Titanium alloy golf club head

a golf club head and titanium alloy technology, applied in the field of golf club heads, can solve the problems of reducing the strength and rigidity of the head, changing the center of gravity of the head, reducing the thickness of the wall, etc., and achieves the effect of improving the efficiency of hitting, increasing the volume of the head, and increasing the efficiency of hitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]Hereinafter, implementations will be described in detail with reference to the accompanying drawings.

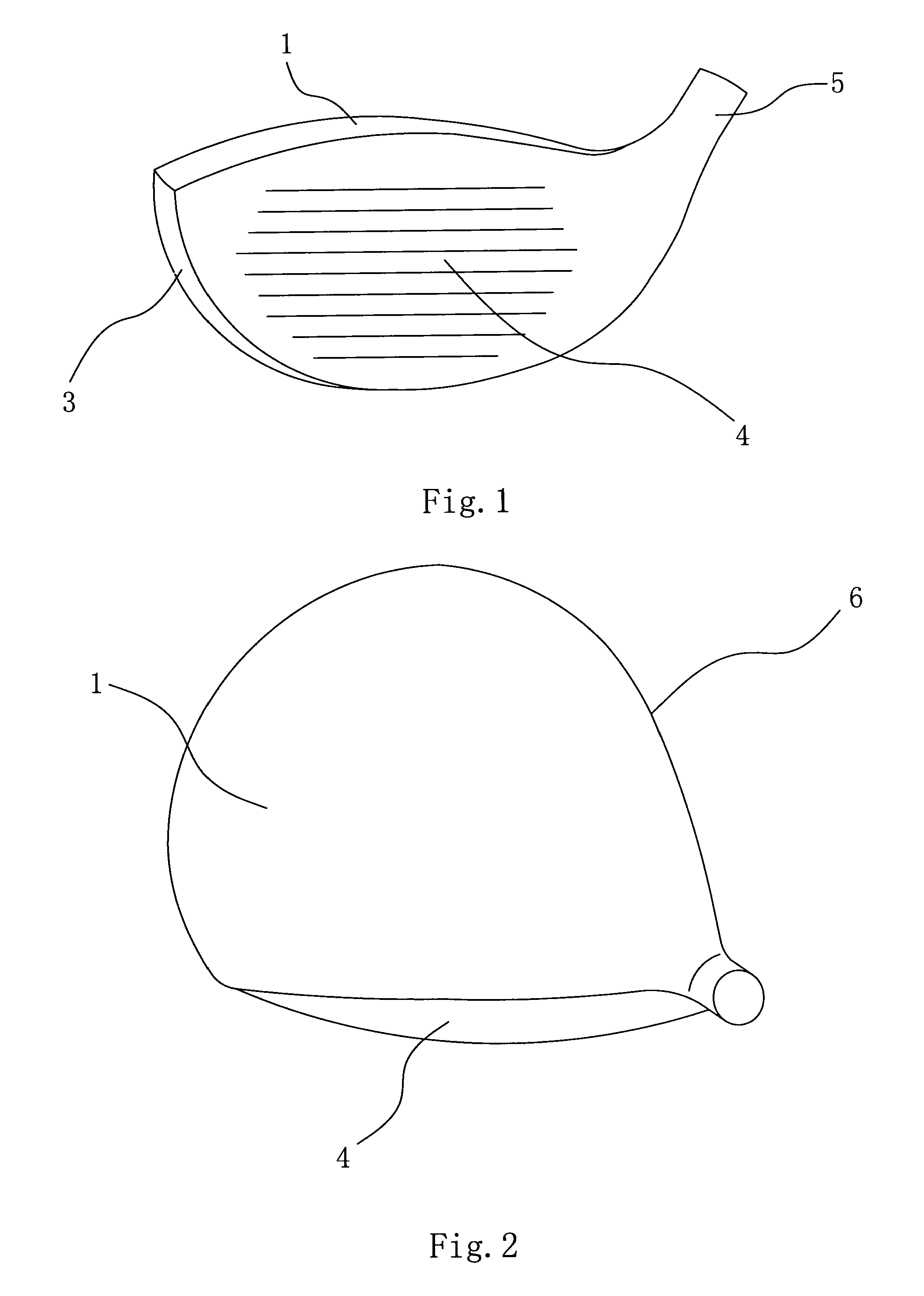

[0019]Referring to FIGS. 1 and 2, a golf club head 10 comprises a head base 3, a hitting face 4 at a front edge of the head base 3 and a top lid 1 on the top of the head base 3. The head base 3 has a neck 5 for connecting with a club (not shown). The top lid 1 has an inside surface 2 and an outside surface 6 opposite to the inside surface 2. The head base 3, the hitting face 4 and the top lid 1 are connected with each other to form a close entirety.

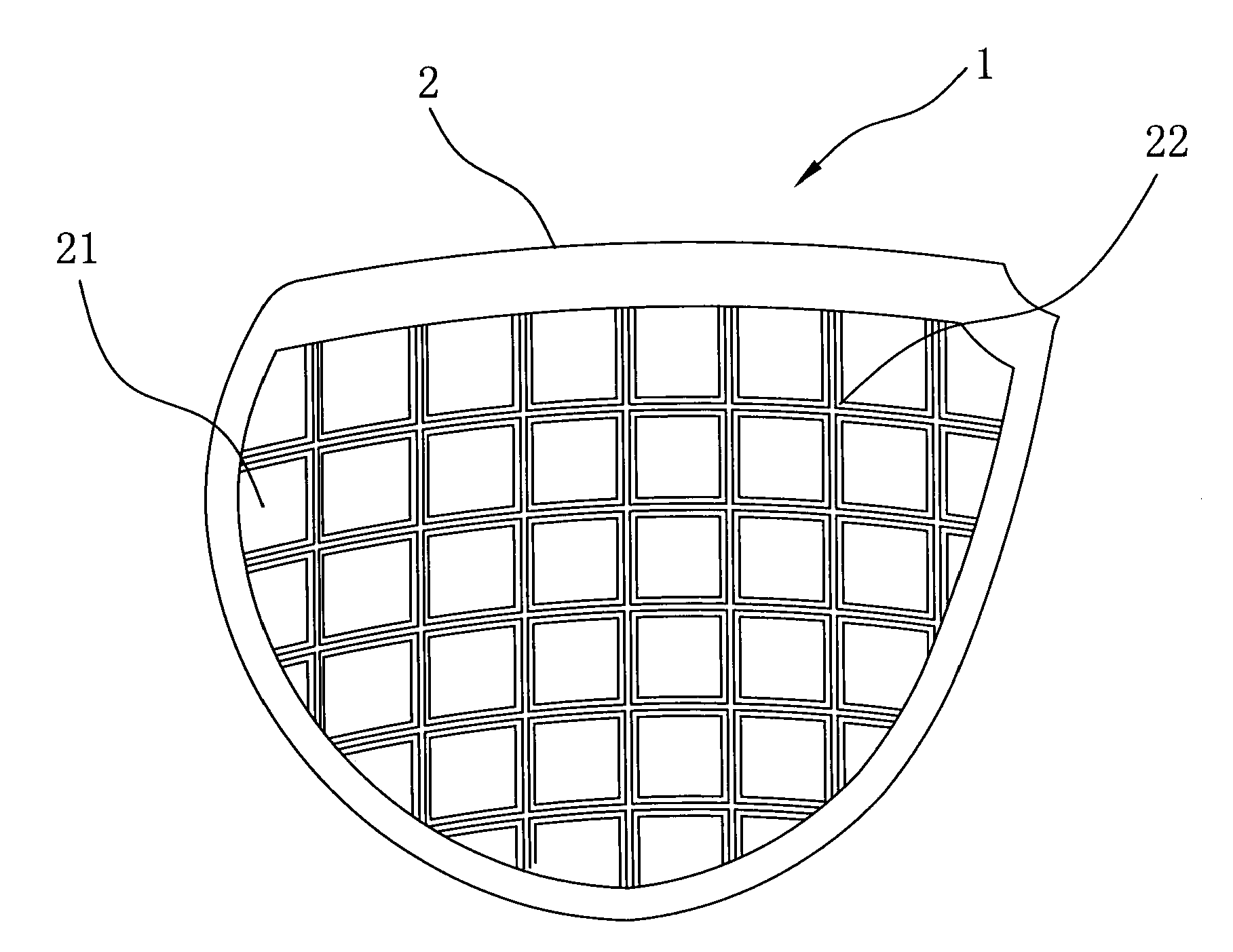

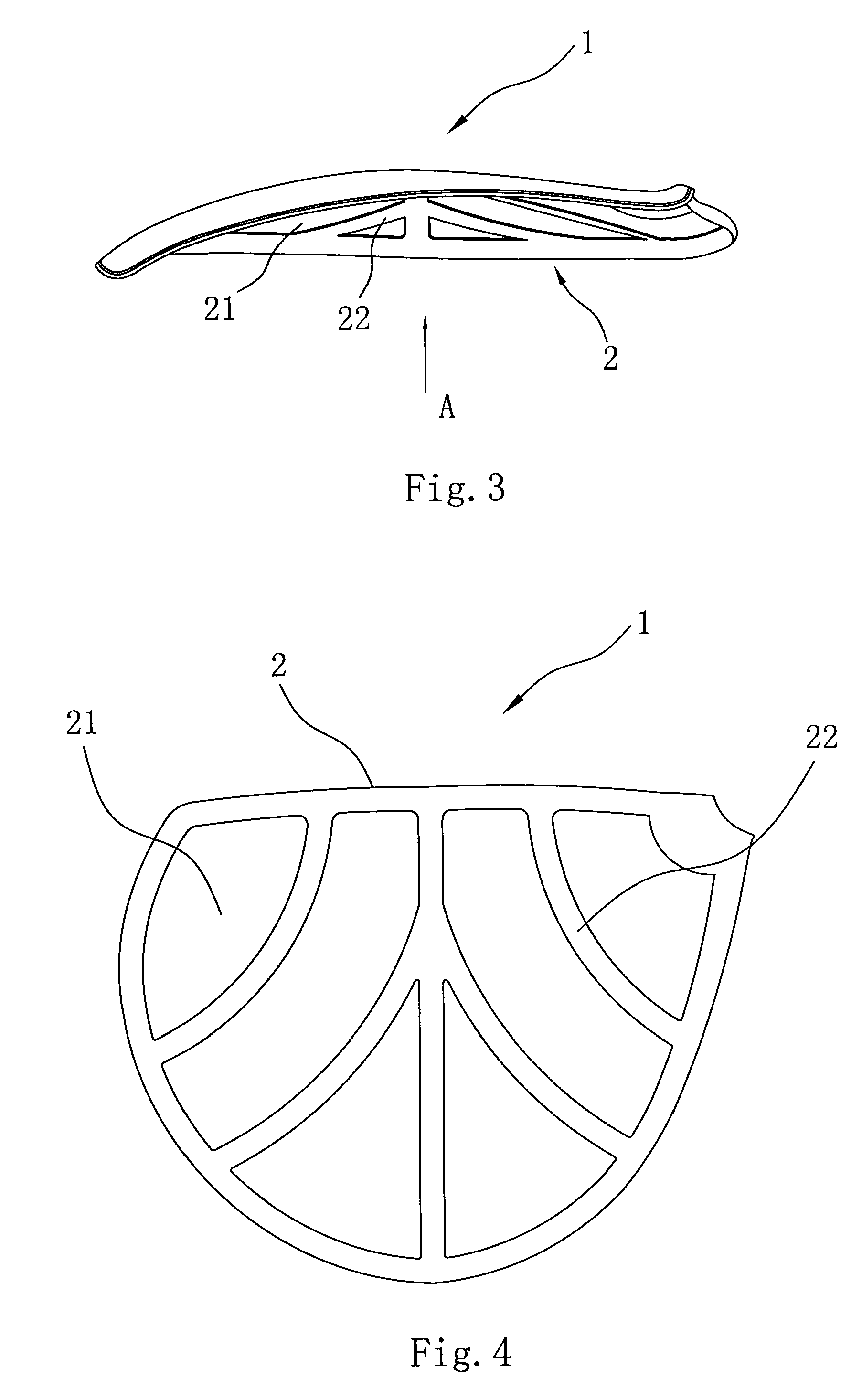

[0020]Now referring to FIGS. 3 and 4, a plurality of recesses 21 are formed in the inside surface 2 of the top lid 1. The plurality of recesses 21 are arranged bilateral-symmetrically, and each of the plurality of recesses 21 has the same depth. In this condition, the weight of the top lid 1 may be symmetrically arranged such that the club may swing more smoothly.

[0021]FIG. 4 shows an example of the arrangement for the recesses 21. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com