X-ray irradiator

a technology of x-ray irradiator and x-ray tube, which is applied in the direction of x-ray tube structural circuit elements, basic electric elements, electric discharge tubes, etc., can solve the problems of difficult to deal with these connectors, and achieve the effects of reducing the size of the x-ray irradiator, preventing the occurrence of discharge, and reducing the difference in electric potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]Descriptions will be hereinbelow provided for the present invention, referring its embodiment as shown in the drawings.

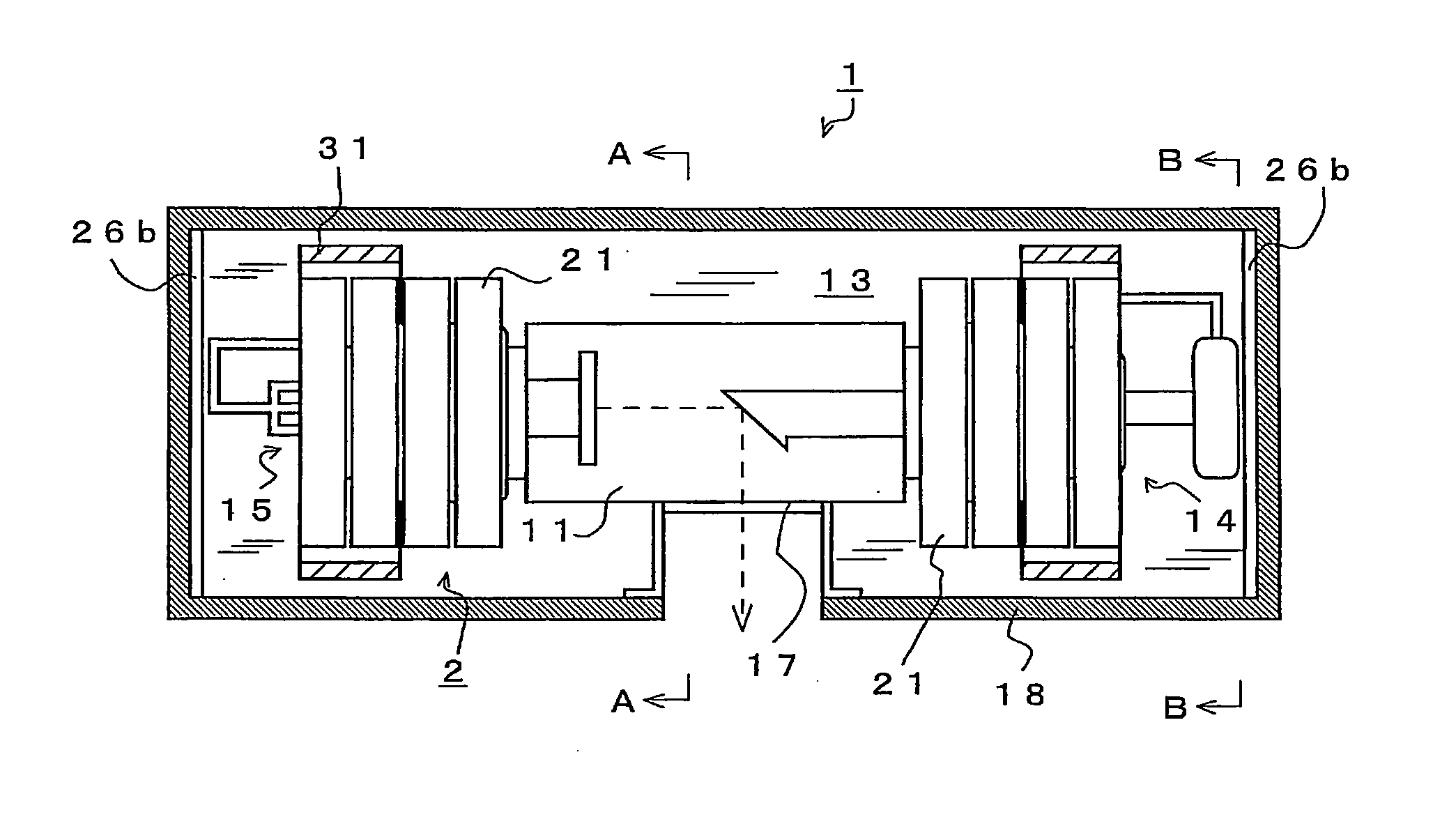

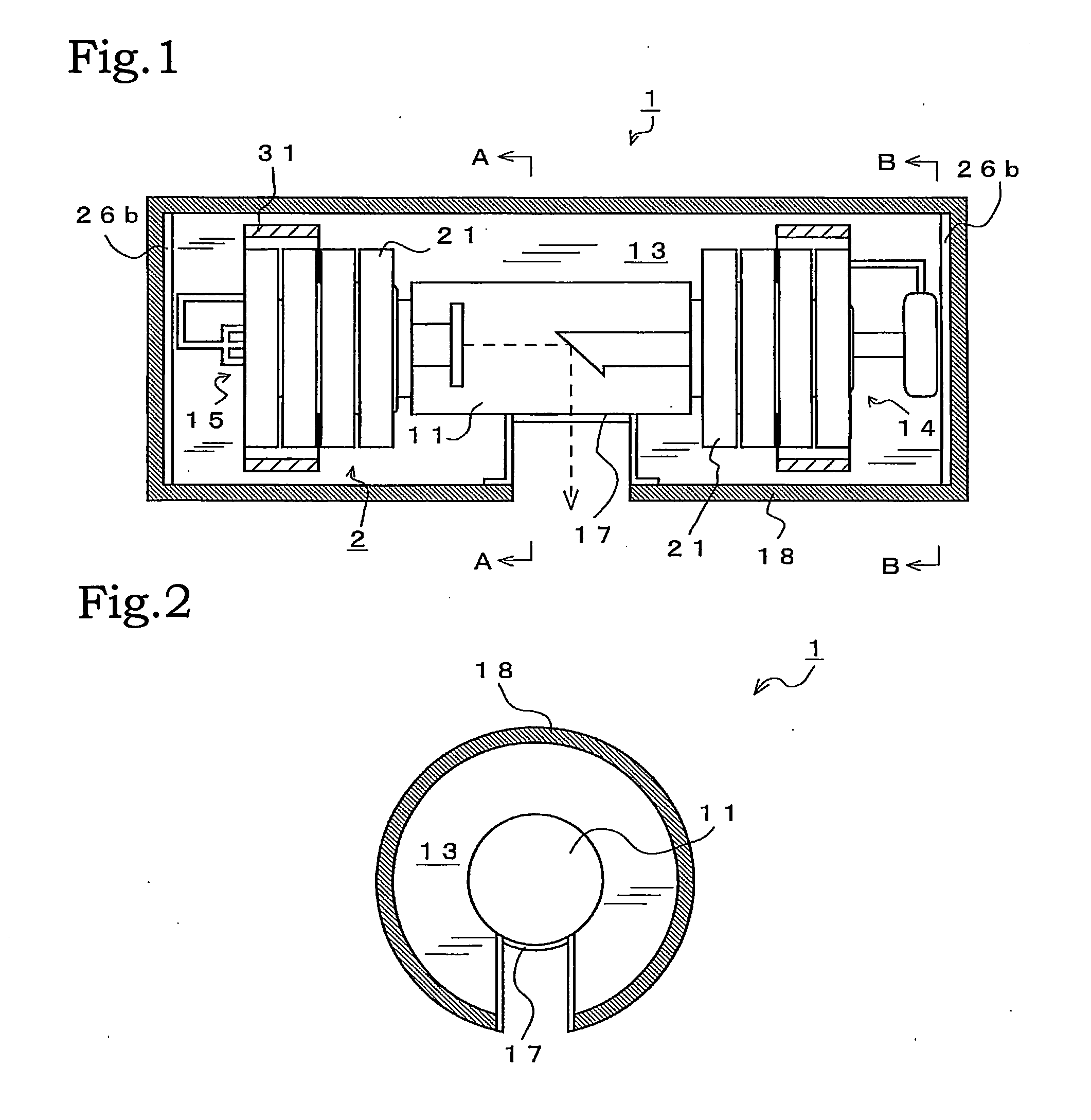

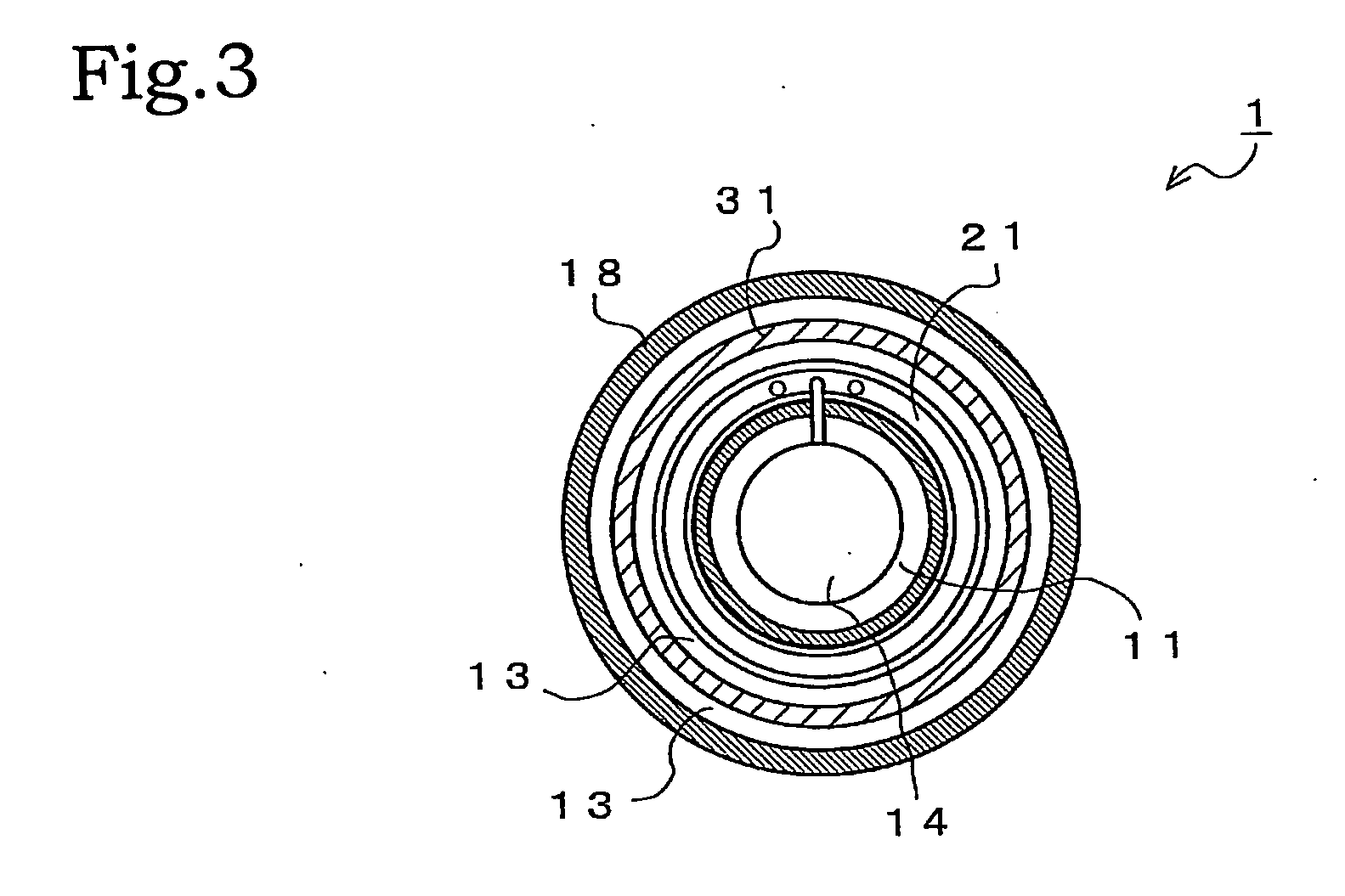

[0047]FIG. 1 shows a schematic of an X-ray irradiator 1. In the X-ray irradiator 1, a cylinder-shaped X-ray tube 11 is installed inside a casing 18, and four voltage amplifying units 21 are installed around each of an X-ray tube anode (hereinafter referred to as an “anode”) 14 and an X-ray tube cathode (hereinafter referred to as a “cathode”) 15. A high-voltage generator 2 including the multiple voltage amplifying units 21 is connected to the anode 14 and the cathode 15, and is also connected to an unillustrated external power supply.

[0048]Auxiliary electric potential plates 31 are installed around the high-voltage generator 2. The auxiliary electric potential plates 31 are capable of reducing the difference in electric potential around the high-voltage generator 2, and accordingly preventing discharge. In addition, an insulation oil 13 or an insulation resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com