Retaining and Isolating Mechanisms for Magnets in a Magnetic Cleaning Tool

a technology of magnet retaining and isolating mechanism, which is applied in the direction of cleaning hollow articles, drilling pipes, drilling/well accessories, etc., can solve the problem of difficult removal from the mandrel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

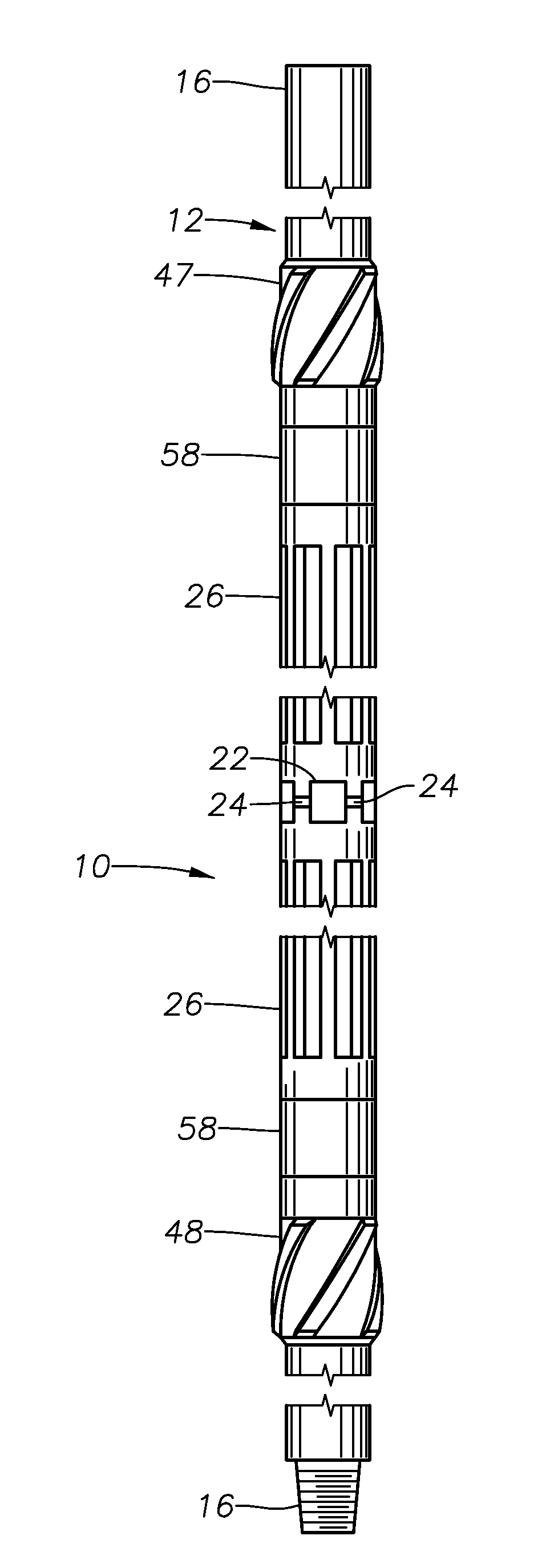

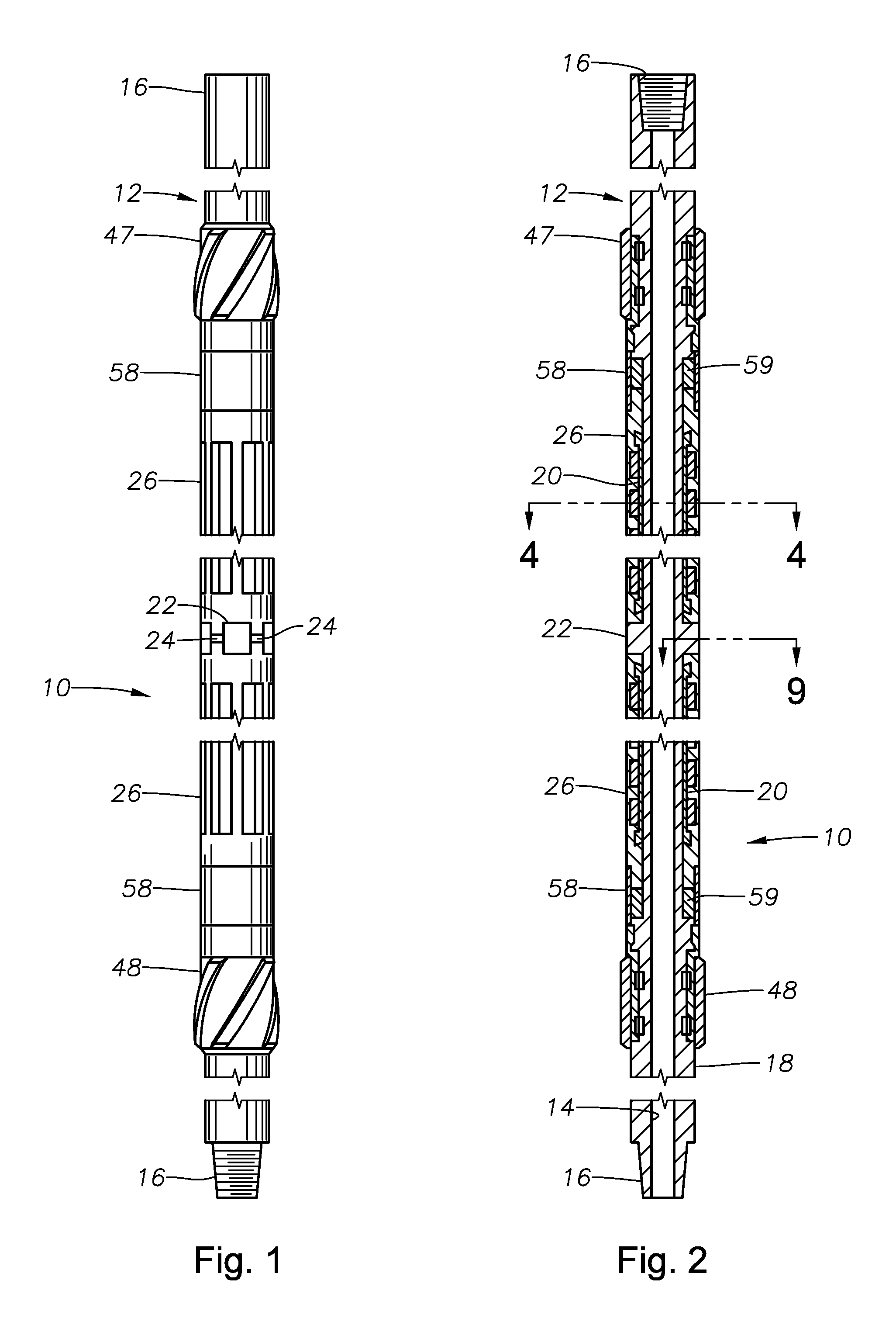

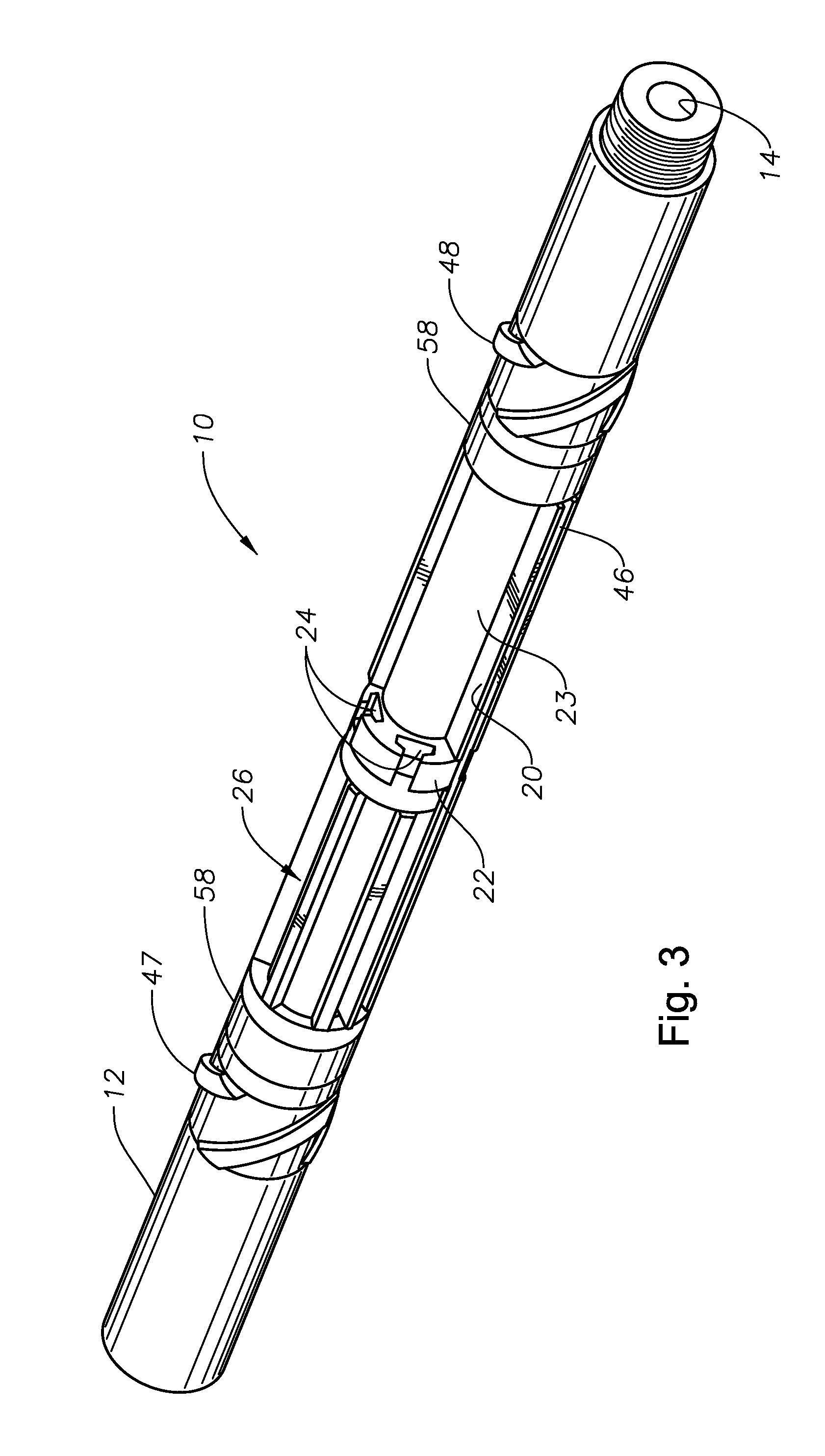

[0034]FIGS. 1-8 and 9 illustrate a first exemplary magnetic retrieval tool 10 that is constructed in accordance with the present invention. The tool 10 includes a cylindrical tool mandrel 12 which defines a central flowbore 14 (see FIG. 2) along its length. The tool mandrel 12 is provided with threaded connections 16 at its axial ends to permit the tool 10 to be incorporated into a downhole work string.

[0035]The tool mandrel 12 presents an outer radial surface 18 with a plurality of recessed pockets 20 formed therewithin. In the depicted embodiment, there are four pockets 20. Each of the pockets 20 is preferably axially elongated and arcuately curved, as shown in FIG. 3, wherein an empty pocket 20 is shown. In the depicted embodiment, each pocket 20 is located on the opposite side of the mandrel 12 from another pocket 20. In this embodiment, the pockets 20 provide an essentially semi-circular opening. The tool mandrel 12 also presents a radially-enlarged collar 22 which projects rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com