Paper Tube Packaging with Coated Interior

a paper tube and interior technology, applied in the field of containers, can solve the problems of significant cost, indistinguishable pla and similar plastics from normal plastics, and very slow decomposition rate, so as to prevent unintentional and undesired removal of the cap and prevent tampering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

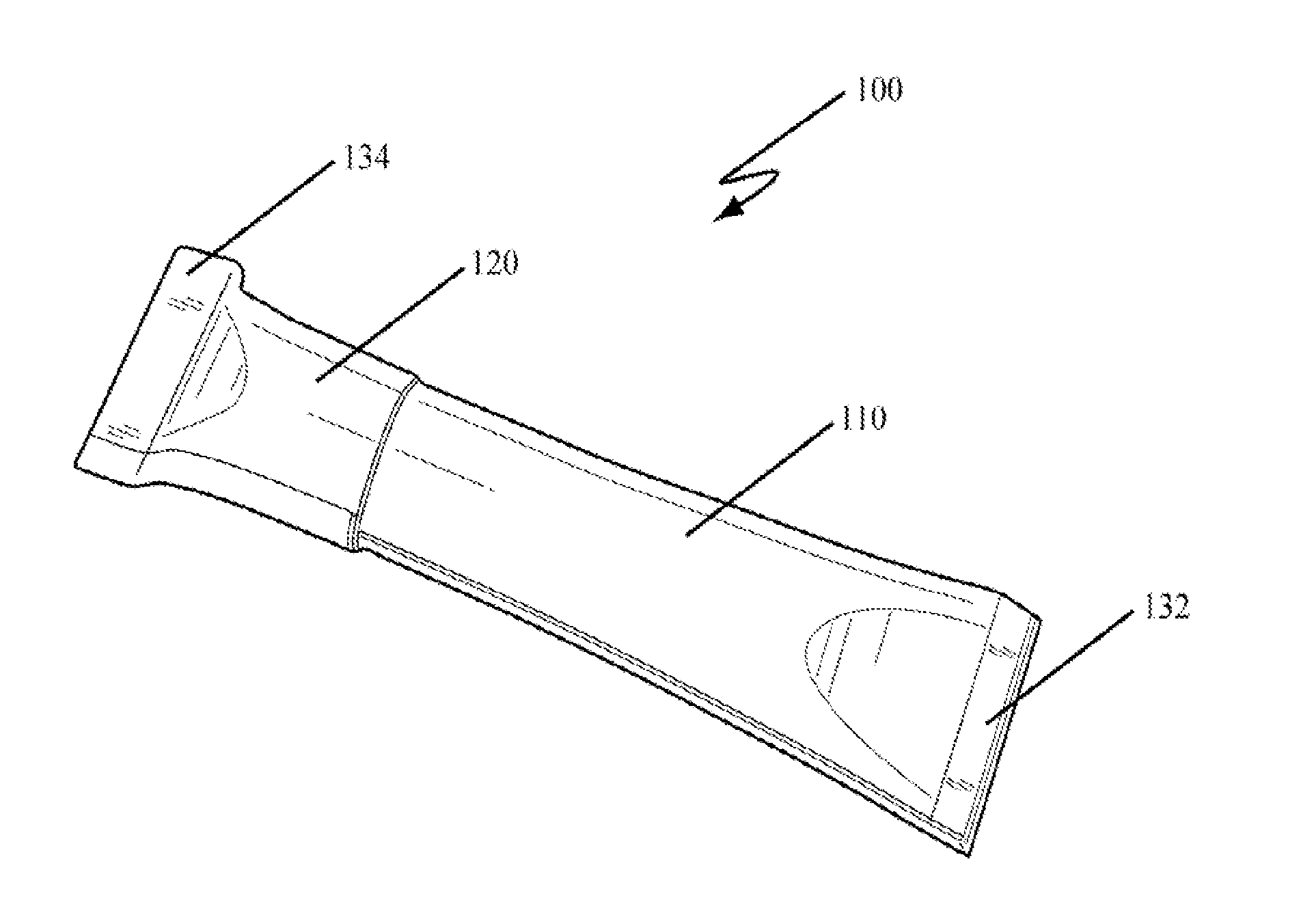

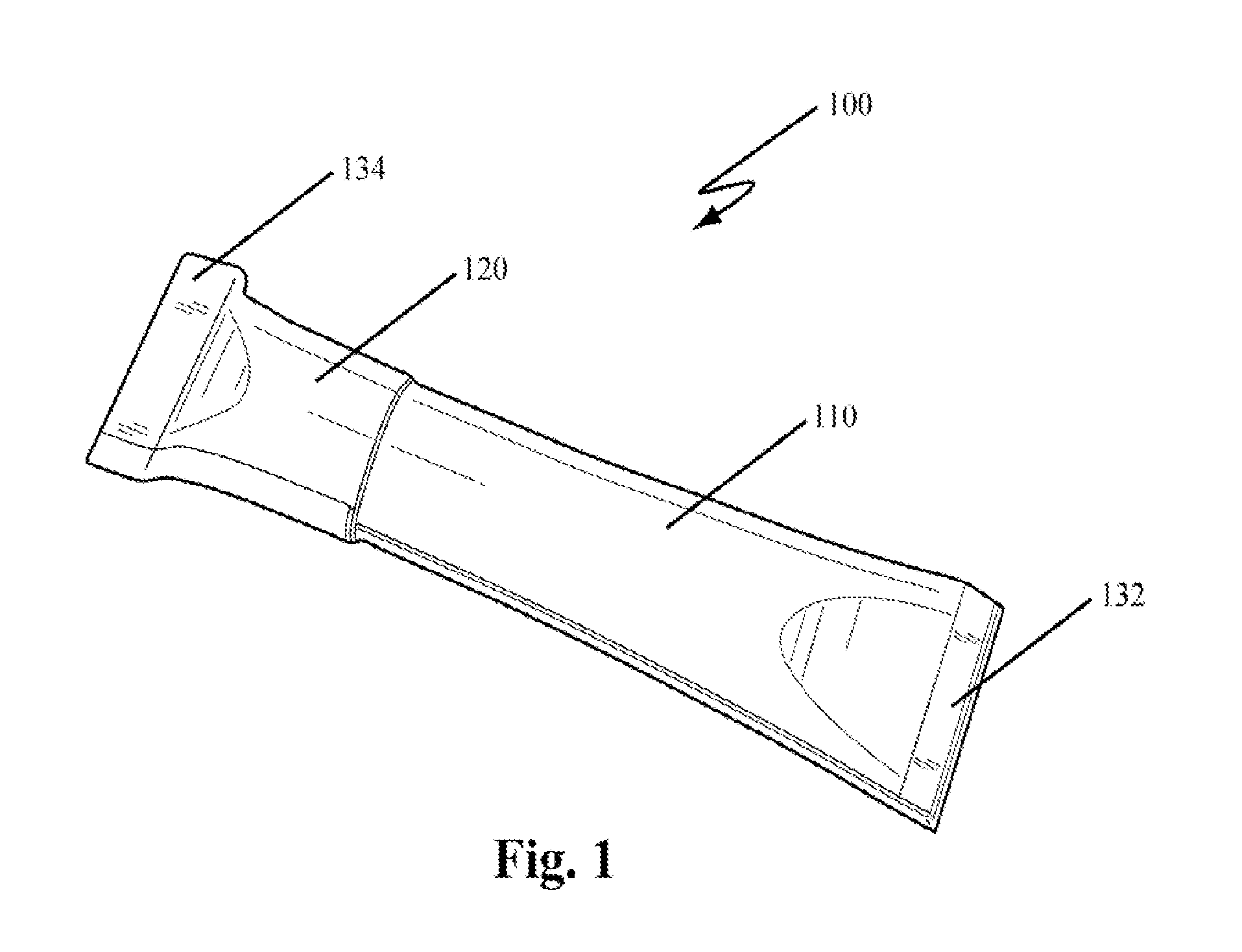

[0041]FIG. 1 generally depicts tube 100 of the present invention, comprising a tubular body 110 and a tubular cap 120 mated with body 110. As shown in FIG. 1, body 110 and cap 120 have tapered sealed ends 132 and 134, respectively.

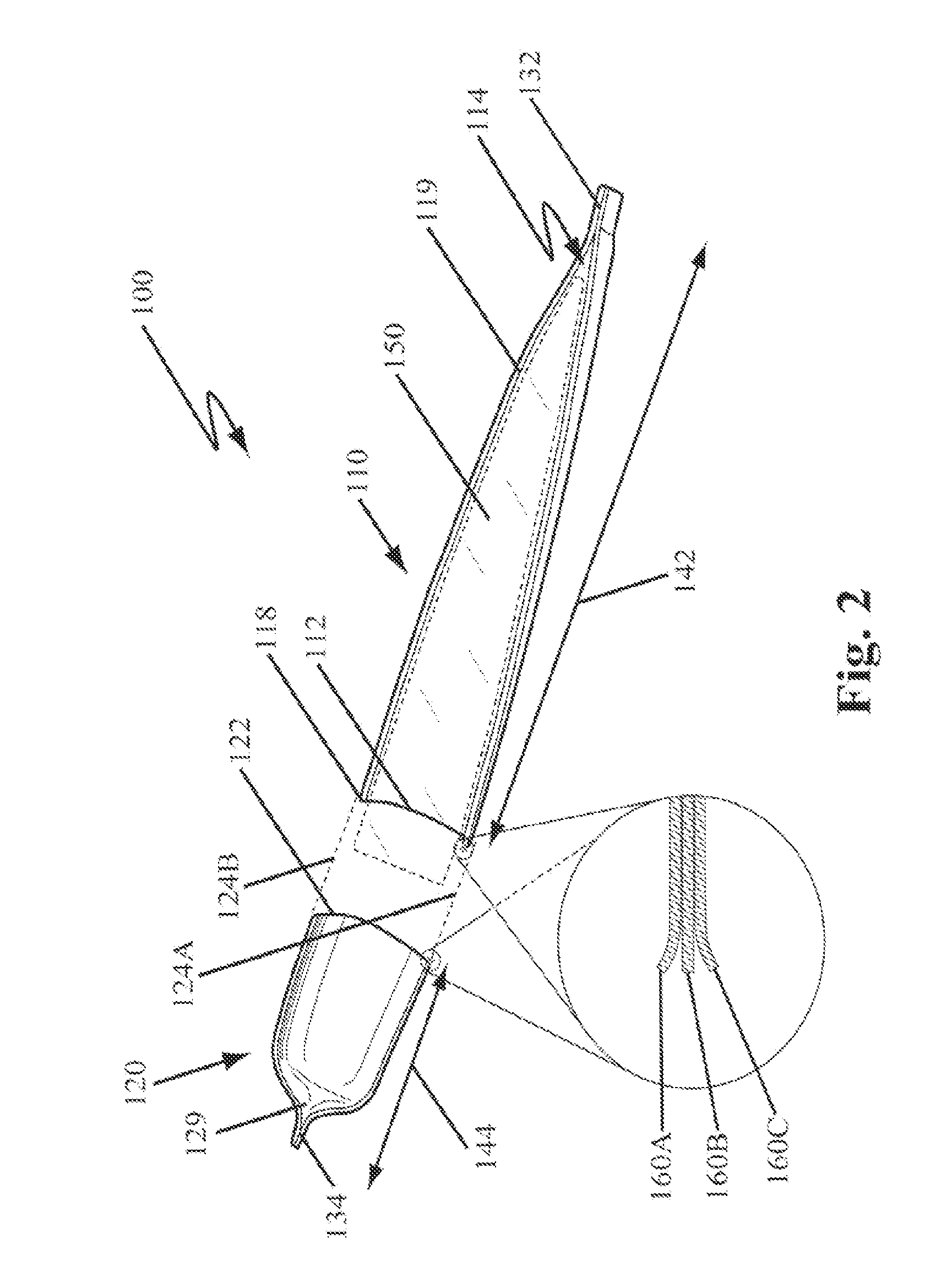

[0042]FIG. 2 is a cross sectional view of tube 100 of FIG. 1 having tubular body 110 and cap 120. As shown in FIG. 2, body 110 has an open end 112, a tapered sealed end 132, and a lumen 114 defined by the walls of body 110 containing a semi-solid composition 150. Cap 120 is depicted as having an open end 122 and a tapered sealed end 134, and a lumen defined by the walls of the cap 120. The open end 122 of cap 120 is sized and dimensioned to slidably engage an exterior surface 118 of the open end 112 of the body 110 (shown by dotted lines 124A and 124B). It is contemplated that an interior surface 119 of body 110 and an interior surface 129 of cap 120 have a substantially impermeable coating (not shown) to the semi-solid composition 150.

[0043]In a preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com