Skylight roof assembly

a skylight and roof assembly technology, applied in skylights/domes, building roofs, building repairs, etc., can solve problems such as water leakage problems, water leakage problems around skylights, water leakage problems, etc., to reduce the time of roof cutting open

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

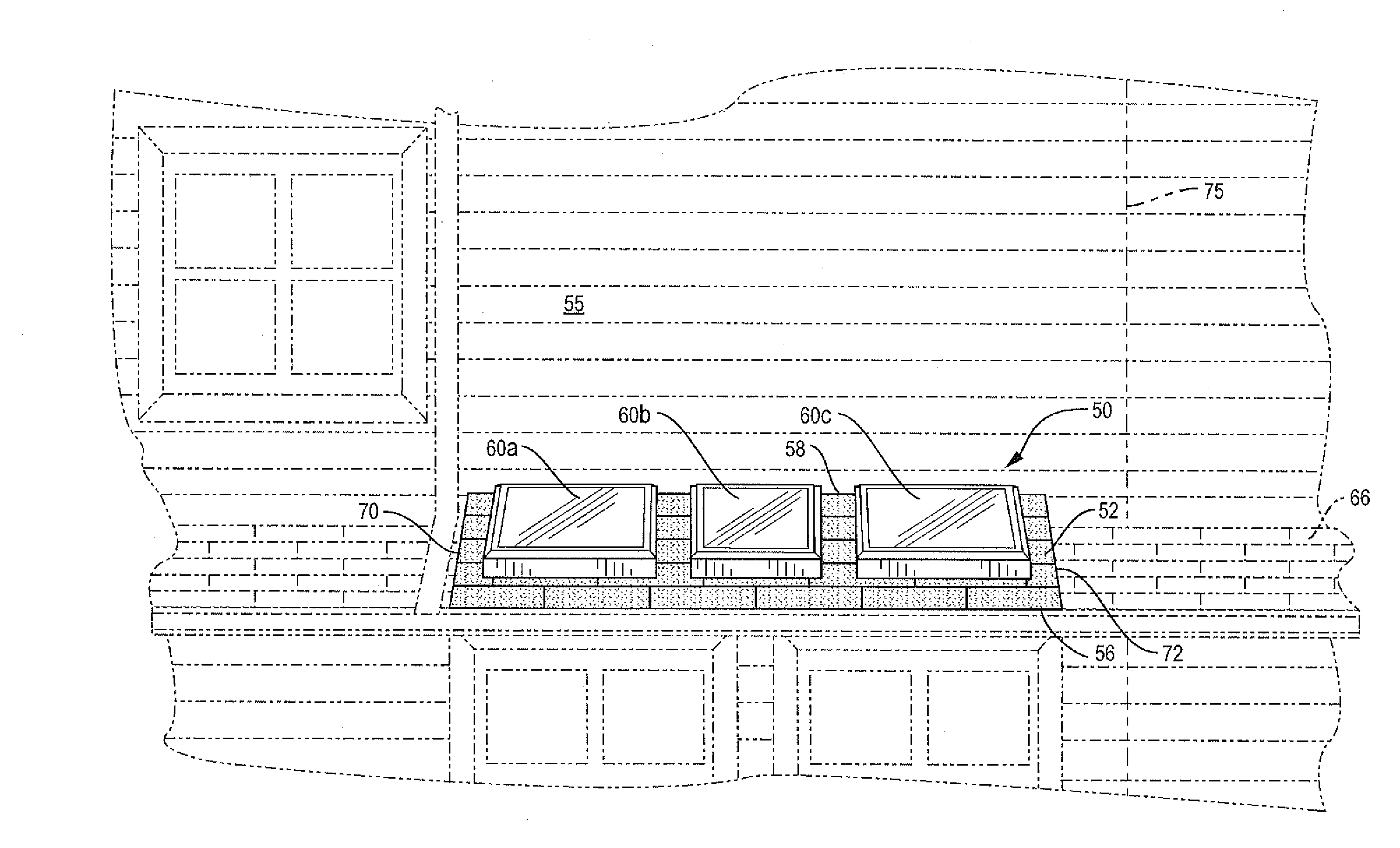

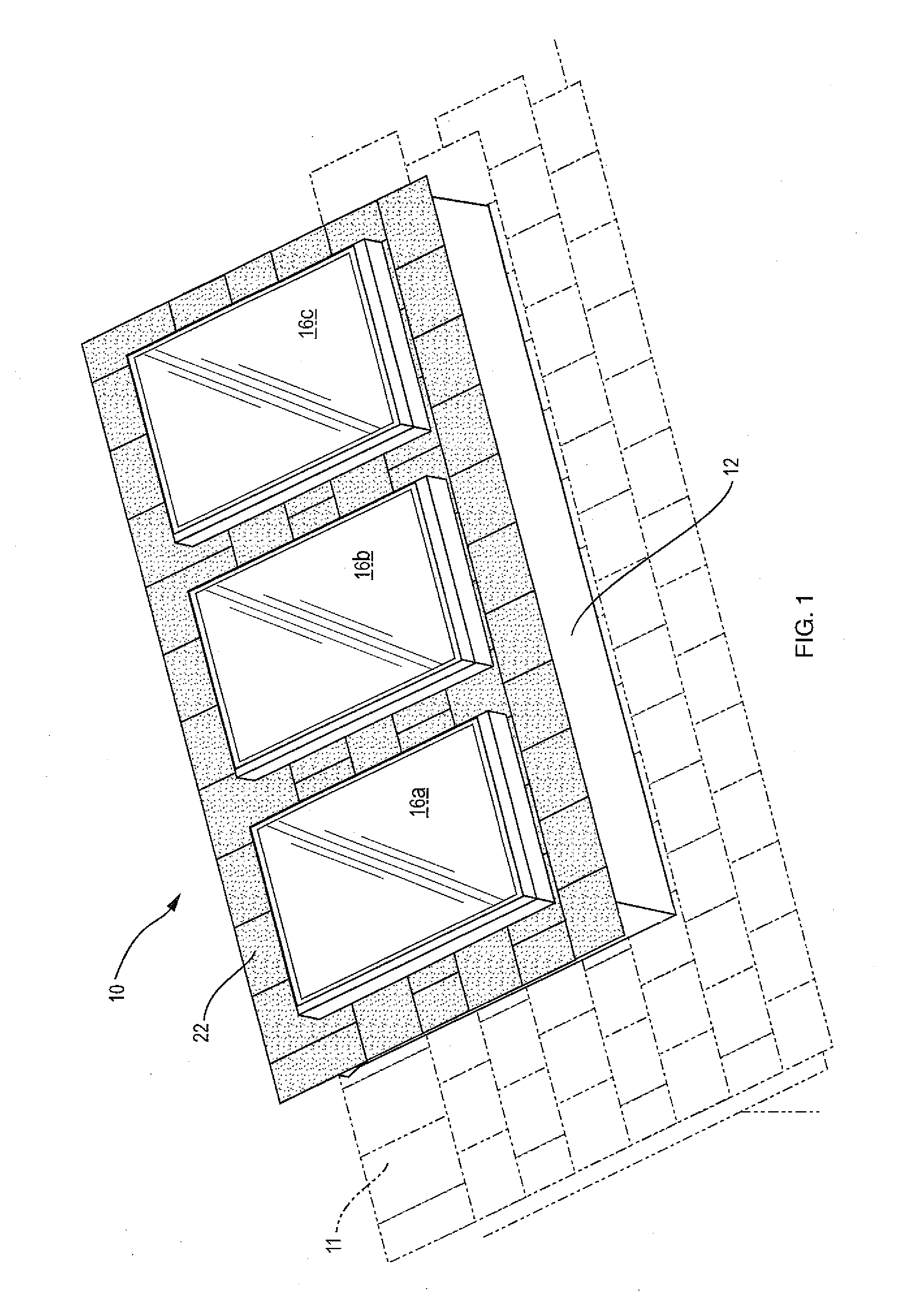

[0025]Referring to FIG. 1, a skylight roof assembly 10 having a raised roof 22 is shown installed on a roof 11 of a building. In some buildings an upper roof (not shown) may overhang above the skylight roof assembly 10. The method of making or constructing the skylight roof assembly 10 is accomplished away from the roof 11 on which it will be installed in an area generally protected from the weather. However, for a smaller roof assembly, it may be more efficient to construct the skylight roof assembly having a raised roof in place on the roof. The method is particularly useful for an existing roof 11 where it is highly desirable not to have an opening made in the roof until the skylight roof assembly 10 is constructed and ready to be installed on roof 11. The roof 11 may include an existing roof on a building, a plurality of existing skylights which may have become defective needing replacement, or a roof of a new building which may have plywood or boards on it.

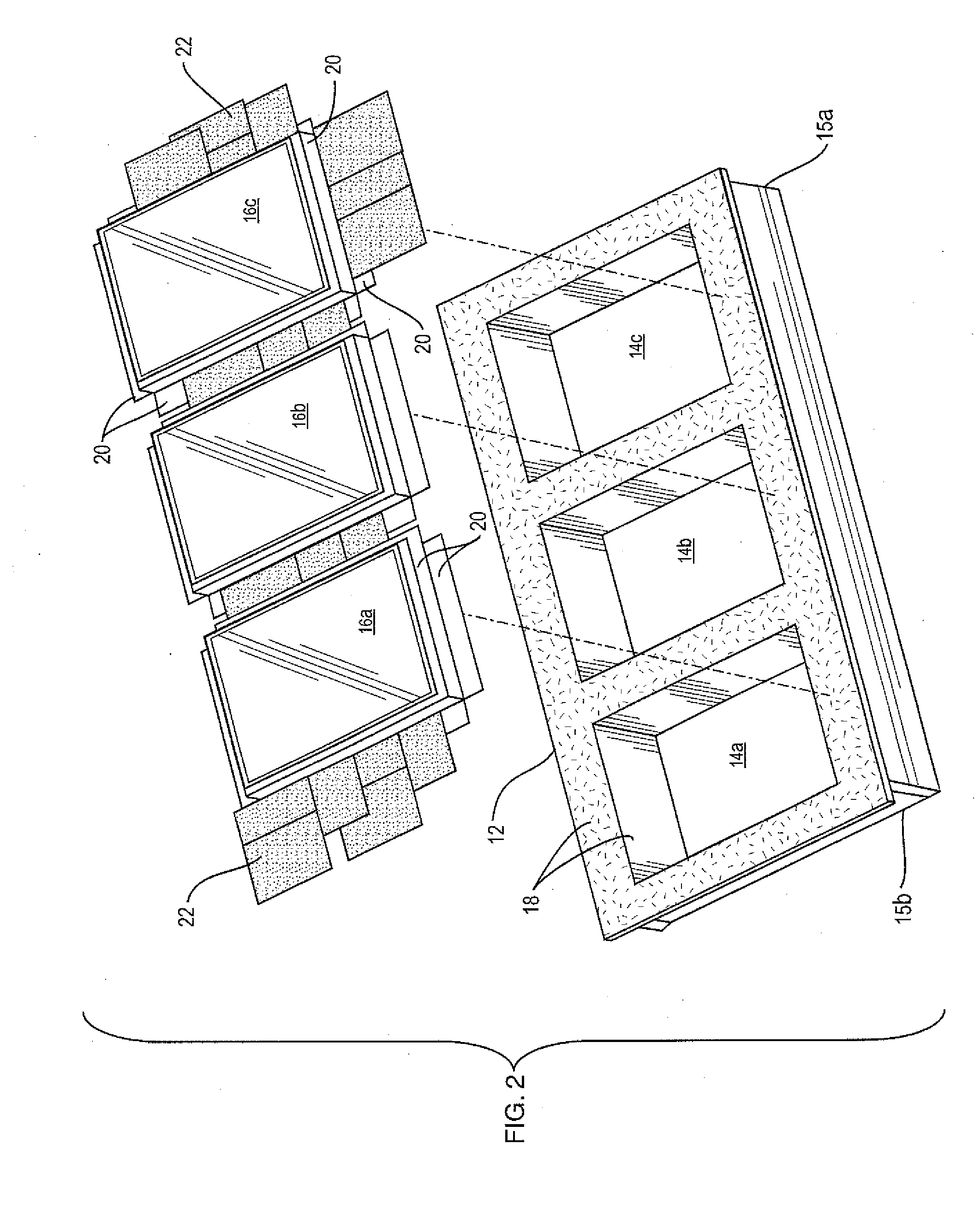

[0026]Referring to FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com