Exhaust gas recirculation device of engine

a technology of exhaust gas recirculation and engine, which is applied in the direction of combustion-air/fuel-air treatment, electric control, instruments, etc., can solve the problems of restricted low pressure and temperature of the exhaust gas introduced into the intake passage via the downstream exhaust gas recirculation passage, and the restriction of nitrogen oxide along with the combustion of fuel in the combustion chamber. , to achieve the effect of reducing the temperature of the flam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

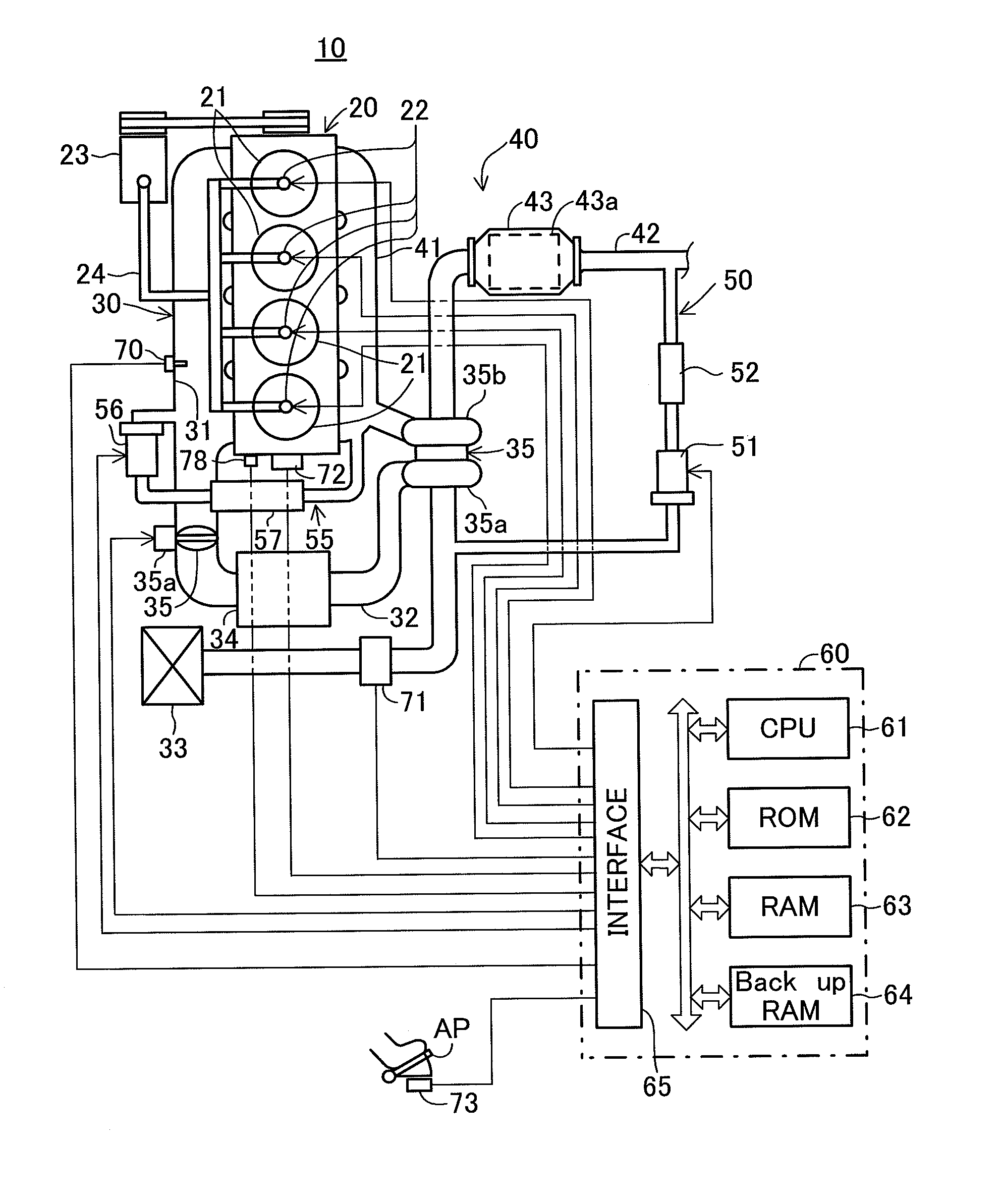

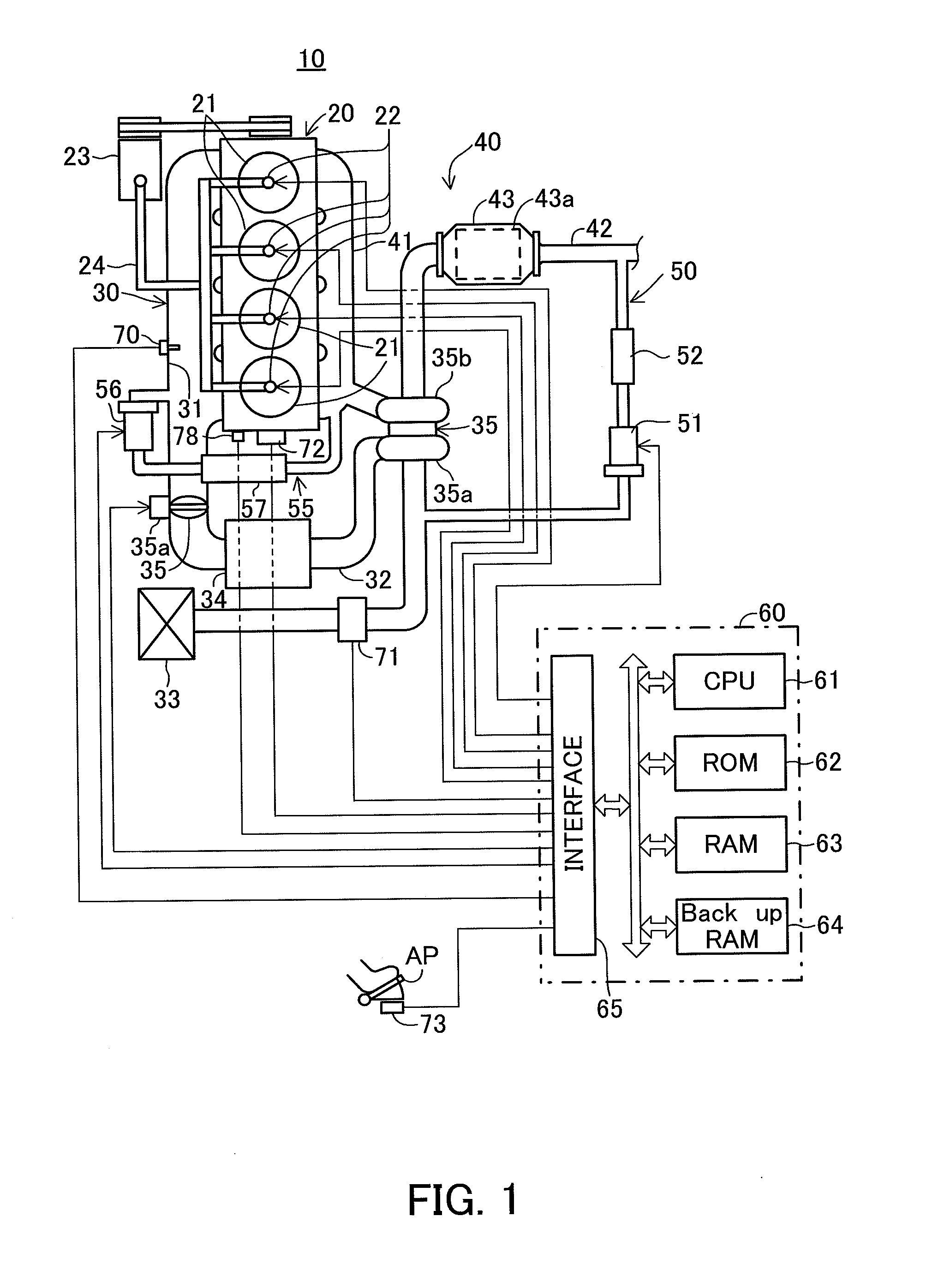

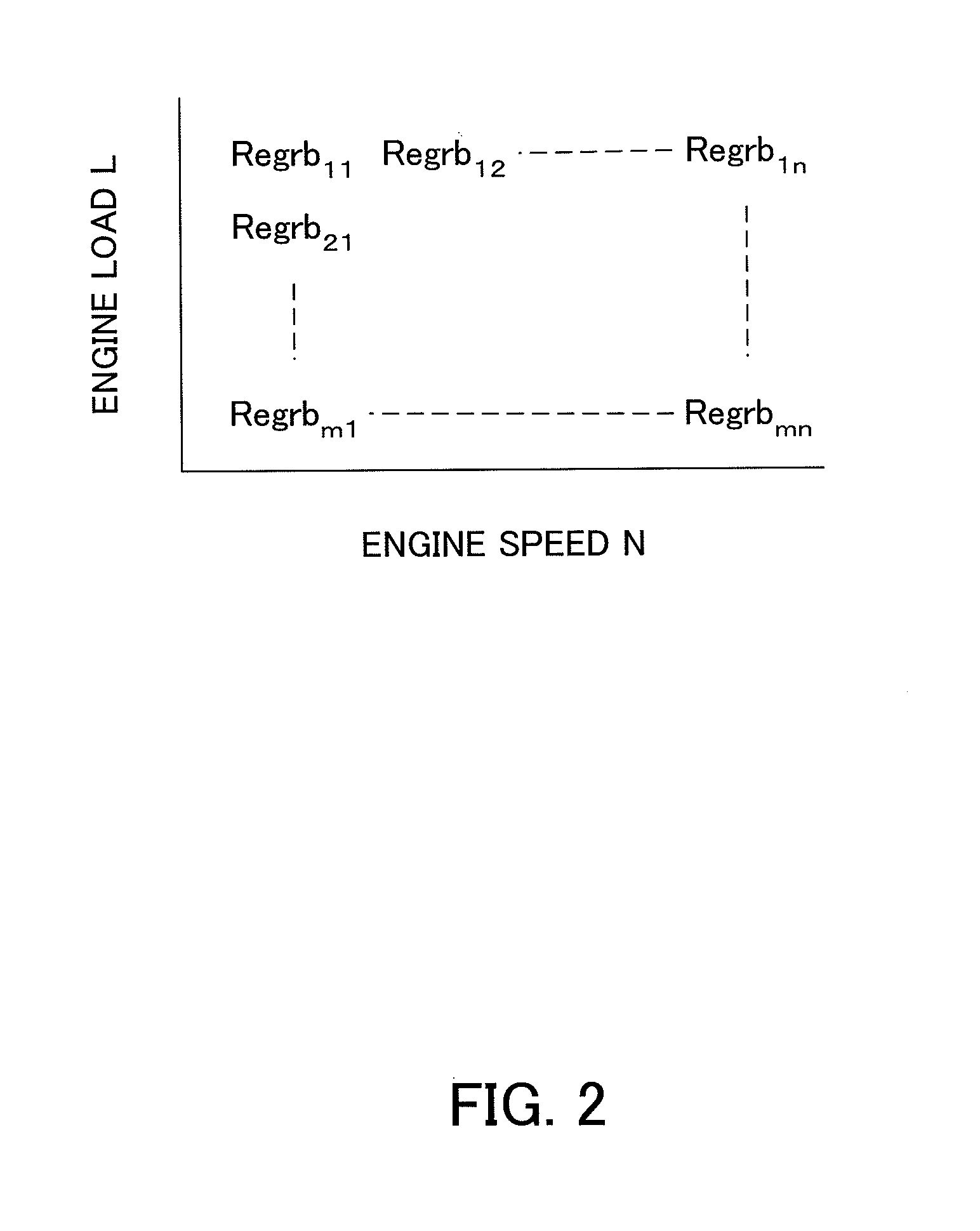

[0039]That is, in the first embodiment, most appropriate EGR ratios depending on the engine speed and the engine load (the detail of the most appropriate EGR ratio will be explained later) are previously obtained by an experiment, etc., and the EGR ratios are memorized in the ECU 60 as reference EGR ratios Regrb in the form of a map as a function of the engine speed N and the engine load L as shown in FIG. 2. During the operation of the engine, a reference EGR ratio Regrb is read from the map, depending on the engine speed N and the engine load L, and the reference EGR ratio is set as a target EGR ratio. The amount of the exhaust gas introduced into the intake passage 30 from the exhaust passage 40 via the first EGR passage 50 or the second EGR passage 55 is controlled by the first EGR control valve 51 or the second EGR control valve 56 such that an amount of the exhaust gas which can accomplish the target EGR ratio is introduced into the intake passage 30 from the exhaust passage 4...

second embodiment

[0074]It should be noted that in the second embodiment, the target EGR ratio may be set to an EGR ratio larger than the reference EGR ratio by a constant value, independently of the difference between the maximum flame temperature and the allowable upper limit flame temperature, i.e. the flame temperature difference or the target EGR ratio may be set to an EGR ratio larger than the reference EGR ratio, depending on the flame temperature difference. For example, in the case that the target EGR ratio is set to an EGR ratio larger than the reference EGR ratio, depending on the flame temperature difference, the target EGR ratio may be set to an EGR ratio which progressively increases as the flame temperature difference becomes large or the target EGR ratio may be set to an EGR ratio which continuously increases as the flame temperature difference becomes large. In this case, the concentration of the oxygen in the gas introduced into the combustion chamber is decreased as the maximum fla...

third embodiment

[0078]That is, in this embodiment (hereinafter, referred to as “third embodiment”), when the maximum flame temperature is higher than the allowable upper limit flame temperature, a reference EGR ratio Regrb is read from the map shown in FIG. 2, depending on the engine speed N and the engine load L and a reference EGR gas ratio Rb is read from the map shown in FIG. 3, depending on the engine speed N and the engine load L. Then, the first and second EGR gas amounts which can accomplish the reference EGR ratio and the reference EGR gas ratio, are calculated as reference first and second EGR gas amounts, respectively. Then, the reference first EGR gas amount calculated as explained above is set as the target first EGR gas amount. On the other hand, the target second EGR gas amount is set as follows.

[0079]That is, in the third embodiment, a reference oxygen concentration Cob is read from the map shown in FIG. 4, depending on the engine speed N and the engine load L and the reference oxyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com