Automatic dispenser

a dispenser and automatic technology, applied in the field of automatic dispensers, can solve the problems of affecting the affecting the safety of the ejection device, and the delivery of articles, so as to achieve the effect of simple detection of the movement simple operation of the ejection device, and accurate and reliable determination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

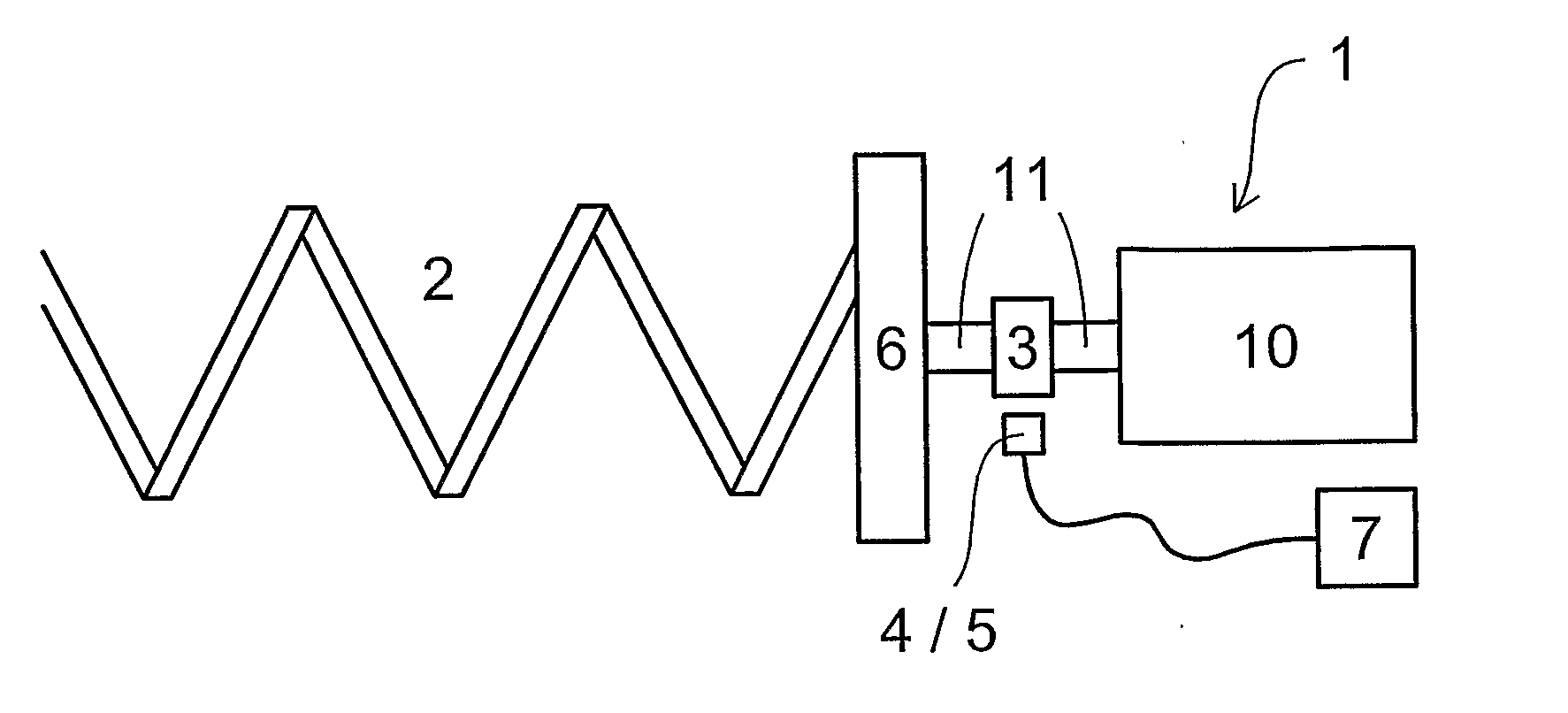

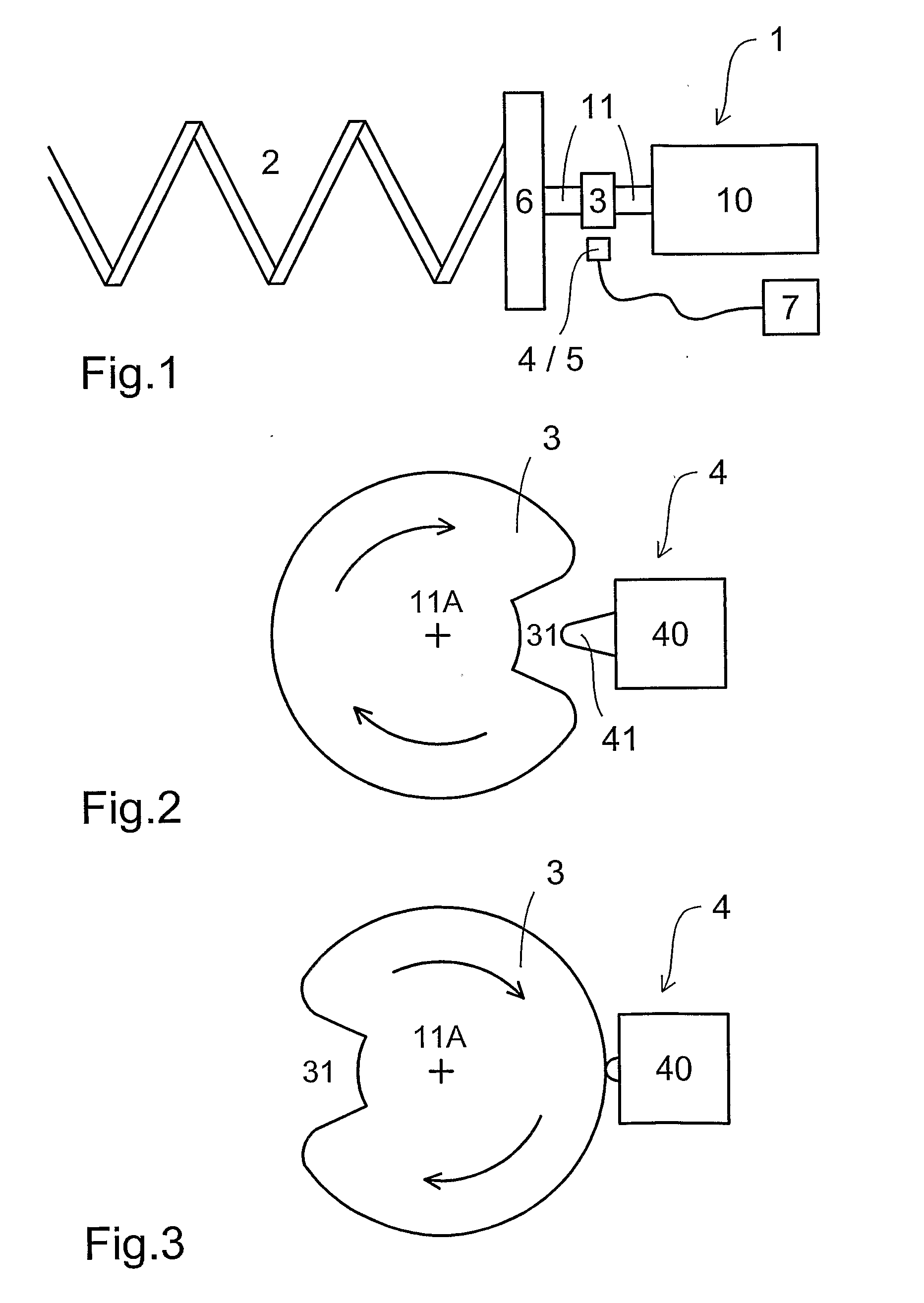

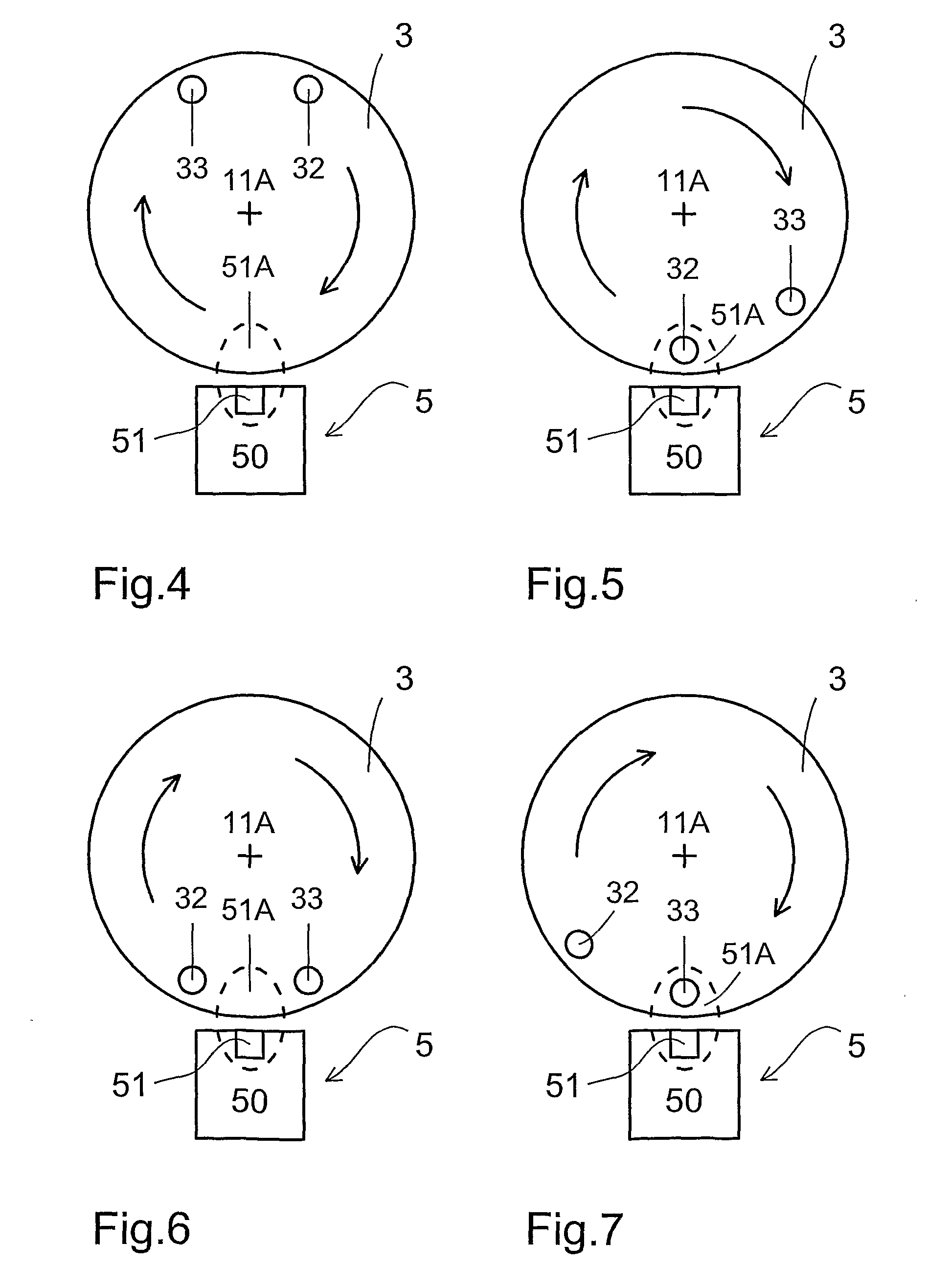

[0036]The present invention will now be described with reference to FIG. 1 as well as to FIG. 4, FIG. 5, FIG. 6, FIG. 7 and FIG. 8.

[0037]The automatic dispenser according to the present invention is equipped with an ejection assembly; said assembly comprises at least:

[0038]a geared motor (1 in FIG. 1),

[0039]an ejection device (2 in FIG. 1) fitted either directly or indirectly to the output shaft (11 in FIG. 1) of the geared motor (1 in FIG. 1),

[0040]detection means (3 and 5 combined together in FIG. 1) configured to detect the movement of the ejection device (2 in FIG. 1); the detection means comprise:

[0041]at least one magnet (32 and / or 33 in FIG. 4, FIG. 5, FIG. 6 and FIG. 7) associated with the output shaft (11 in FIG. 1) of the geared motor (1 in FIG. 1),

[0042]at least one magnetic sensor (5 in FIG. 1) positioned in a manner such as to detect when said at least one magnet (32 and / or 33 in FIG. 4, FIG. 5, FIG. 6 and FIG. 7) passes through a predetermined region (51A in FIG. 1),

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com