Entrained-flow gasification of biomass as slurry

a gasification method and biomass technology, applied in the direction of gasifier mechanical details, combustible gas production, waste based fuel, etc., can solve the problems of uneconomic method and unfavorable transmission method, and achieve the effect of reducing energy expenditur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

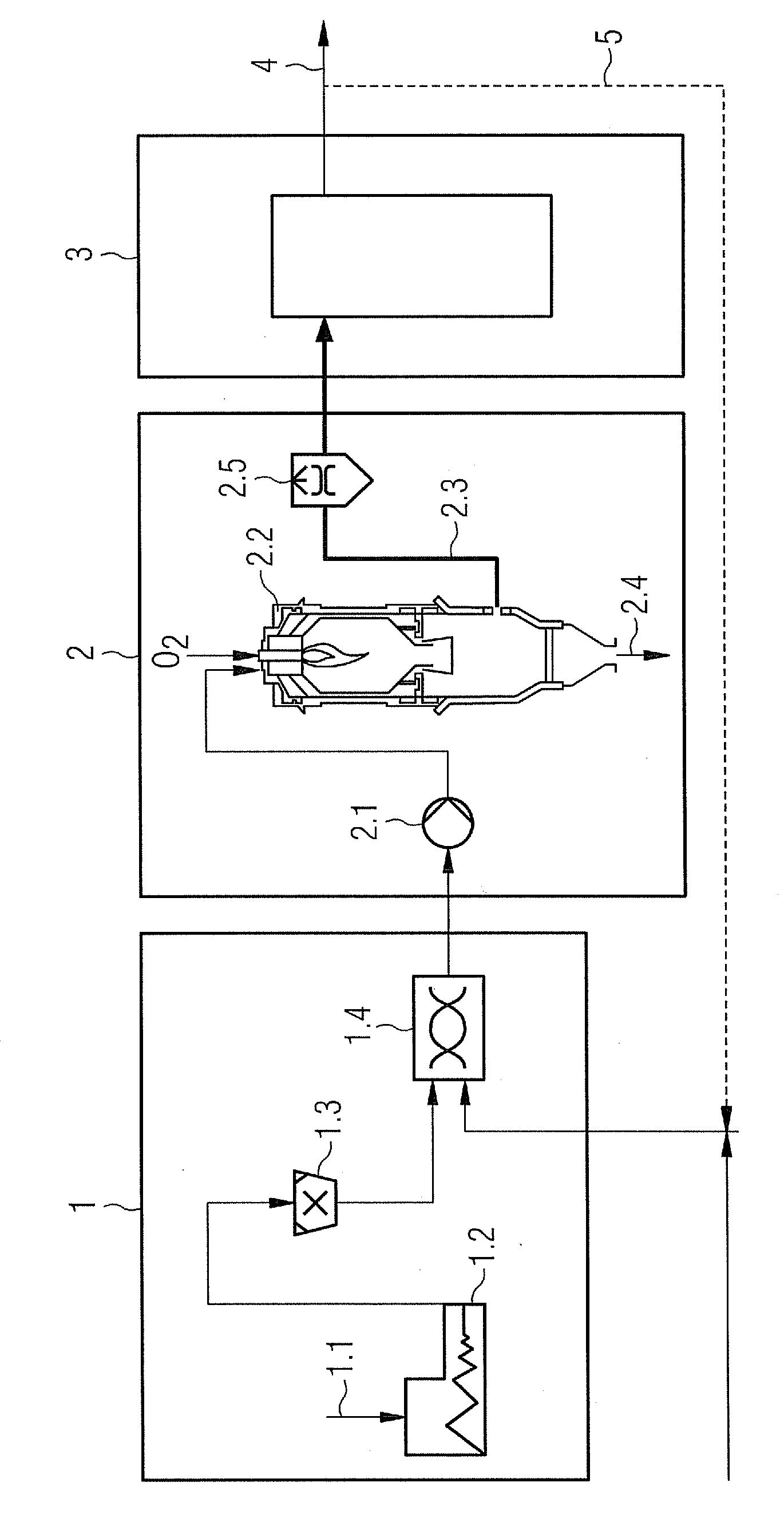

[0012]In a first stage 1, which may be described as “biomass torrefaction”, biomass 1.1, such as e.g. wood, straw or miscanthus, is torrefied in a torrefaction apparatus 1.2. The torrefied biomass is fed to a mill 1.3, where it is ground into particles that are suitable for the following slurry generation. The particles are supplied via a first inlet to a mixing apparatus 1.4 to which a liquid medium such as water, oils, heavy oil, bio-oil, glycerin, methanol, liquid CO2, paraffin, tar etc. is supplied via a second inlet. The biomass is mixed with the liquid medium in the mixing apparatus to produce a slurry.

[0013]The slurry is fed to a second stage 2, which may be described by the term “gasification”, where it is supplied by means of a slurry pump 2.1 to an entrained-flow gasification reactor 2.2 together with an oxidizing agent O2 containing free oxygen. A partial oxidation of the supplied slurry takes place in the entrained-flow gasification reactor in a flame reaction under high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| flow rate | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com