Vertical windmill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

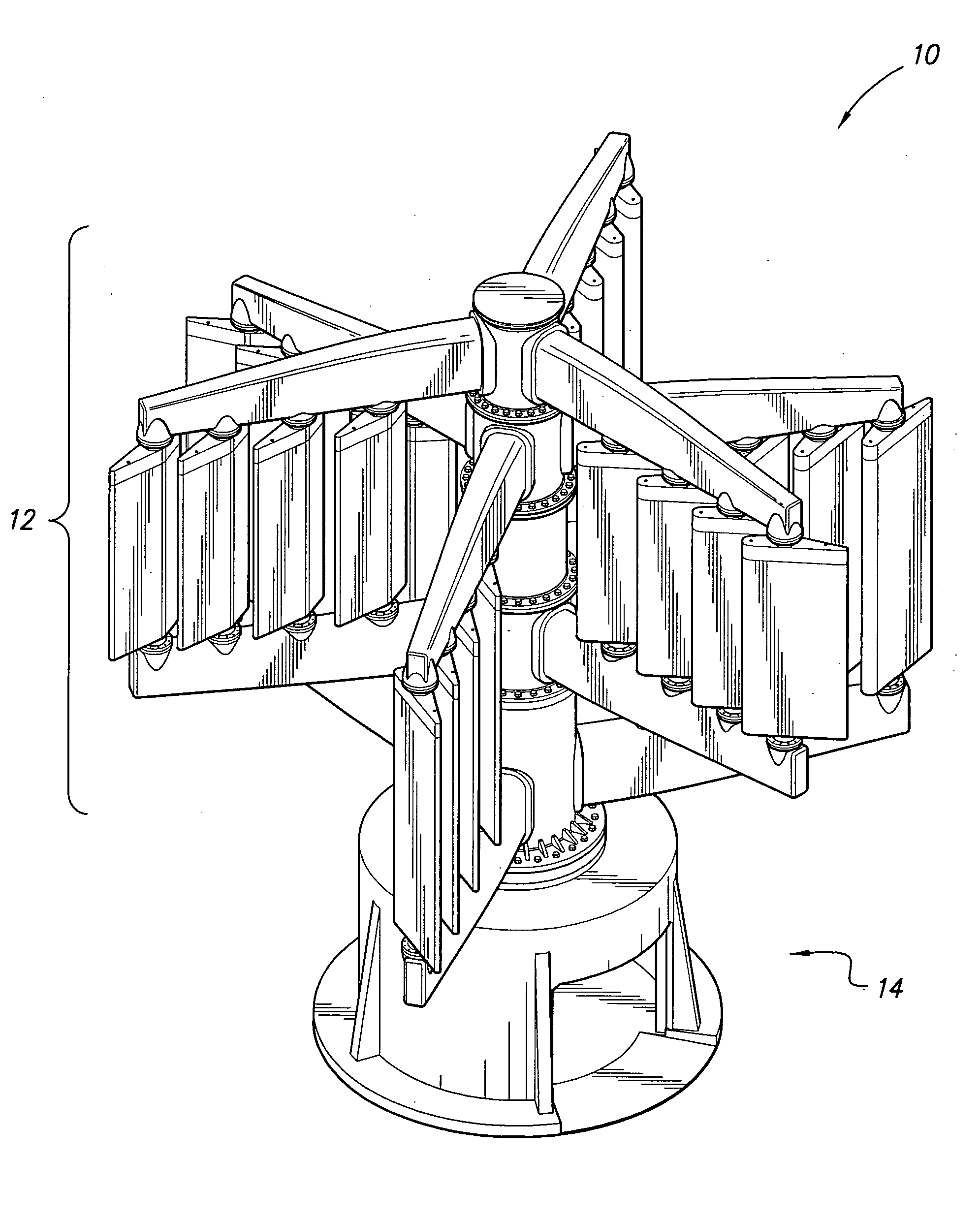

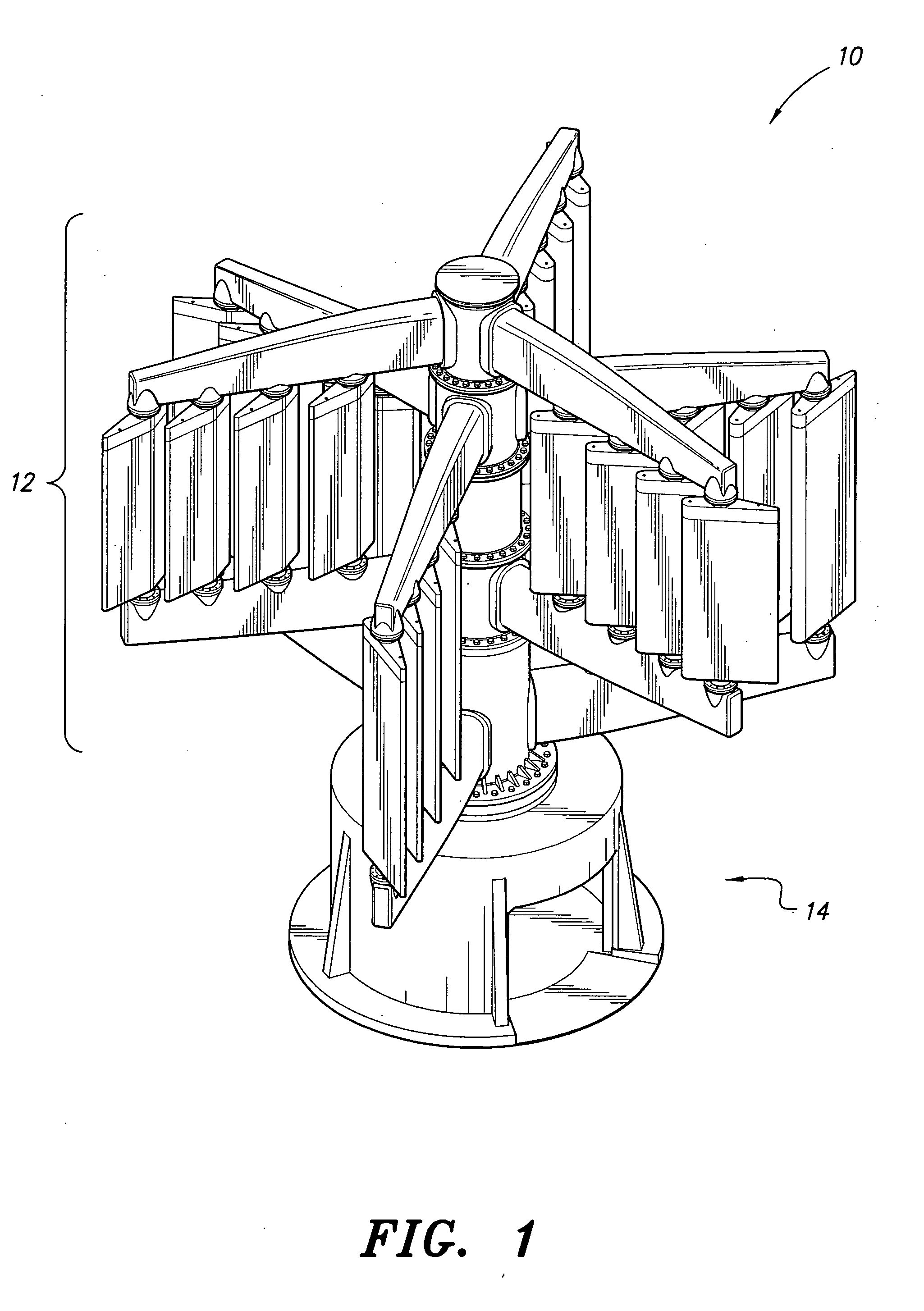

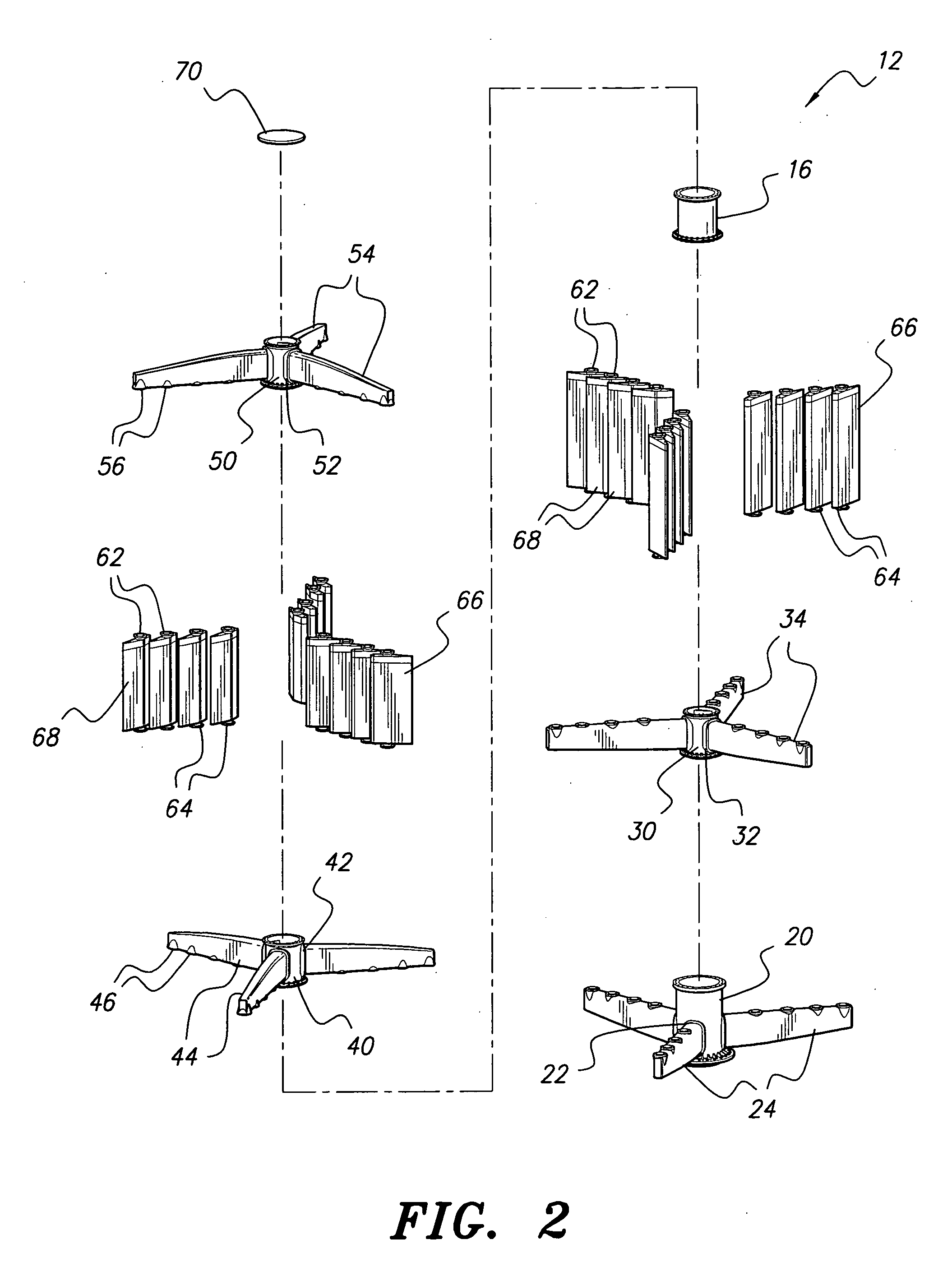

[0018]The present invention relates to a vertical windmill, generally referred to in the drawings by reference number 10, for maximal conversion of wind power into rotary force for producing usable energy. As shown in FIGS. 1 and 2, the vertical windmill 10 includes a rotatable wind wheel column 12 mounted to a base 14. The wind wheel column 12 includes a plurality of vertically stacked wind wheels angularly offset or staggered from each other. A plurality of vertically disposed vanes, wings or blades 60 mounted to the wind wheels utilizes wind power to provide the motive force for rotating the wind wheel column 12.

[0019]As shown in FIG. 2, the wind wheel column 12 includes, from the bottom, a lower or first hub 20 with angularly spaced mounting holes 24. The first hub 20 may be a substantially hollow cylinder with connection flanges disposed on the top and bottom to facilitate mounting thereof to subsequent hubs or hub sections and the base 14. Since the first hub 20 forms a base o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com