Process and apparatus for electroplating substrates

a technology of electroplating substrates and electrochemical plating equipment, which is applied in the direction of electrolysis components, vacuum evaporation coatings, coatings, etc., can solve the problems of affecting the speed of the movement of objects, the length of the electrochemical plating apparatus for a given speed of movement must be very large, and the process produces no significant increase in throughput. , to achieve the effect of increasing the throughput of the substrate through the coating apparatus and the speed of the coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

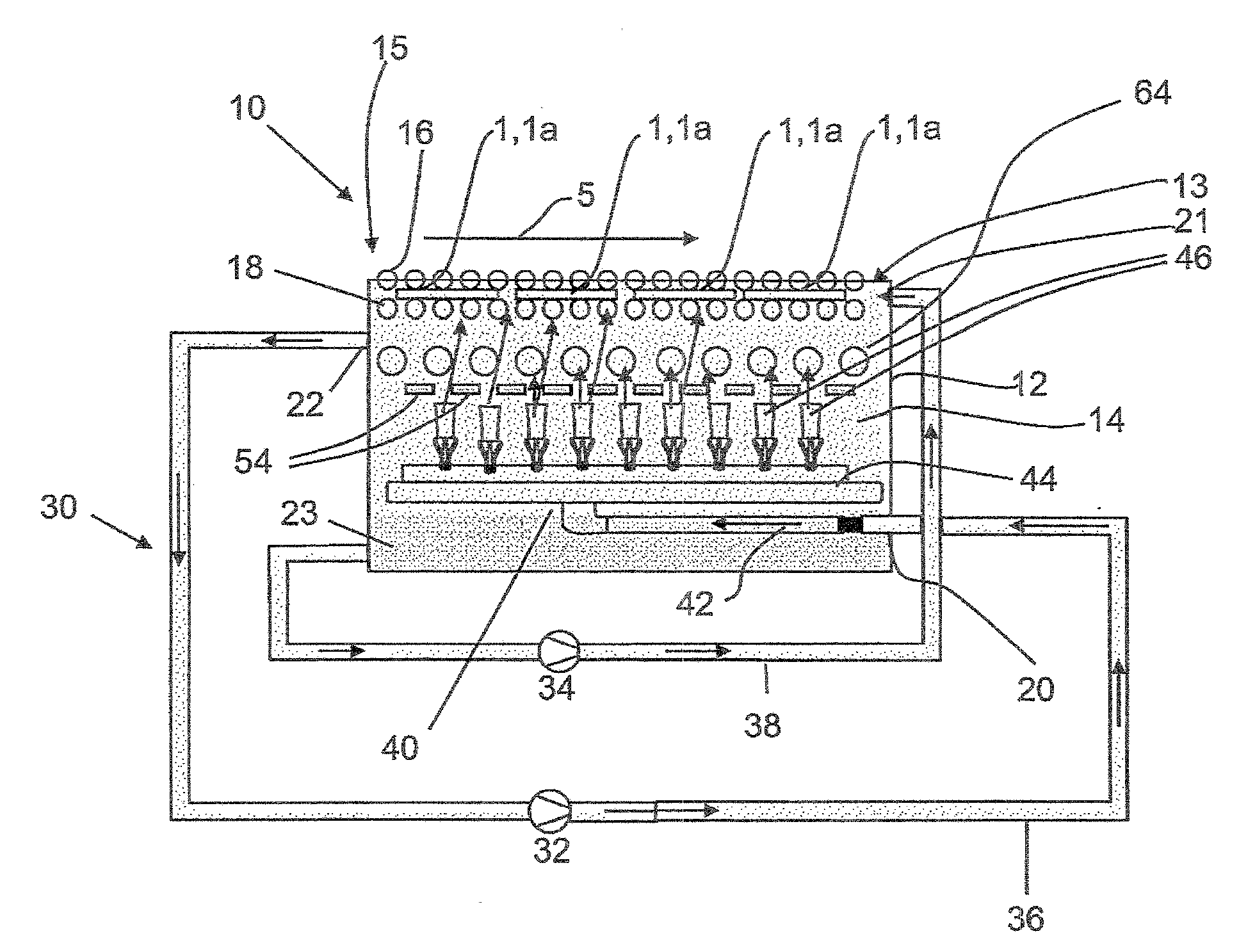

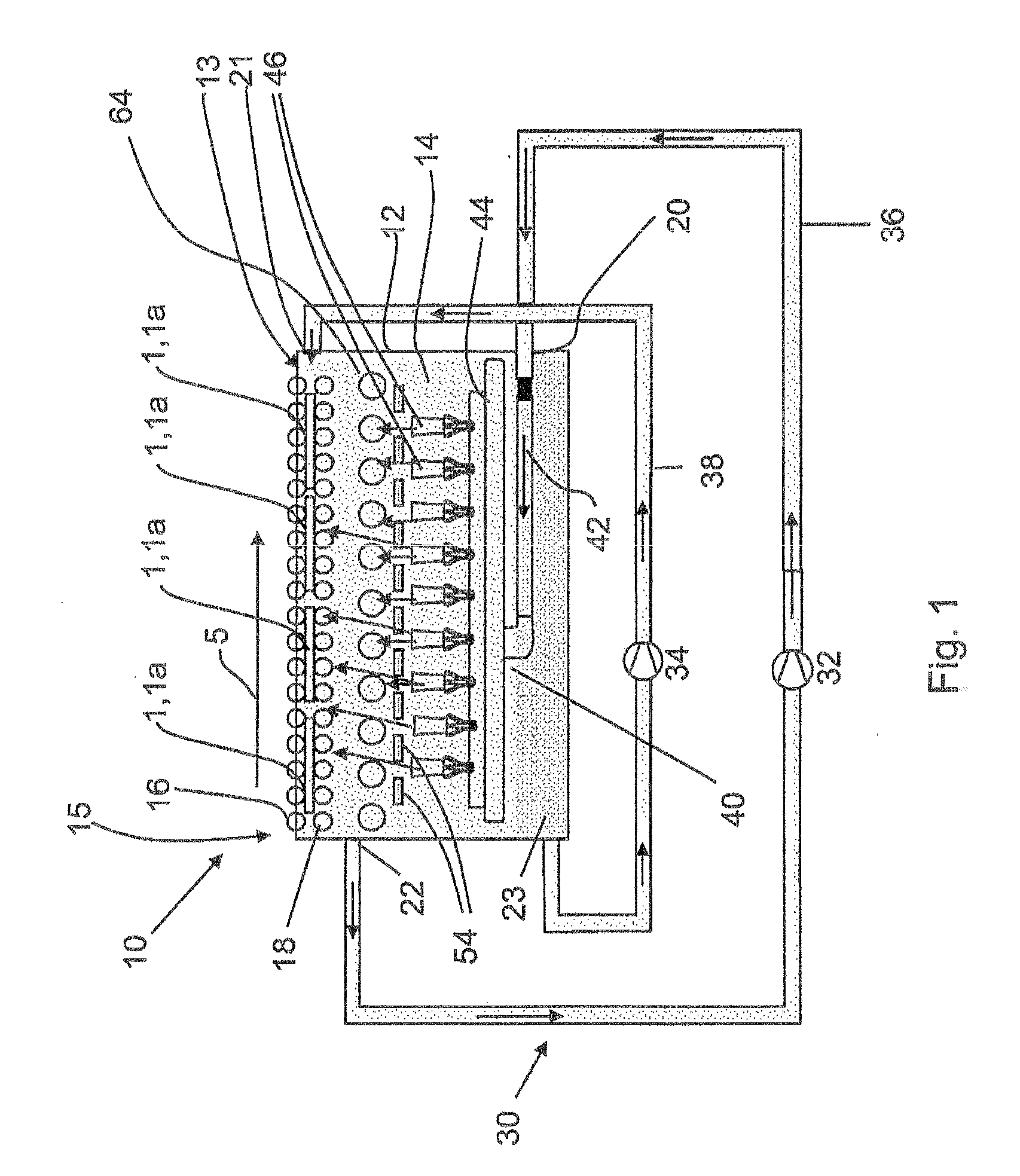

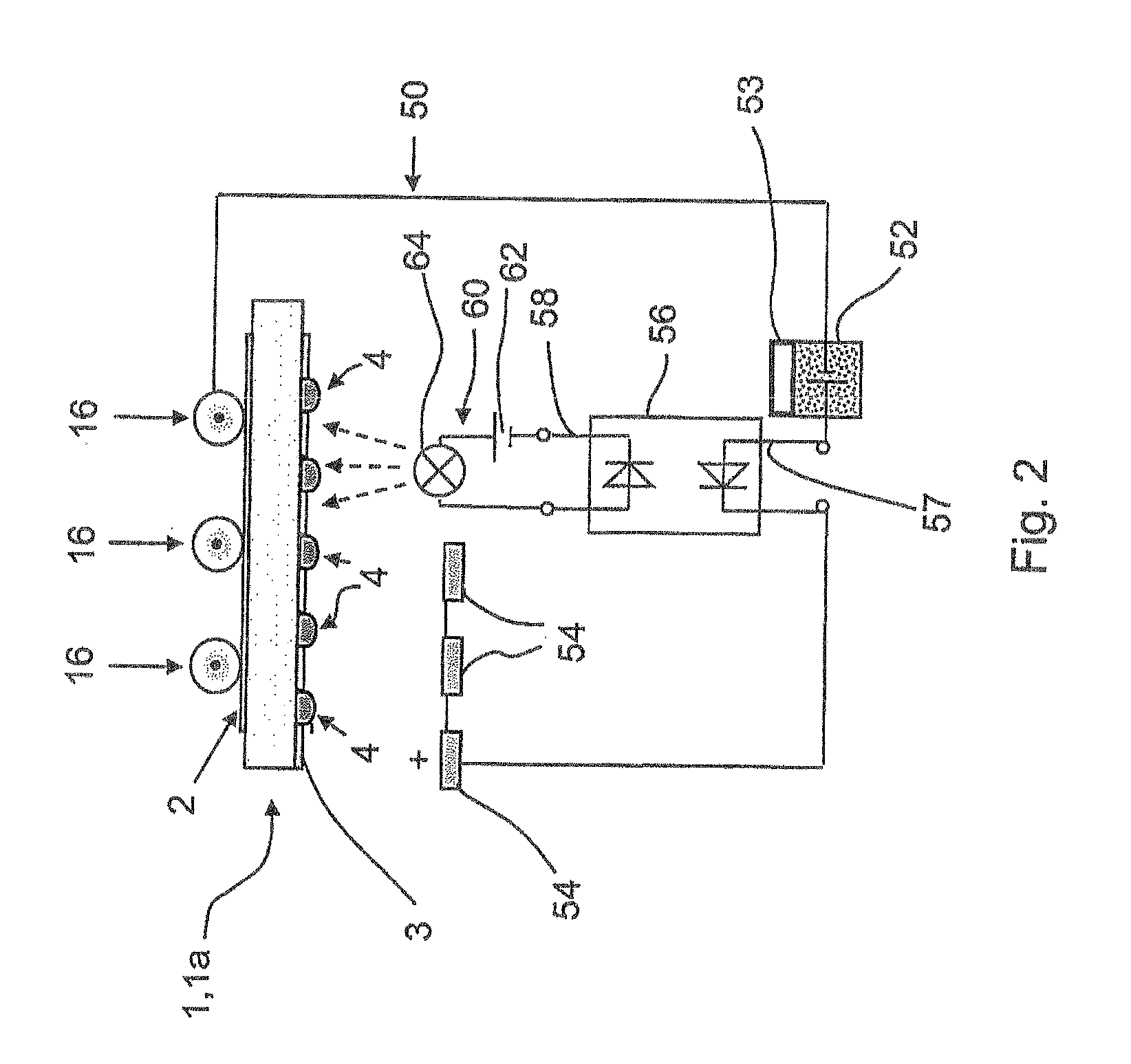

[0051]An apparatus 10 for coating substrates 1 is illustrated in FIG. 1. Solar cells 1a are used as substrates in the present example. The apparatus 10 includes a coating tank 12, which comprises a coating bath 13, which contains an electrolytic coating liquid 14.

[0052]A conveying device 15, which comprises upper conveying rollers 16 and lower conveying rollers 18, is provided in the upper part of the coating tank 12. The solar cells 1a are held between the upper and lower conveying rollers 16, 18 and conveyed in the direction of the arrow 5. Since the coating tank 12 is filled with the coating liquid 14, the solar cells 1a are completely within the coating bath 13.

[0053]A circulation device 30 for producing a flow in the coating bath 13, which has a first liquid conductor 36, is provided. The coating tank 12 has a first outlet 22 below the conveying device 15, to which the first liquid conductor 36 is connected. The coating liquid 14 is pumped from the coating tank 12 via the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com