Shell-and-Tube Heat Exchanger

a heat exchanger and shell technology, applied in the direction of tubular elements, lighting and heating apparatus, stationary conduit assemblies, etc., can solve the problem of not being able to remove any more, and achieve the effect of efficient cleaning and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

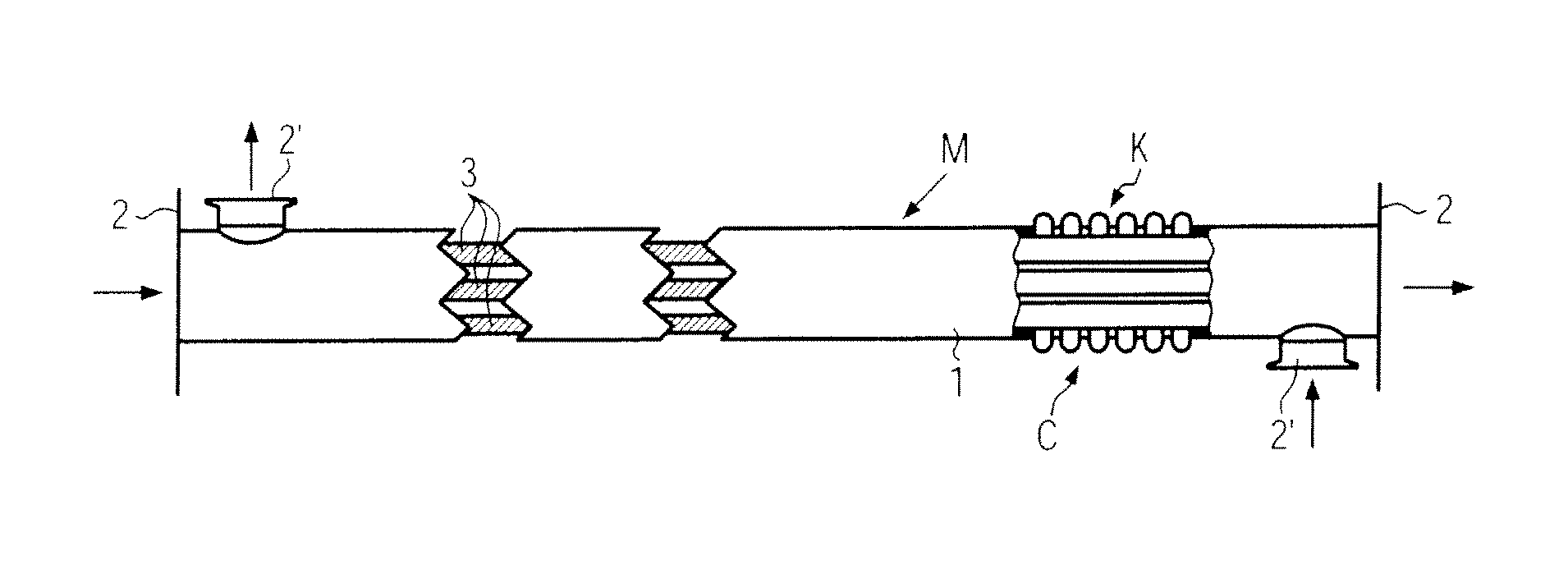

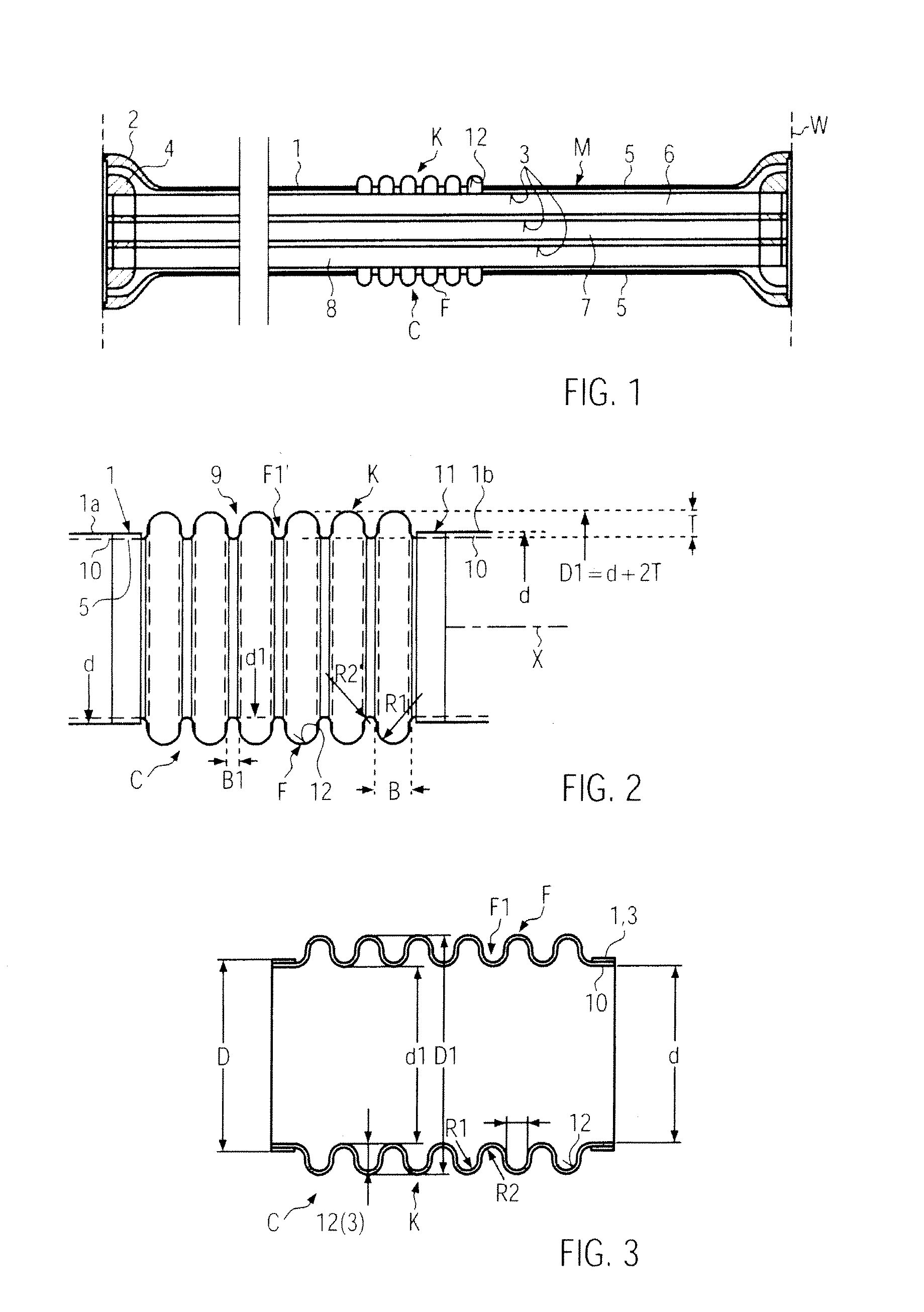

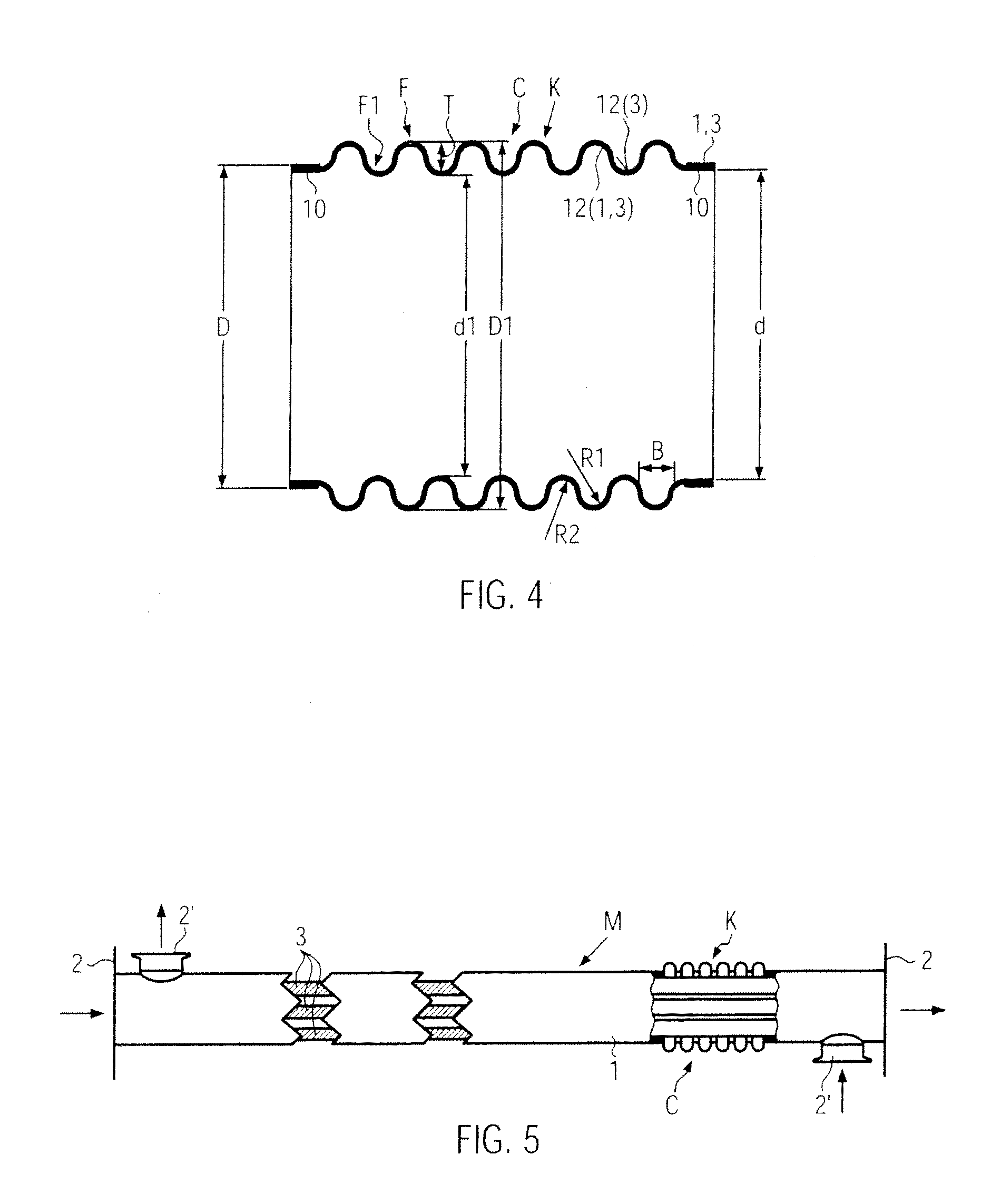

[0022]Each of FIGS. 1 and 5 illustrates an individual module M of a shell-and-tube heat exchanger W shown in broken line, as is e.g. used in the bottling or filling industry for liquid food products (e.g. water, juices, milk) for a product / product flow guidance in the heat treatment (heating or cooling) of a food product. In the shell-and-tube heat exchanger W it is possible to install a plurality of modules so as to obtain flow paths for the product that are as long as possible. Module M may here have a length of e.g. 3.0 m, 6.0 m, or even more.

[0023]In FIG. 1 the module M comprises a casing tube 1, e.g. of stainless steel, which comprises end-sided fastening flanges 2 for installation in the shell-and-tube heat exchanger W. In the casing tube 1 at least one inner tube 3 is provided that extends substantially axially parallel with respect to the casing tube 1 between fastening flanges 4. In the embodiment in FIG. 1, several inner tubes 3 are provided that are combined to form a tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com