Gas Turbine Combustor

a combustor and gas turbine technology, applied in the direction of machines/engines, burner ignition devices, lighting and heating apparatus, etc., can solve the problems of reducing the starting ignition characteristics and flame propagation characteristics of gas turbines, and achieve the effect of improving the ignition characteristics and flame propagation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

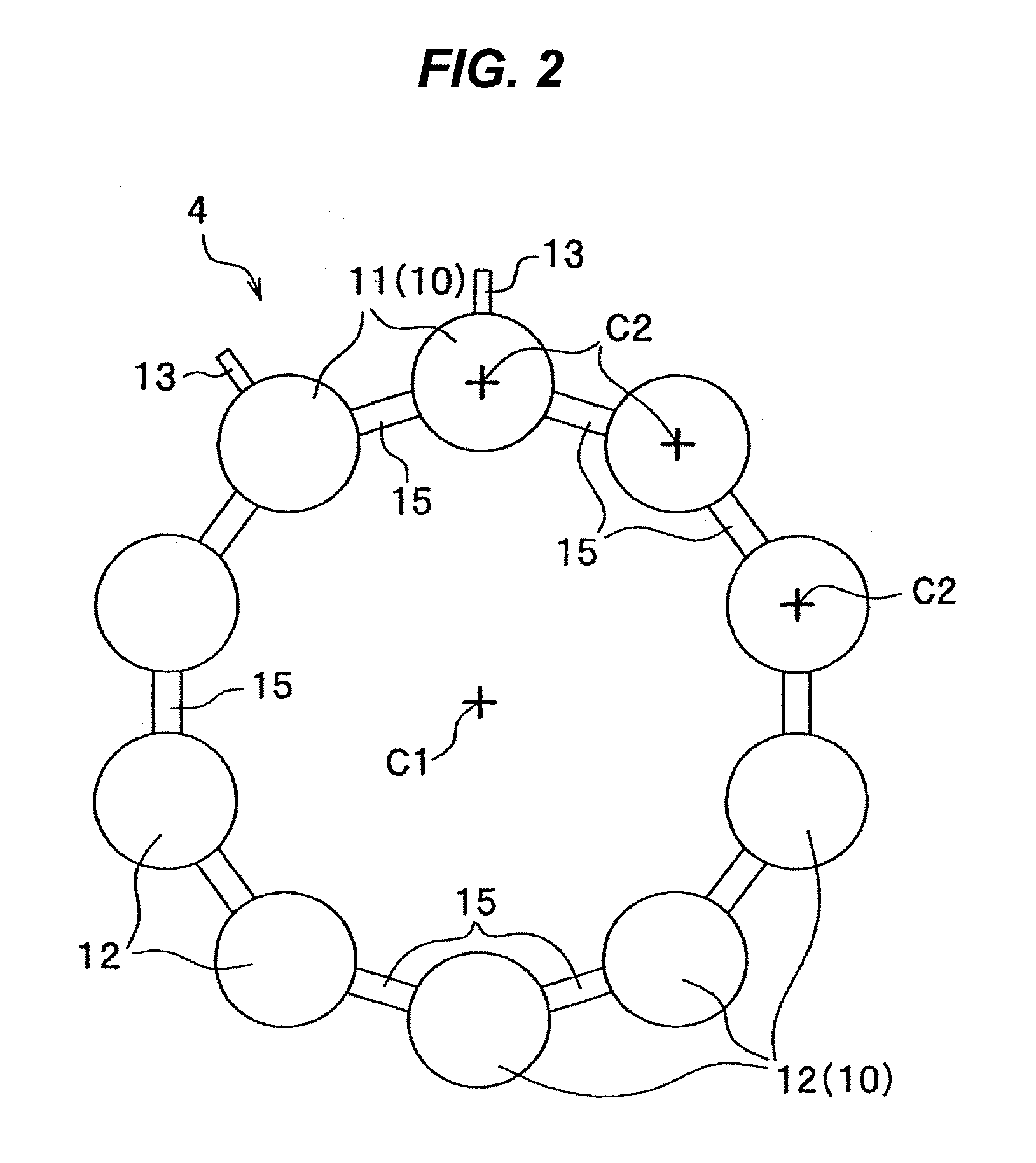

[0038]A gas turbine combustor 4 according to a first embodiment of the invention is described below referring to FIGS. 1 to 5.

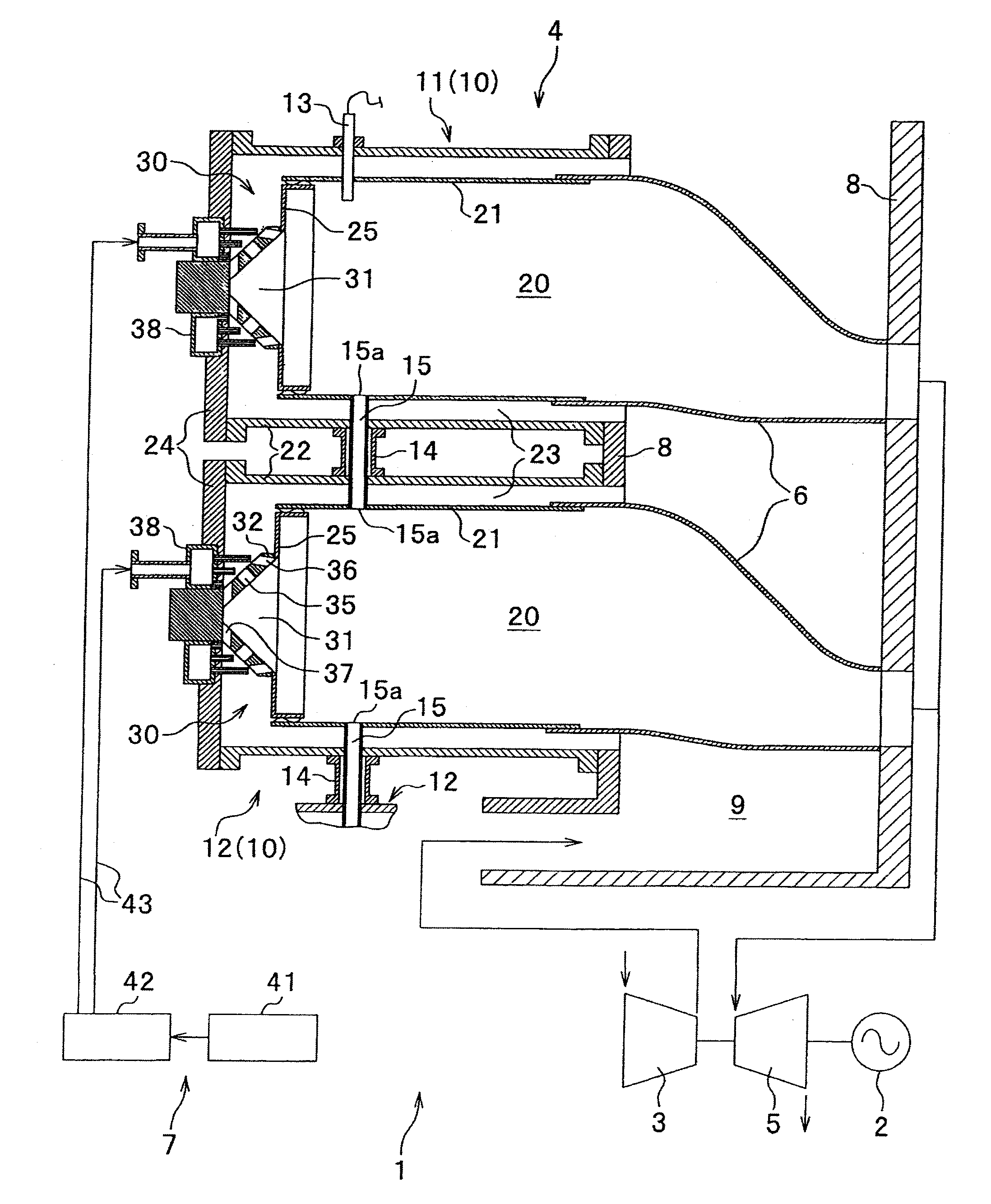

[0039]Referring to FIG. 1, a gas turbine plant equipped with a gas turbine 1 is a power-generating gas turbine plant including an electric power generator 2 driven by the gas turbine 1.

[0040]The gas turbine 1 includes: a compressor 3 that compresses air; a gas turbine combustor 4 that creates combustion gases by burning a fuel by means of combustion air which is part of the compressed air obtained in the compressor 3; a turbine 5 that rotates upon being driven by the high-temperature high-pressure combustion gases created by the gas turbine combustor 4; transition pieces 6 that guide the combustion gases from the gas turbine combustor 4 to the turbine 5; a fuel supply system 7 that supplies the fuel, a gaseous fuel such as liquefied natural gas, to the gas turbine combustor 4; and a casing 8 serving to support the gas turbine combustor 4 as well as to form a ...

second embodiment

[0082]A second embodiment of the present invention is described below referring to FIGS. 7 to 9. The second embodiment includes a plurality of main burners 50, 60 disposed at an outer peripheral side of the burner 30, with all other constituent elements of the embodiment being basically the same as in the first embodiment.

[0083]In the second embodiment and in third and fourth embodiments described later herein, description substantially of the same elements as those of the first embodiment is omitted or simplified, with attention being focused primarily upon differences. In addition, the same members as used in the first embodiment, or corresponding members in each of the second to fourth embodiments are each assigned the same reference number or symbol as appropriate. The second to fourth embodiments yield substantially the same operation and effect as those of the first embodiment.

[0084]Furthermore, the mixing chamber walls, mixing chambers 31, and fuel nozzles in the second to fo...

third embodiment

[0107]A third embodiment of the present invention is described below referring to FIGS. 10 to 12.

[0108]Referring to FIGS. 10, 11, burners 70, 80 in combustors 10 equipped in a gas turbine combustor 4 according to the third embodiment include a pilot burner 70 equivalent to the burner 30 in the second embodiment, and a main burner 80.

[0109]The pilot burner 70 includes a mixing chamber wall 72 that forms a conical mixing chamber 71 opening towards a downstream side in an axial direction. The pilot burner 70 also includes a fuel nozzle 79 serving as a central nozzle to supply a fuel. The mixing chamber wall 72 has a mixing chamber wall surface 73 formed into a conical shape, thereby forming the conical mixing chamber 71.

[0110]In the mixing chamber wall surface 72, a plurality of air introduction holes 75, 76 that form a plurality of air introduction passages for introducing combustion air independently or along with fuel into the mixing chamber 71, are arranged in two axial rows, namel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com