Robotic heliostat system and method of operation

a robotic heliostat and heliostat technology, applied in solar heat systems, solar heat collector safety, light and heating apparatus, etc., can solve the problems of increasing the capital and maintenance costs of the total system by 40-50%, affecting so as to prolong the effective life of various onboard energy storage mechanisms, improve the efficiency of the system, and reduce the effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

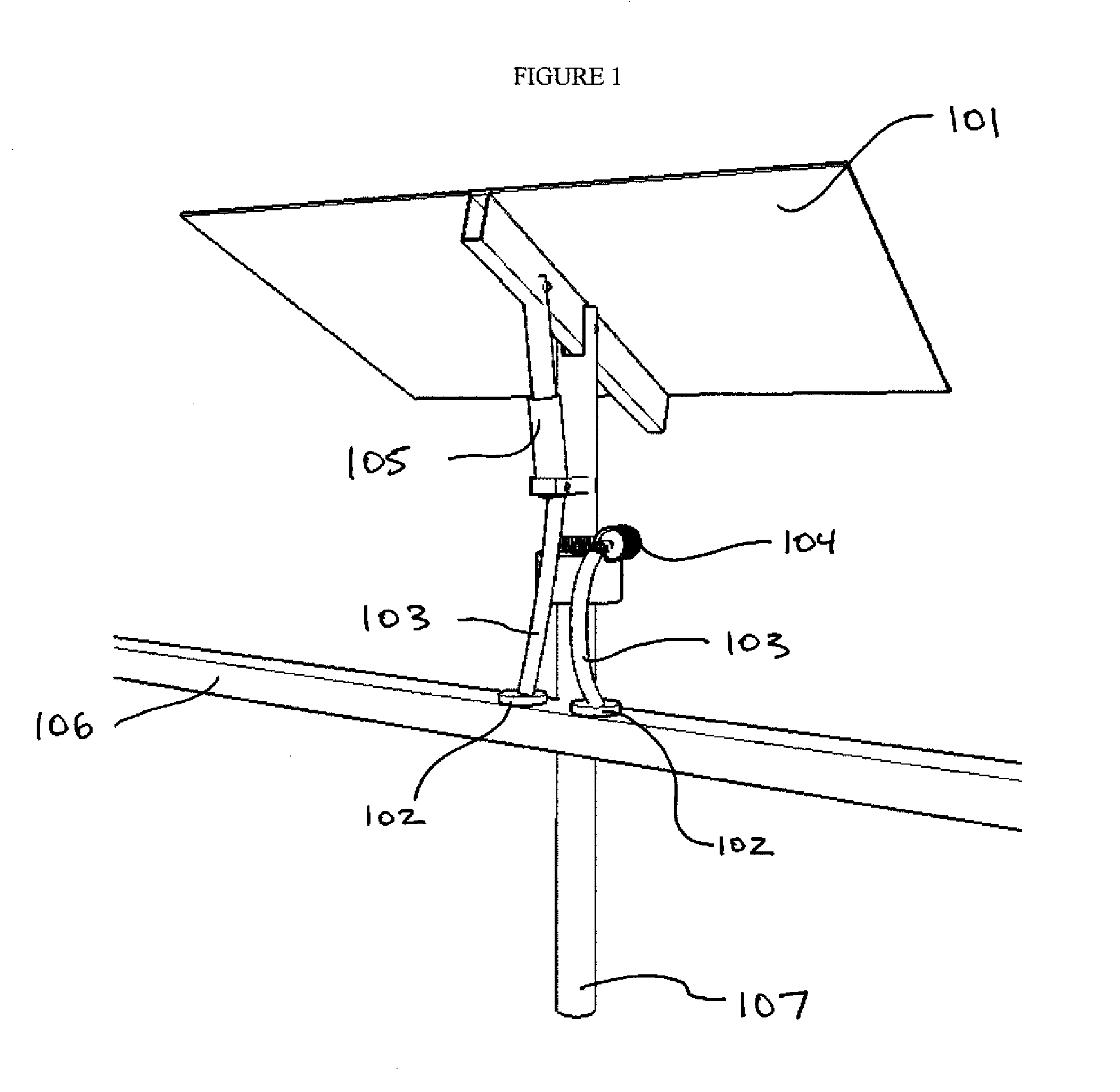

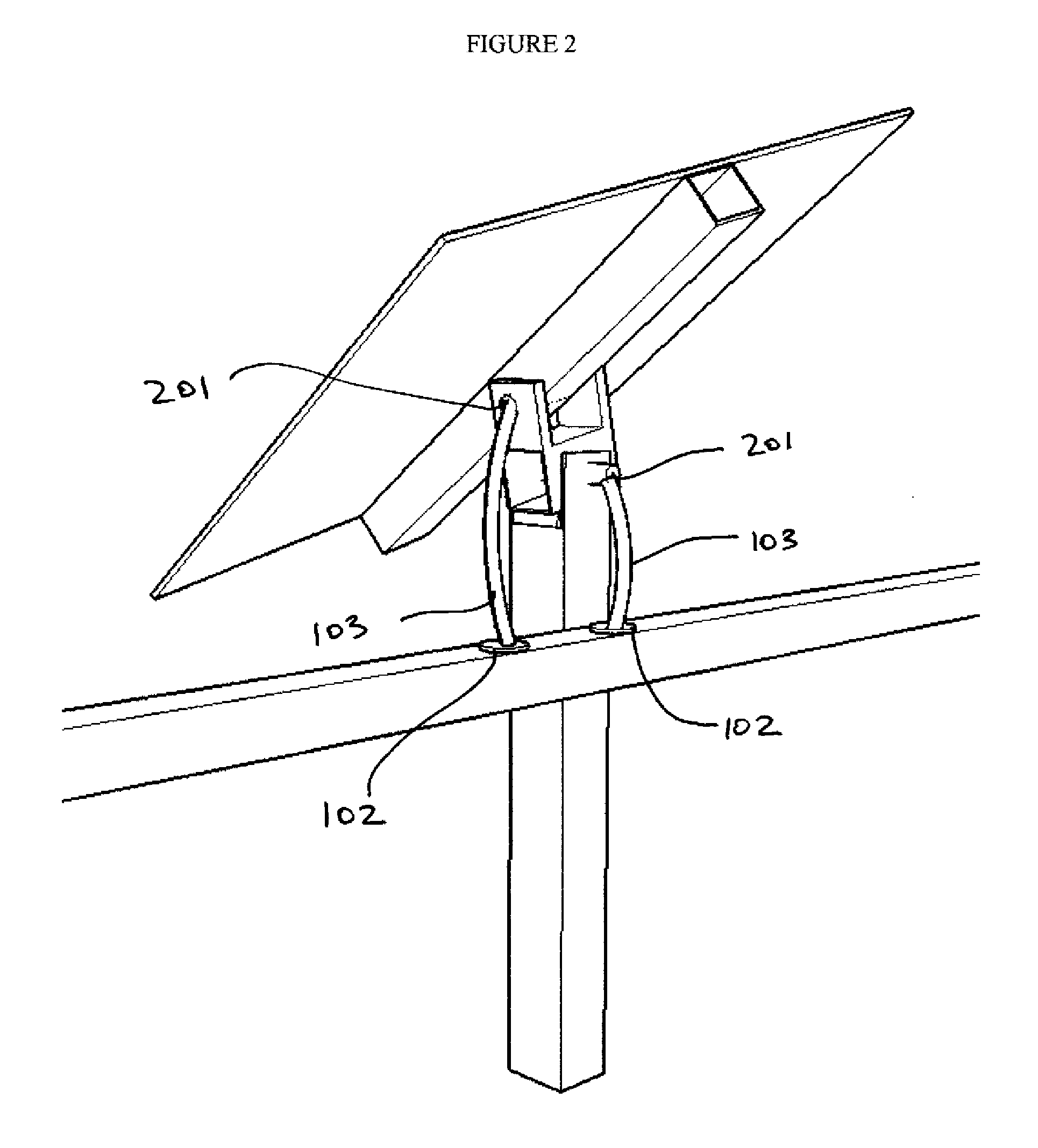

[0048]A preferred embodiment of the present invention is now described with reference to the figures where like reference numbers indicate identical or functionally similar elements. Also in the figures, the left most digits of each reference number corresponds to the figure in which the reference number is first used.

[0049]Reference in the specification to “one embodiment,”“a first embodiment,”“a second embodiment or to “an embodiment” (for example) means that a particular feature, structure, or characteristic described in connection with the embodiments is included in at least one embodiment of the invention. The appearances of the phrase “in one embodiment,”“a first embodiment,”“a second embodiment” or “an embodiment” (for example) in various places in the specification are not necessarily all referring to the same embodiment.

[0050]Some portions of the detailed description that follows are presented in terms of algorithms and symbolic representations of operations on data bits wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com