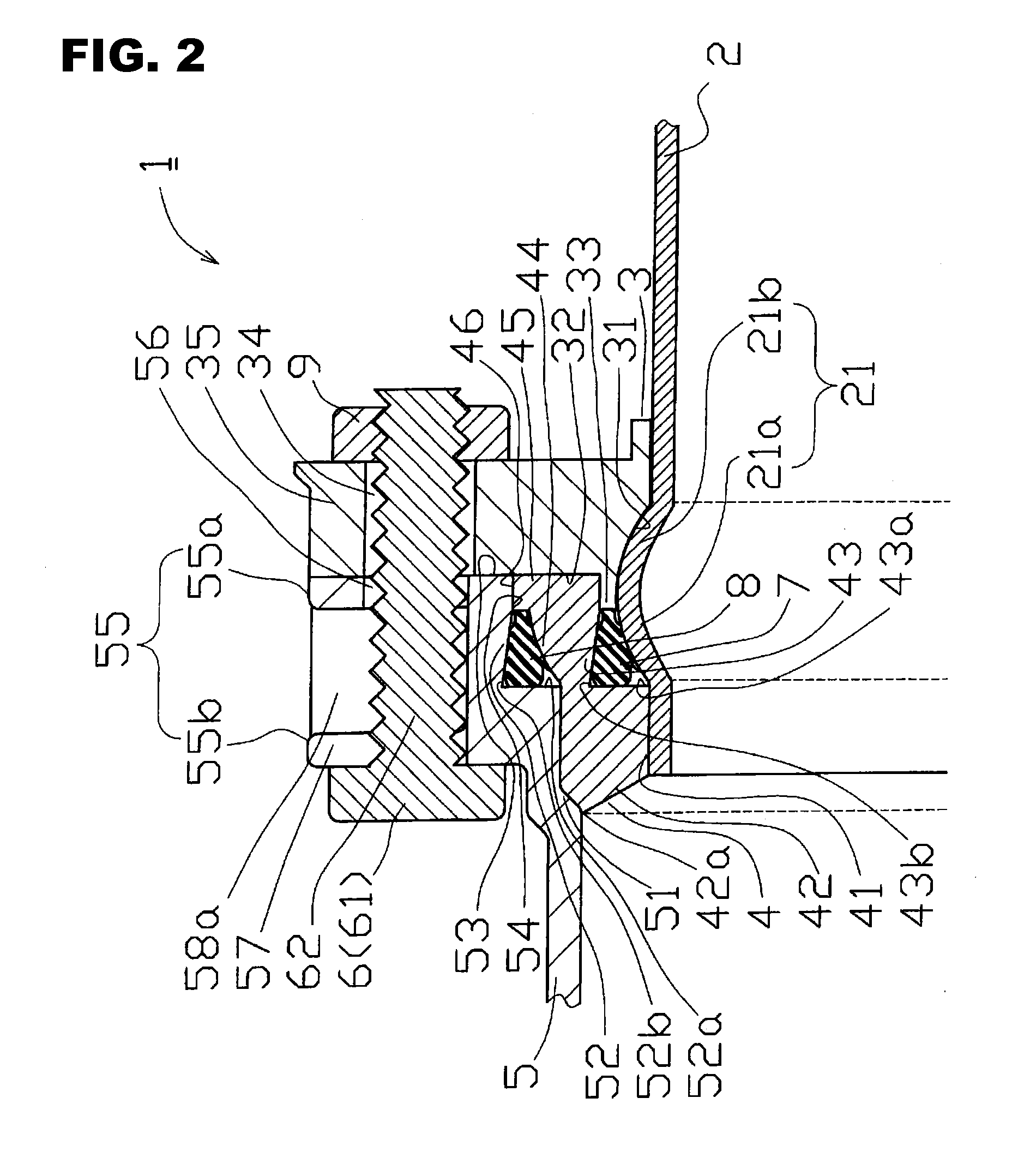

[0025]Hereinafter, an embodiment of the present invention will be described with reference to the accompanying drawings. A connection structure between a thin wall stainless steel pipe and a joint (hereinafter, simply referred to as “connection structure”) 1 is mainly constructed by a thin wall stainless steel pipe 2, a sandwiching portion 3, a joint spacer 4, a joint 5 and a bolt 6. The connection structure 1 can connect the joint 5, and the thin wall stainless steel pipe 2 having a pipe diameter which does not comply with the joint 5 while holding airtightness.

[0026]As shown in FIG. 2, the thin wall stainless steel pipe 2 is a steel pipe which is made of a stainless steel and has a pipe thickness between 0.7 mm and 3 mm, and a swelling portion 21 which is constructed by two inclined surfaces 21a and 21b and swells annularly in an outside direction is formed in an outer periphery of an end portion of the steel pipe.

[0027]The sandwiching portion 3 is externally fitted to an end port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com