Range hood

a range hood and hood technology, applied in the field of range hoods, can solve the problems of large noise, low efficiency and power consumption, and contaminating indoor and outdoor environment, and achieve the effects of rapid rotation, volume loss, flow loss and power consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]Further description will be given below in conjunction with accompanying drawings.

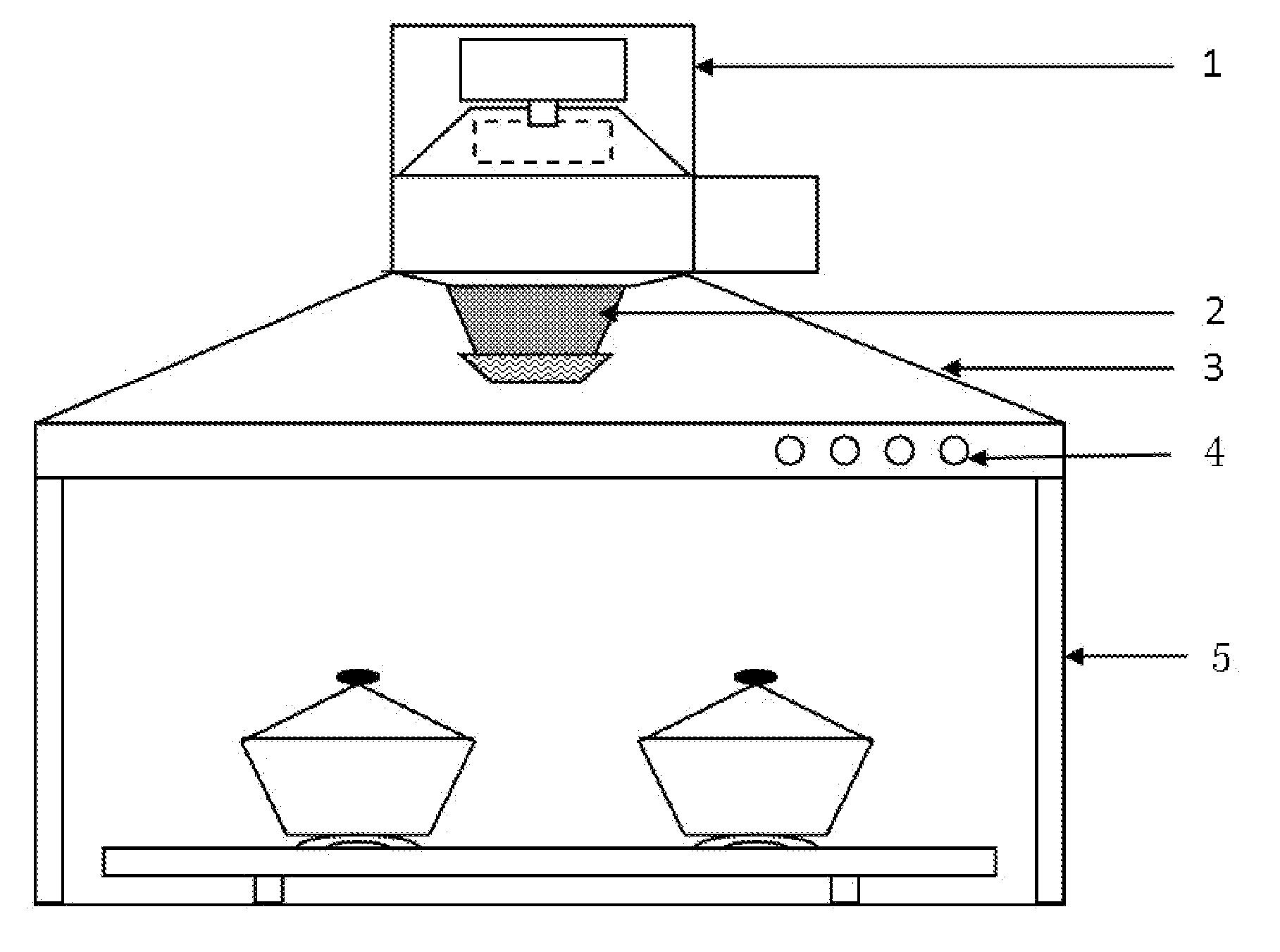

[0034]As shown in FIG. 1, a range hood of the invention comprises a fan 1, an oil filter 2, a cover 3, a fume exhaust cover 4, a light, and a switch 5.

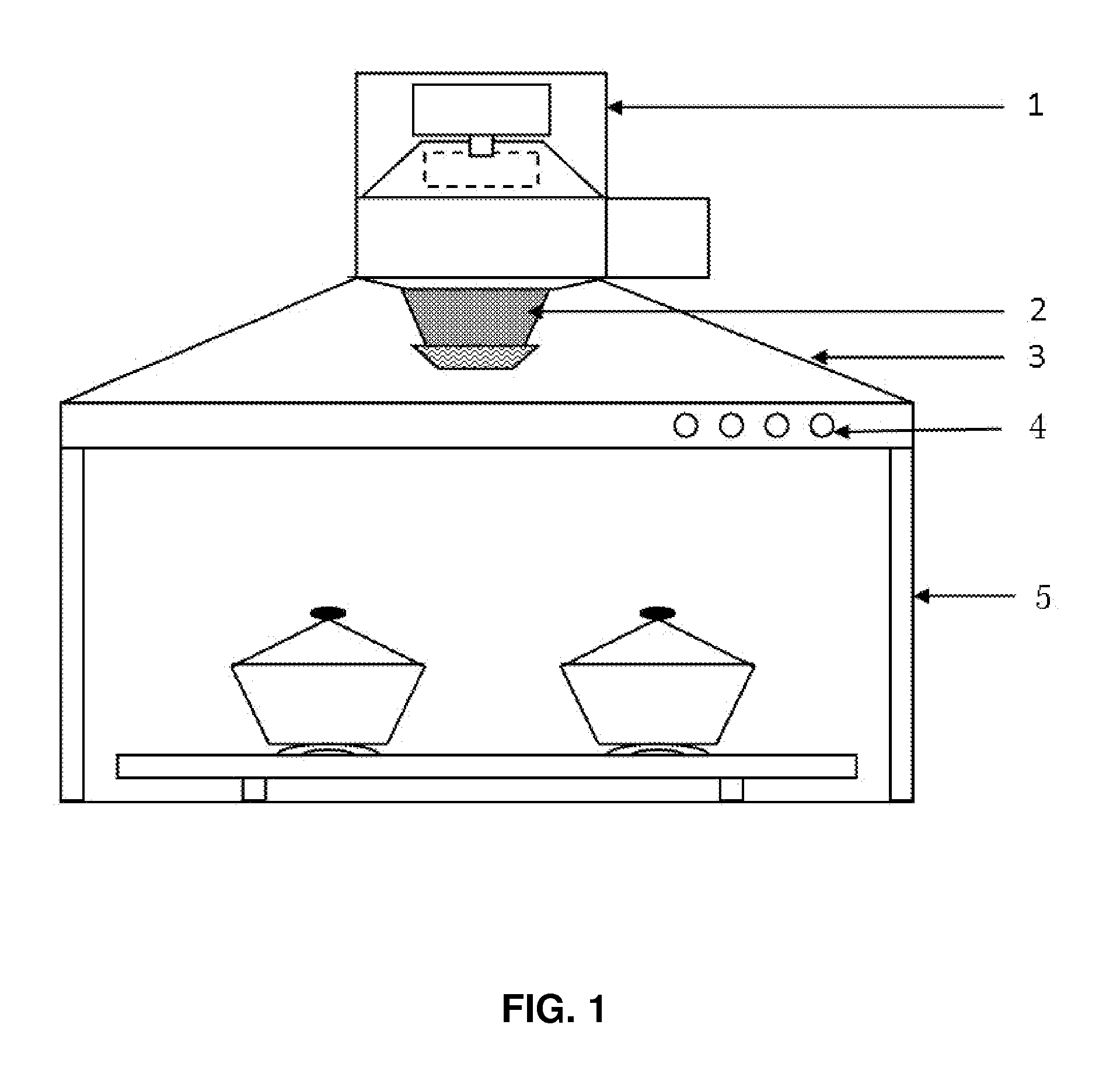

[0035]As shown in FIGS. 1—3, the fan 1 comprises a housing 12, an impeller 6, a swirl chamber 11, an impeller chamber 9, an air inlet 10, an air outlet 8, and a motor 7.

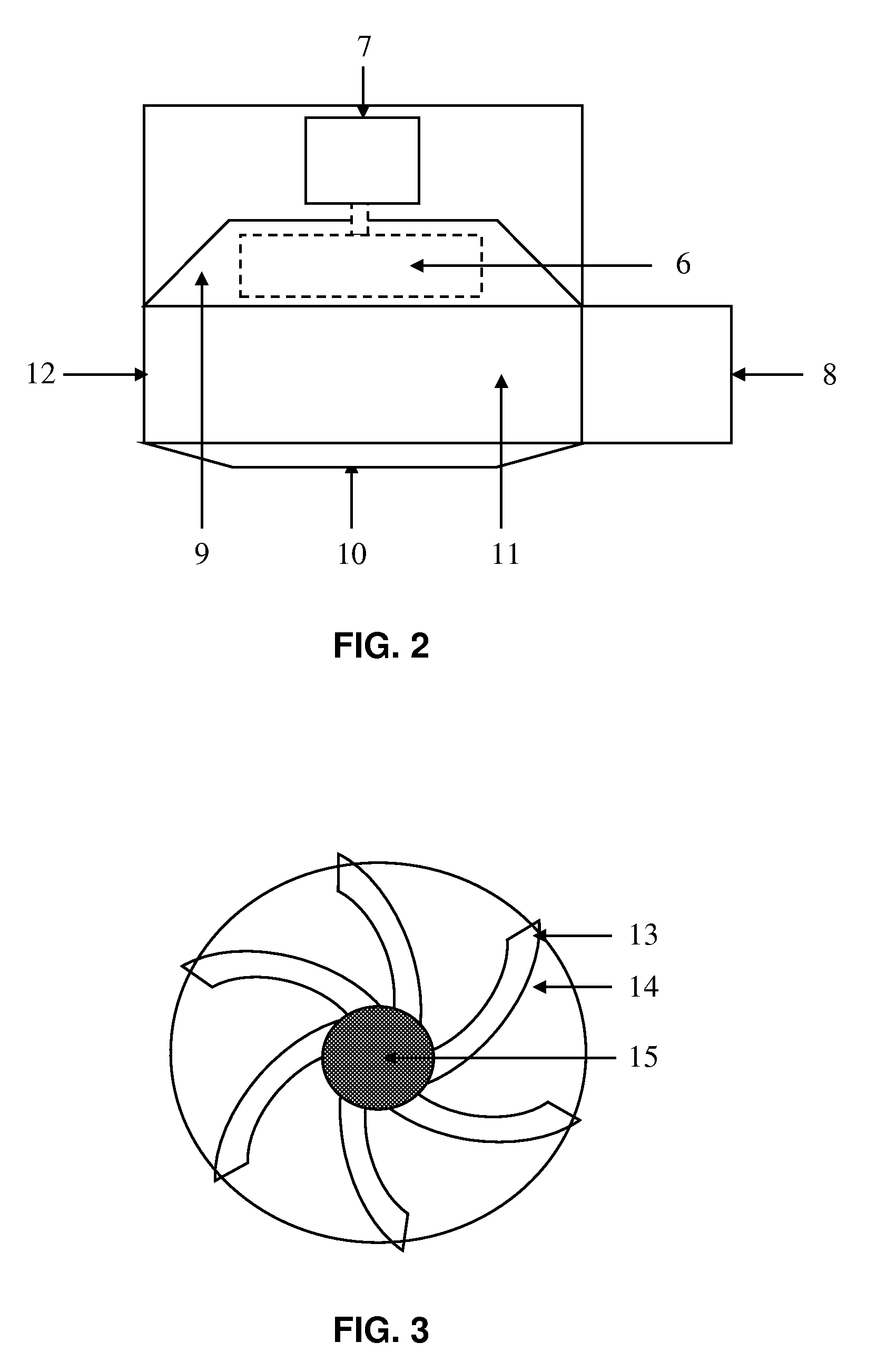

[0036]The impeller 6 of the fan 1 comprises at least one group of arc-shaped blades 13 each having a closed side and being enlarged in an axial direction.

[0037]The housing 12 of the fan 1 is a circular double-chamber or multi-chamber structure with the air inlet 10 and the air outlet 8. The housing 12 comprises a swirl chamber 11 and an impeller chamber 9.

[0038]The impeller 6 is disposed in the wheel chamber 9 and connected to the motor 7 disposed at the top of the housing 12.

[0039]The air inlet 10 is disposed at the bottom of the swirl chamber 11, and the air outlet 8 is disposed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com