Boundary layer effect turbine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

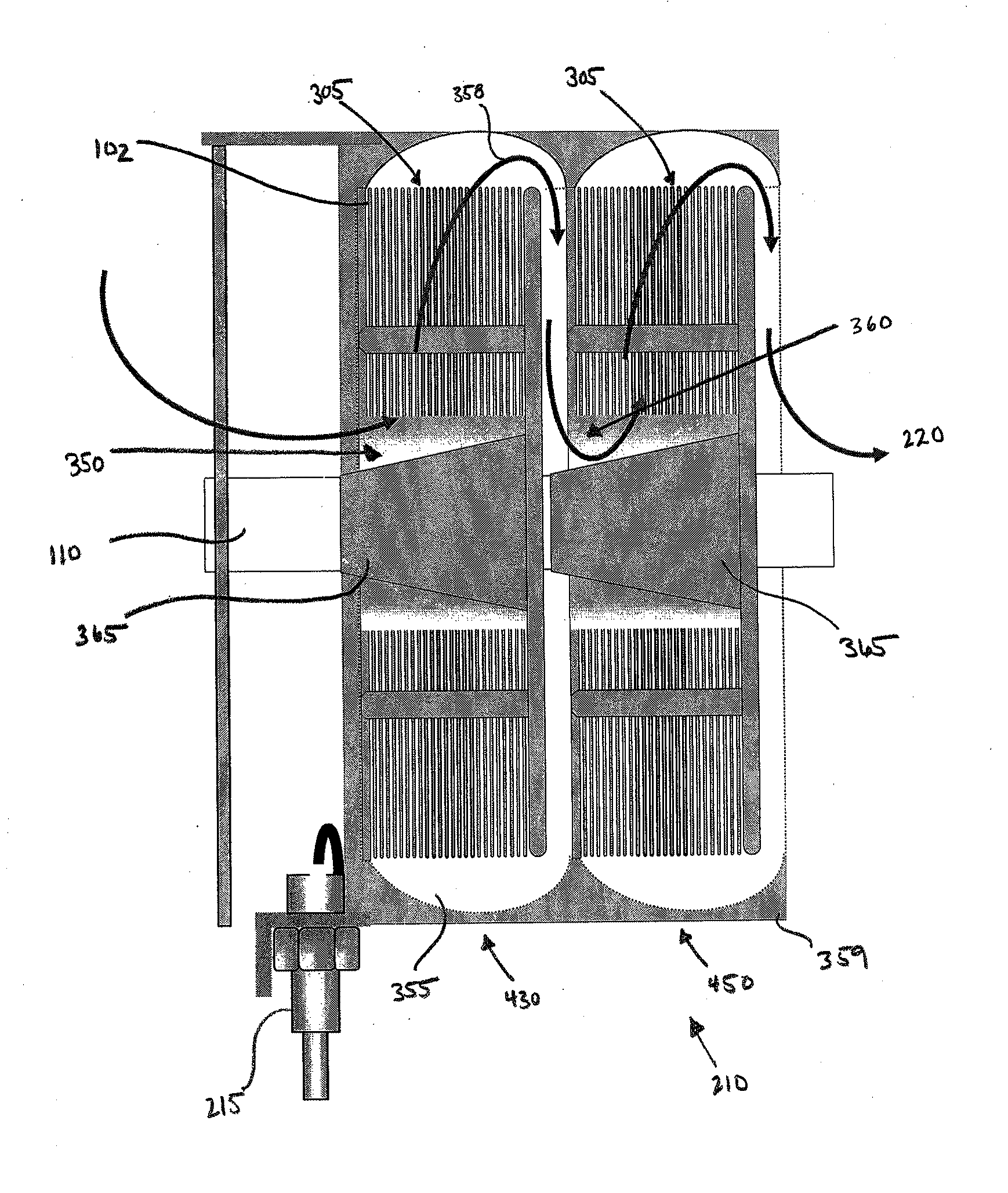

Method used

Image

Examples

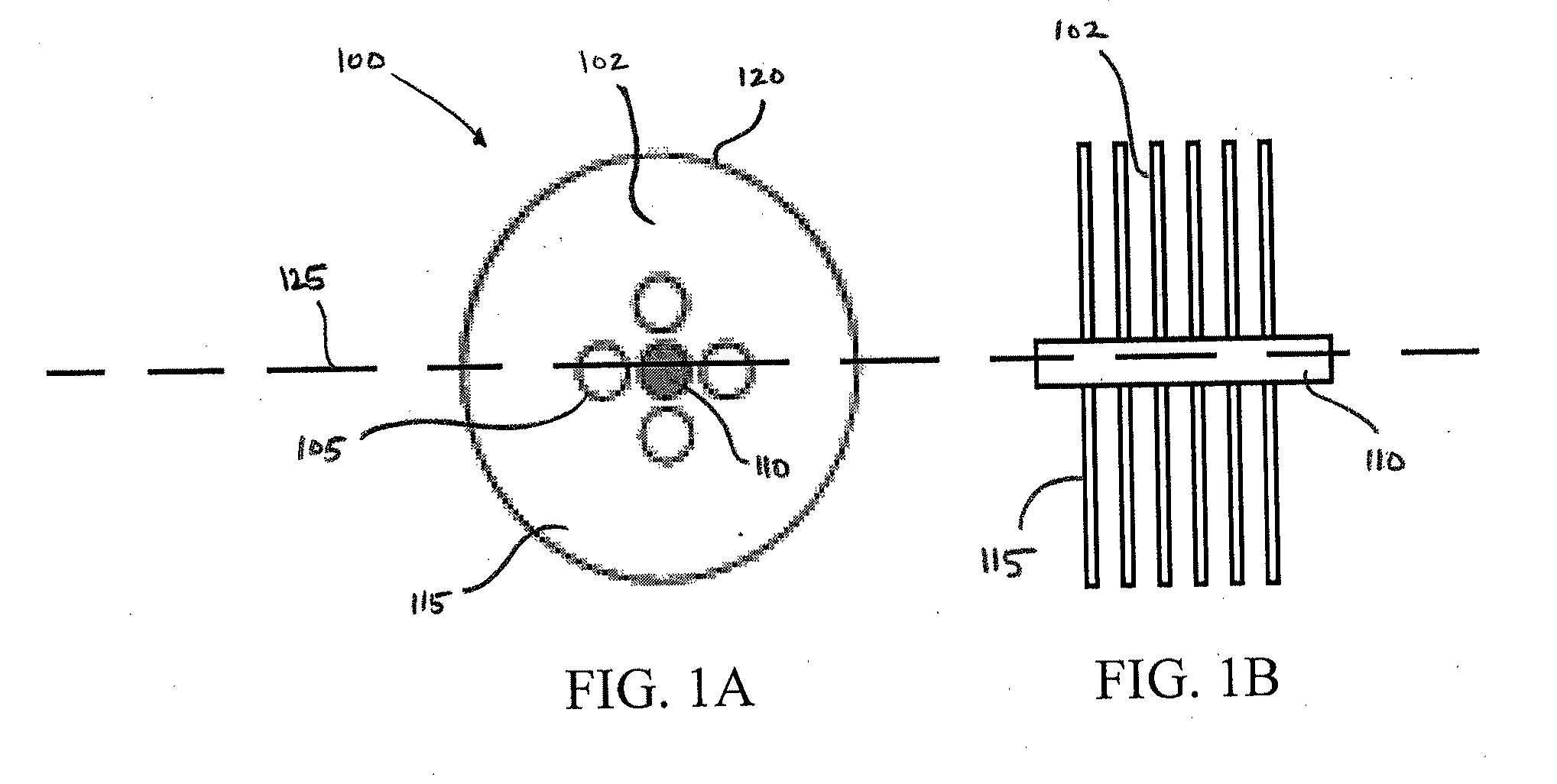

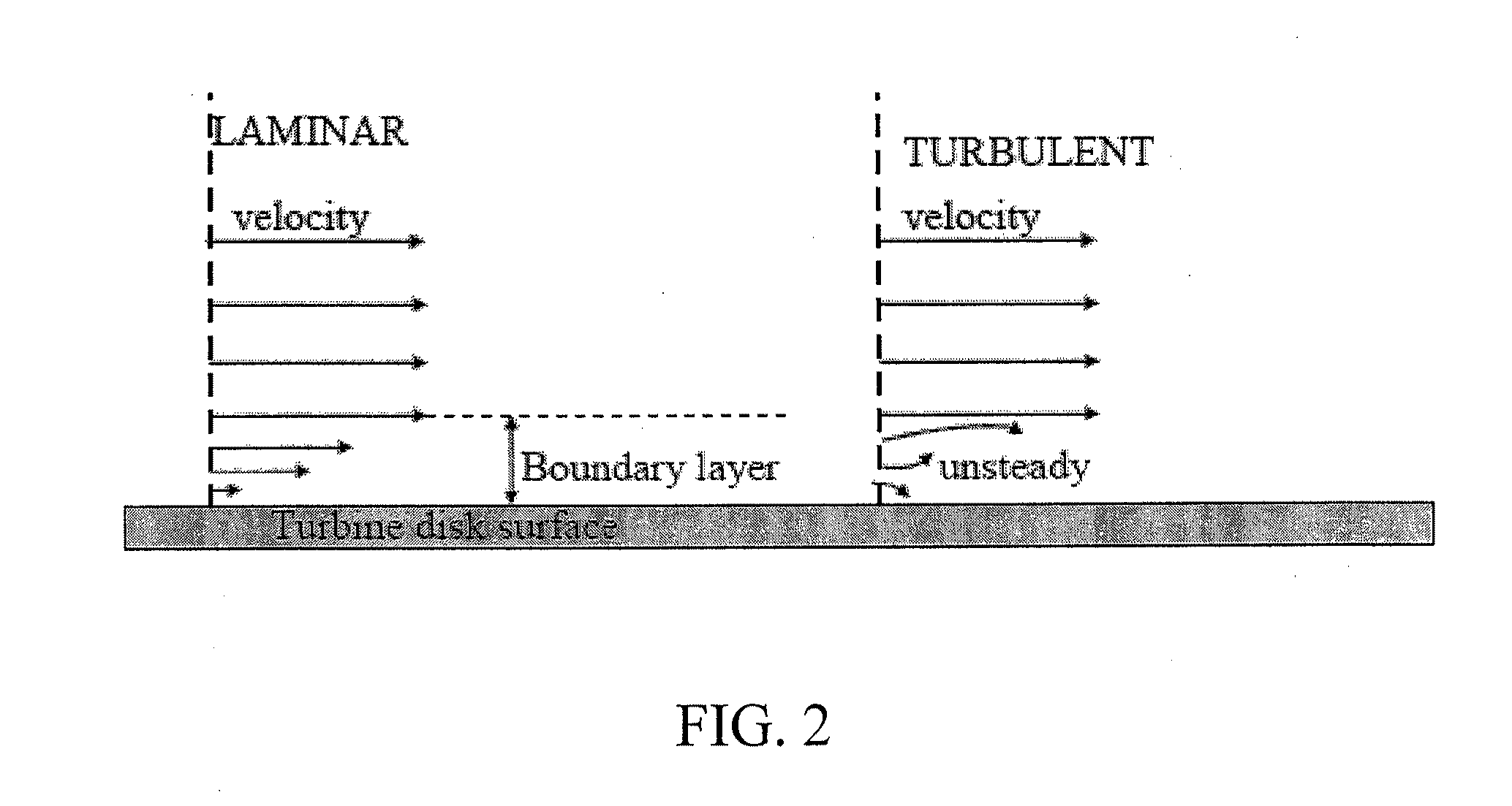

Embodiment Construction

[0096]The boundary layer effect turbine described herein has several advantages over the internal combustion engine and the blade turbine. The internal combustion engine is a complex system that has several moving parts that are arranged about a rotating crankshaft. While the internal combustion engine has been used for many purposes in many industries, the complex construction presents significant maintenance complications. Additionally, the reciprocating motion between various components of the internal combustion engine (e.g., the piston within the cylinder) results in the generation of heat caused by the friction between parts. The heat results in losses that decrease the efficiency of the internal combustion engine.

[0097]Similarly, the blade turbine is also plagued with complications arising from its principle of operation. Cavitation occurs as the operating fluid engages the blades moving at extremely high speeds. This damages the blades and presents different, but significant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com