Inkjet recording apparatus

a recording apparatus and inkjet technology, applied in the direction of printing, inking apparatus, etc., can solve the problems of inability to investigate the issue of using a manifold having a sufficient thickness in order to achieve a large-volume circulation of ink, and achieve the effect of accurate ink circulation, low pressure loss, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

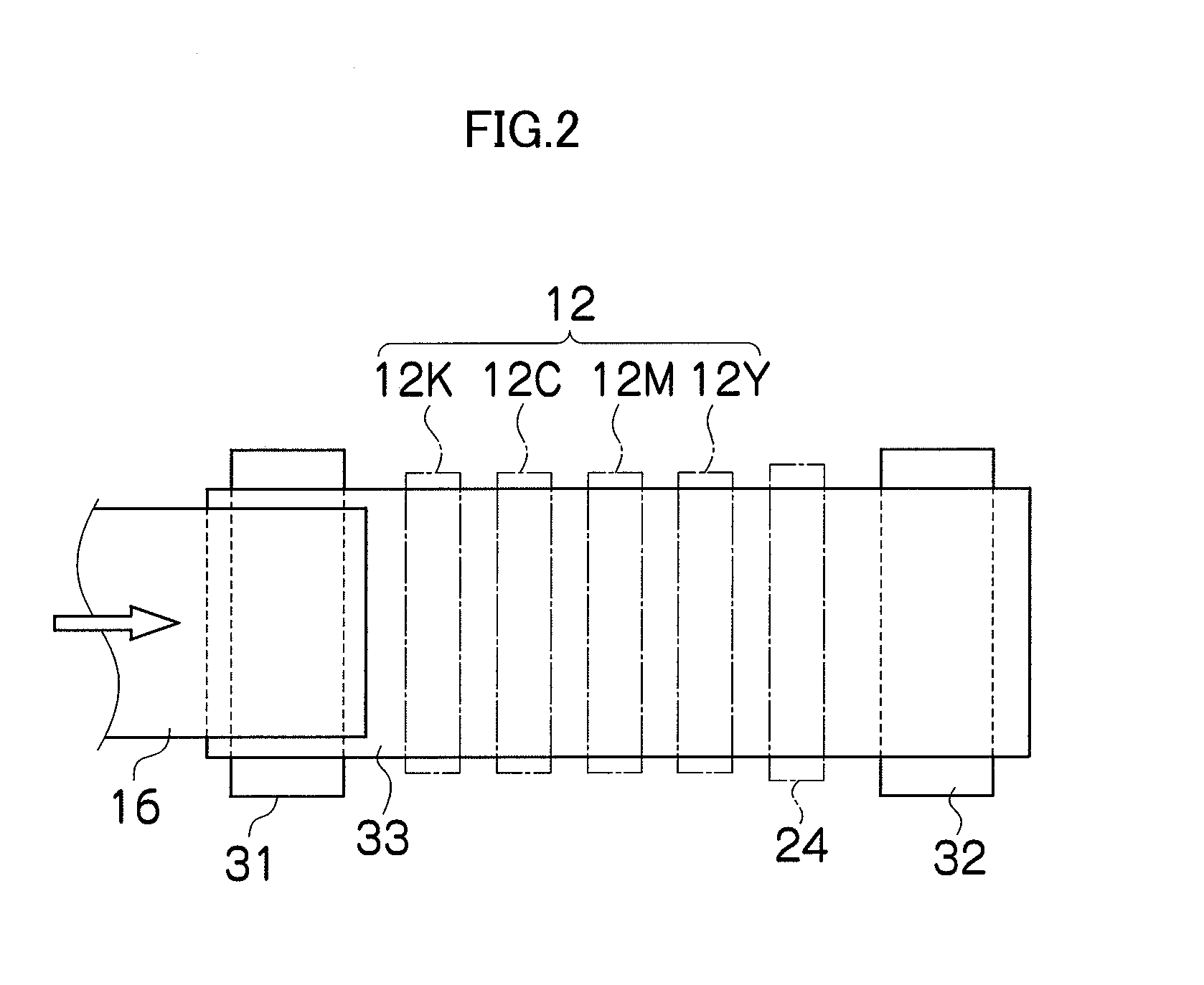

[0096]FIG. 6 is a schematic drawing showing the composition of the ink supply system according to a first embodiment of the present invention. In FIG. 6, in order to simplify the description, the ink supply system relating to one color only is depicted, and an inkjet recording apparatus of a plurality of colors is provided with a plurality of similar ink supply systems.

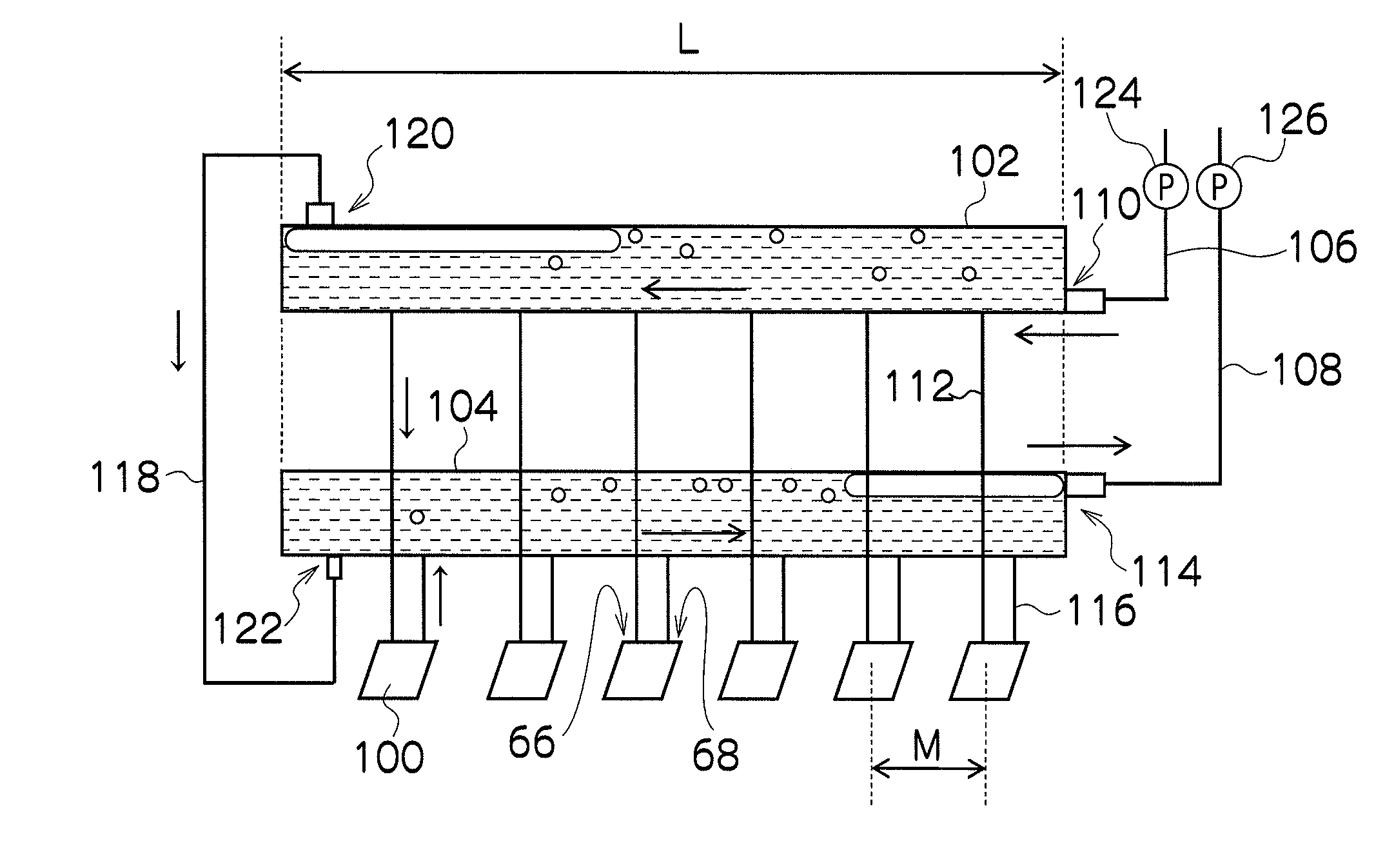

[0097]As shown in FIG. 6, the ink supply system of the inkjet recording apparatus 10 according to the present embodiment includes an ink supply manifold 102, which is a liquid chamber in which the ink supplied from the ink tank (not shown) to the respective head modules 100 is temporarily stored, and an ink collection manifold 104, which is a liquid chamber in which the ink collected from the head modules 100 to the ink tank is temporarily stored.

[0098]Each of the ink supply manifold 102 and the ink collection manifold 104 has a long thin shape having the lengthwise direction thereof along the direction in which the h...

second embodiment

[0116]FIG. 7 is a schematic drawing showing the composition of the ink supply system according to a second embodiment of the present invention. In FIG. 7, elements which are the same as or similar to those in FIG. 6 are denoted with the same reference numerals and description thereof is omitted here.

[0117]In the second embodiment, the bubble expulsion bypass flow channel 118 is provided with a valve (opening / closing valve) 130 as shown in FIG. 7. The opening and closing operation of the valve 130 is controlled by the system controller 72 shown in FIG. 5.

[0118]When performing the expulsion of bubbles, the system controller 72 implements control to open the valve 130, set the ink supply manifold 102 and the ink collection manifold 104 to a connected state through the bubble expulsion bypass flow channel 118, and move the bubbles in the ink supply manifold 102 to the ink collection manifold 104 through the bubble expulsion bypass flow channel 118. On the other hand, at other times (whe...

third embodiment

[0120]FIG. 8 is a schematic drawing showing the composition of the ink supply system according to a third embodiment of the present invention. In FIG. 8, elements which are the same as or similar to those in FIG. 6 or 7 are denoted with the same reference numerals and description thereof is omitted here.

[0121]If the ink supply manifold 102 and the ink collection manifold 104 are composed to have thick dimensions as in the respective embodiments described above, the ink flow rate in the manifolds becomes slow, the ink temperature varies due to exchange of heat with the surrounding air, and there is a concern that a difference will occur in the ink temperature between the head modules 100.

[0122]Hence, in the third embodiment, a circulation bypass flow channel 132, which is separate from the bubble expulsion bypass flow channel 118, is arranged between the ink supply manifold 102 and the ink collection manifold 104 as shown in FIG. 8. Thus, it is possible to circulate the ink directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com