Decarboxylation cell for production of coupled radical products

a decarboxylation cell and product technology, applied in the direction of electrolysis organic production, bio-feedstock, electrolysis components, etc., can solve the problems of high cost of hydrocarbon production and high cost of decarboxylation process, and achieve the effect of preventing the mixing of anolyte and catholy

Inactive Publication Date: 2011-02-03

CERAMTEC

View PDF27 Cites 64 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

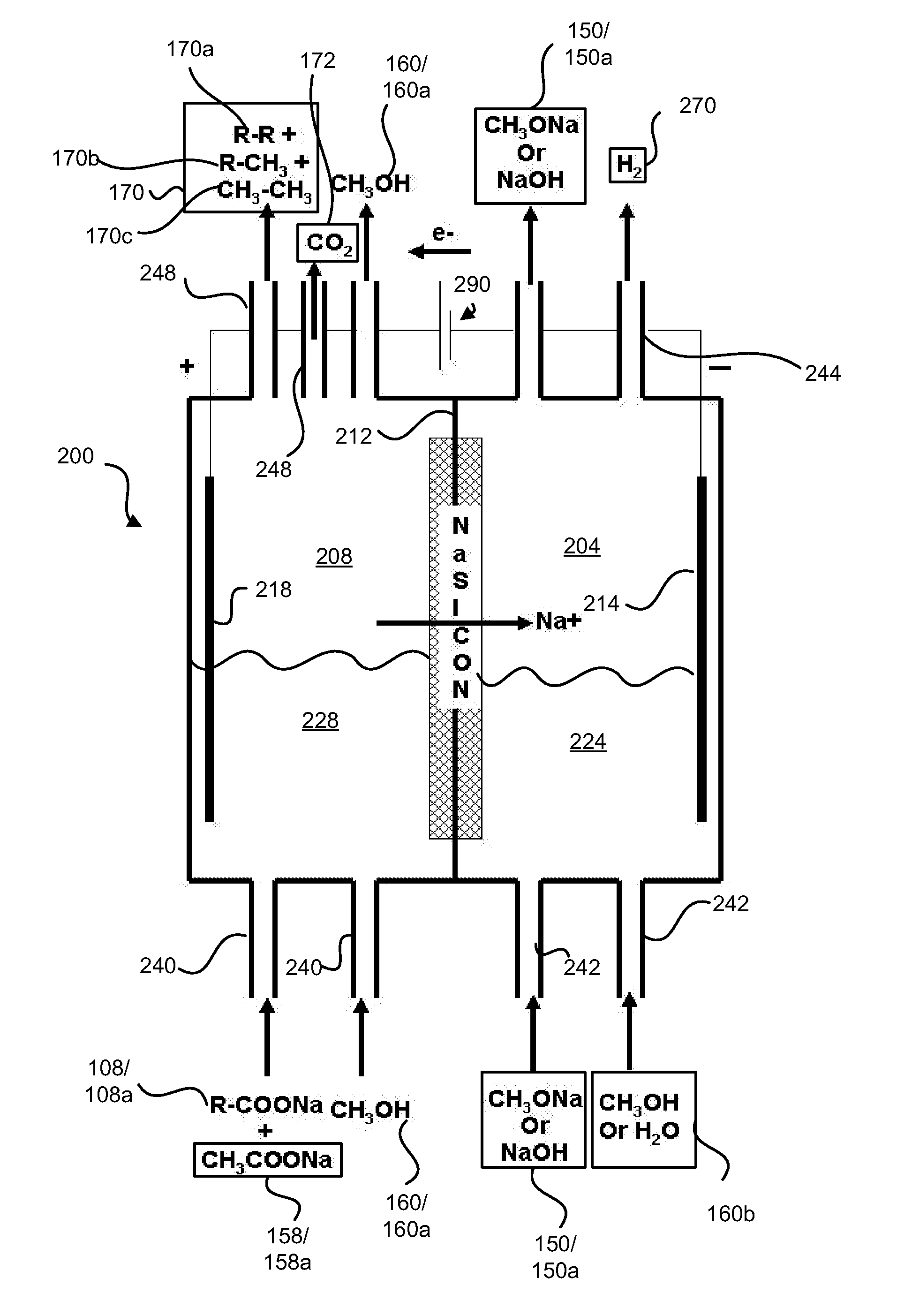

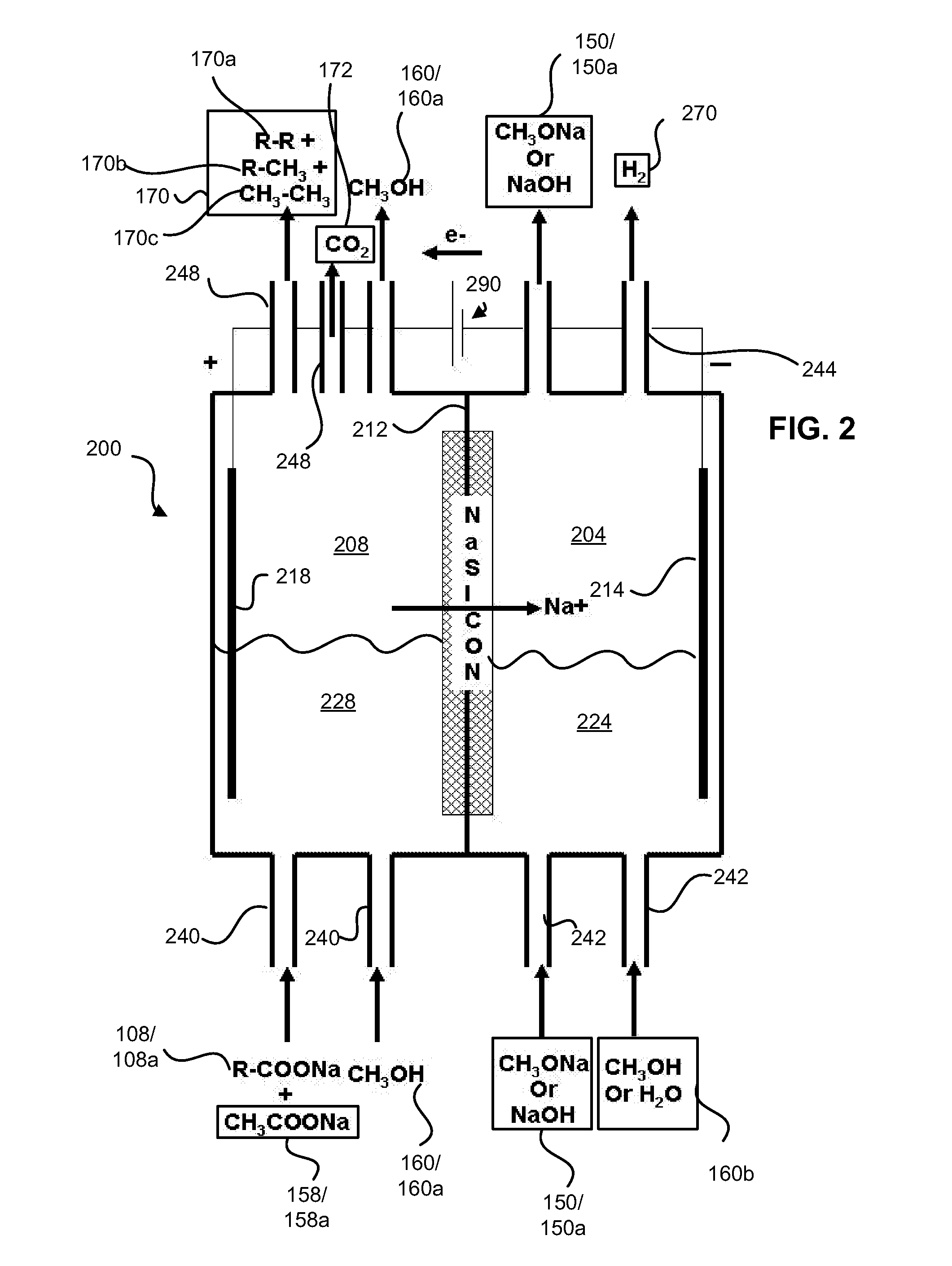

[0019]As noted above, the cell contains a membrane that comprises a sodium ion conductive membrane. This membrane selectively transfers sodium ions (Na+) from the anolyte compartment to the first catholyte compartment under the influence of an electrical potential, while at the same time preventing the anolyte and cat

Problems solved by technology

Unfortunately, hydroreacting is generally expensive because hydrogen gas is an expensive reactant.

Also, a catalyst is involved in this process, and such catalysts are often intoler

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential / voltage | aaaaa | aaaaa |

Login to View More

Abstract

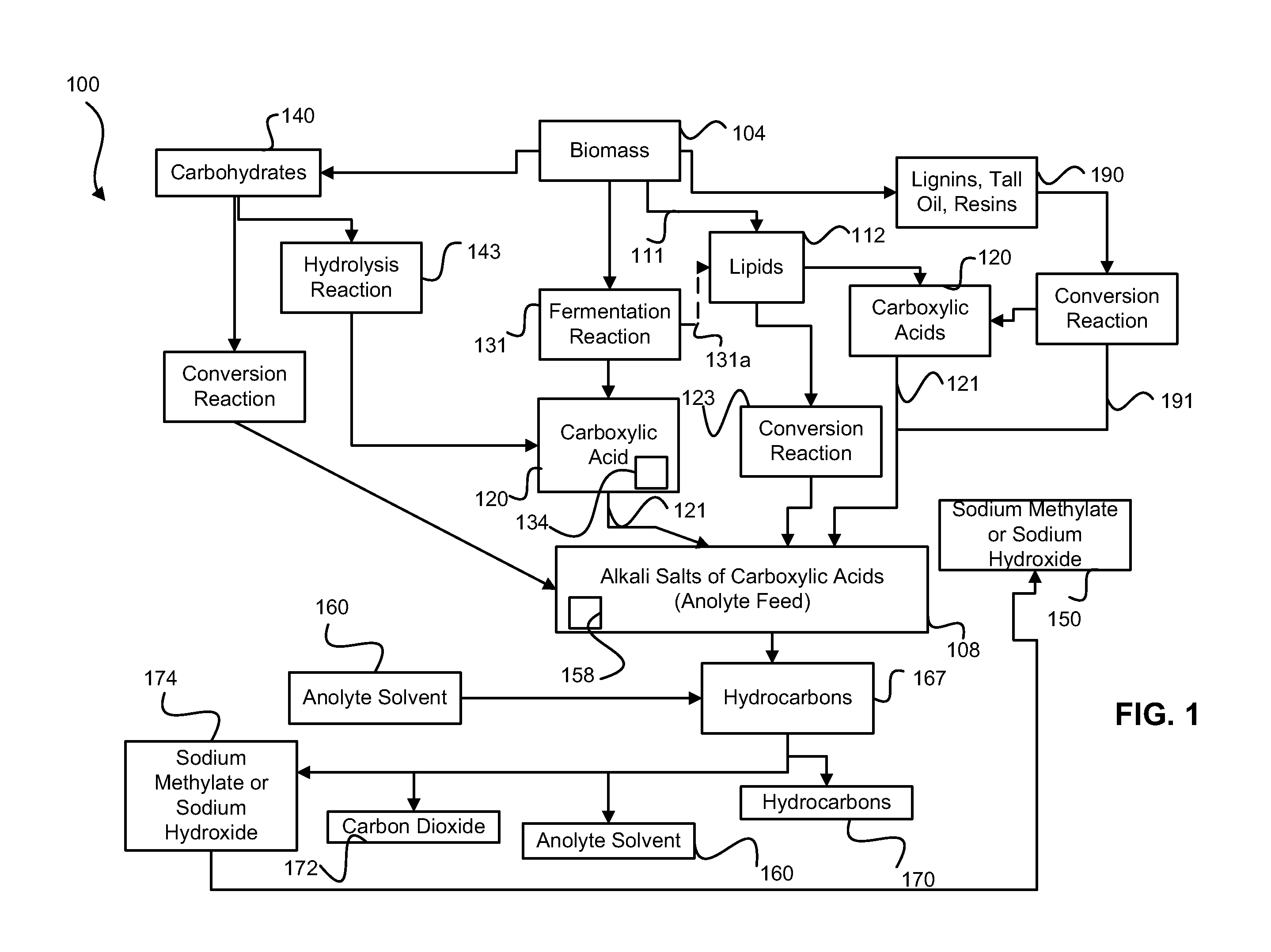

A method that produces coupled radical products from biomass. The method involves obtaining a lipid or carboxylic acid material from the biomass. This material may be a carboxylic acid, an ester of a carboxylic acid, a triglyceride of a carboxylic acid, or a metal salt of a carboxylic acid, or any other fatty acid derivative. This lipid material or carboxylic acid material is converted into an alkali metal salt. The alkali metal salt is then used in an anolyte as part of an electrolytic cell. The electrolytic cell may include an alkali ion conducting membrane (such as a NaSICON membrane). When the cell is operated, the alkali metal salt of the carboxylic acid decarboxylates and forms radicals. Such radicals are then bonded to other radicals, thereby producing a coupled radical product such as a hydrocarbon. The produced hydrocarbon may be, for example, saturated, unsaturated, branched, or unbranched, depending upon the starting material.

Description

CROSS-REFERENCED RELATED APPLICATIONS[0001]This application claims the benefit of U.S. Provisional Patent Application No. 61 / 228,078, filed on Jul. 23, 2009. This application also claims the benefit of U.S. Provisional Patent Application No. 61 / 258,557, filed on Nov. 5, 2009. This application also claims the benefit of U.S. Provisional Patent Application No. 61 / 260,961, filed on Nov. 13, 2009. These provisional patent applications are expressly incorporated herein by reference.BACKGROUND OF THE INVENTION[0002]Hydrocarbon fuels are currently used throughout the world. One specific example of a hydrocarbon fuel is gasoline (which includes octane). Another common hydrocarbon fuel is diesel fuel, which is used in diesel engines. Waxes, oils, and fuels are also desirable hydrocarbon products. Hydrocarbons are used in cosmetic and medical applications.[0003]Biomass is a renewable feedstock. Biomass may comprise lipids (such as fats or oils) that are available from plant, algal, or animal ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C25B9/00

CPCC10G3/00C25B3/10C10G2300/44C10G2300/1011C25B9/08Y02P30/20C25B3/29C25B9/19

Inventor BHAVARAJU, SAIKARANJIKAR, MUKUNDJOSHI, ASHOK V.HUNT, DAVID JOELCHITTA, PALLAVI

Owner CERAMTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com