Sawyer-singleton geothermal energy tank

a geothermal energy tank and solitary technology, applied in indirect heat exchangers, greenhouse gas reduction, lighting and heating apparatus, etc., can solve the problems of not being able to use dense urban areas, the water body must be 34 of an acre, and the method cannot be used in dense urban areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

—FIRST EMBODIMENT

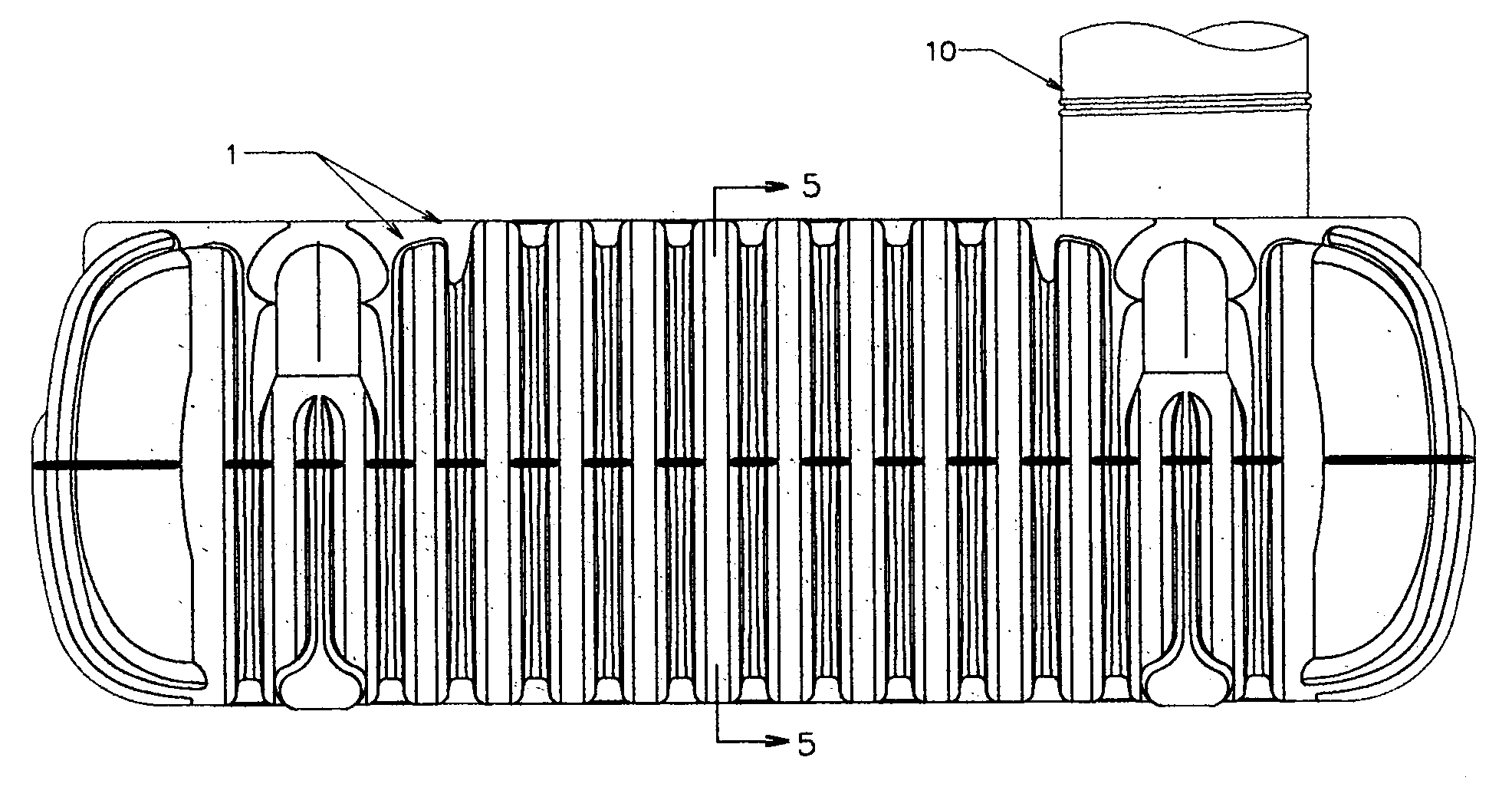

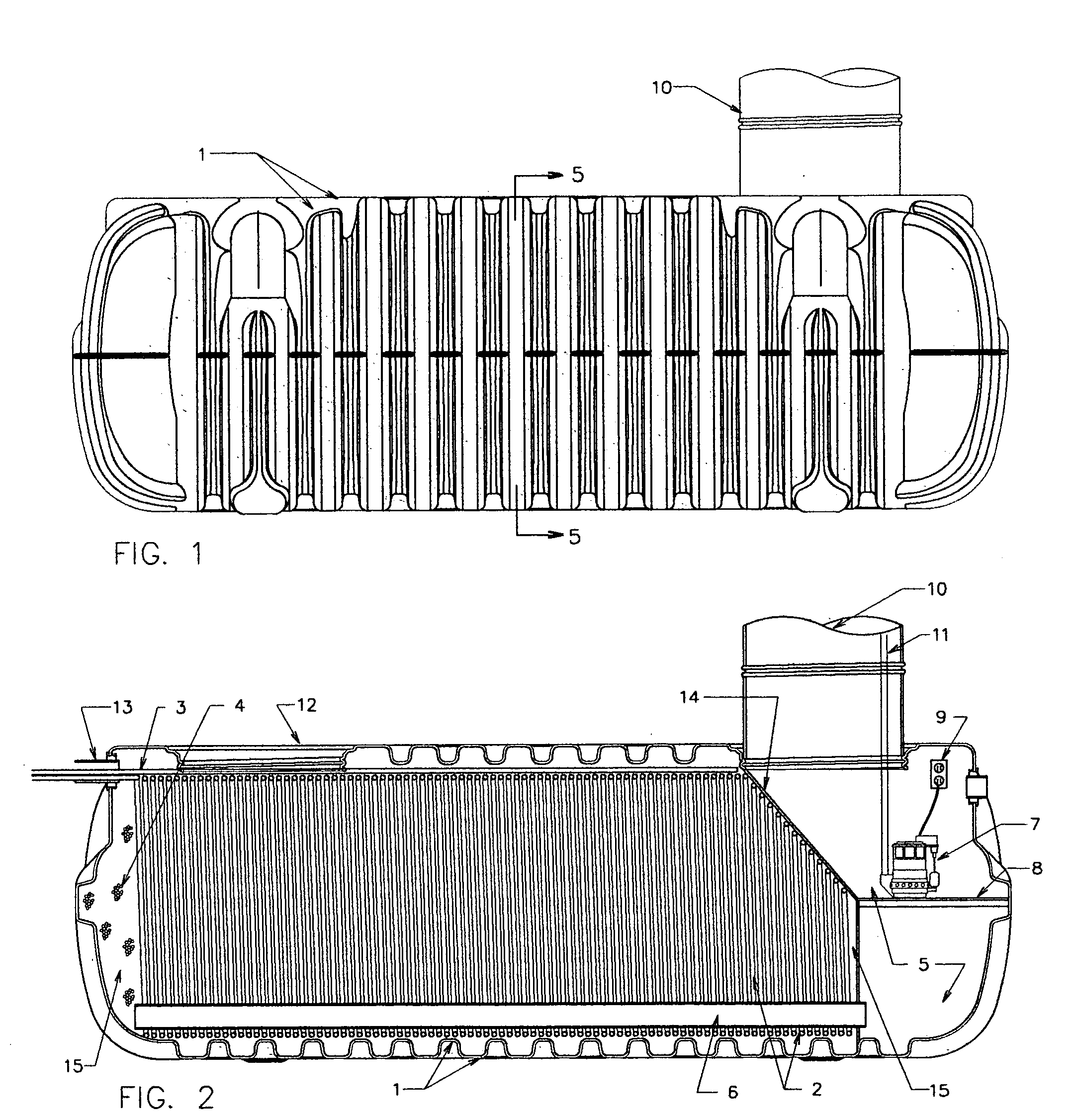

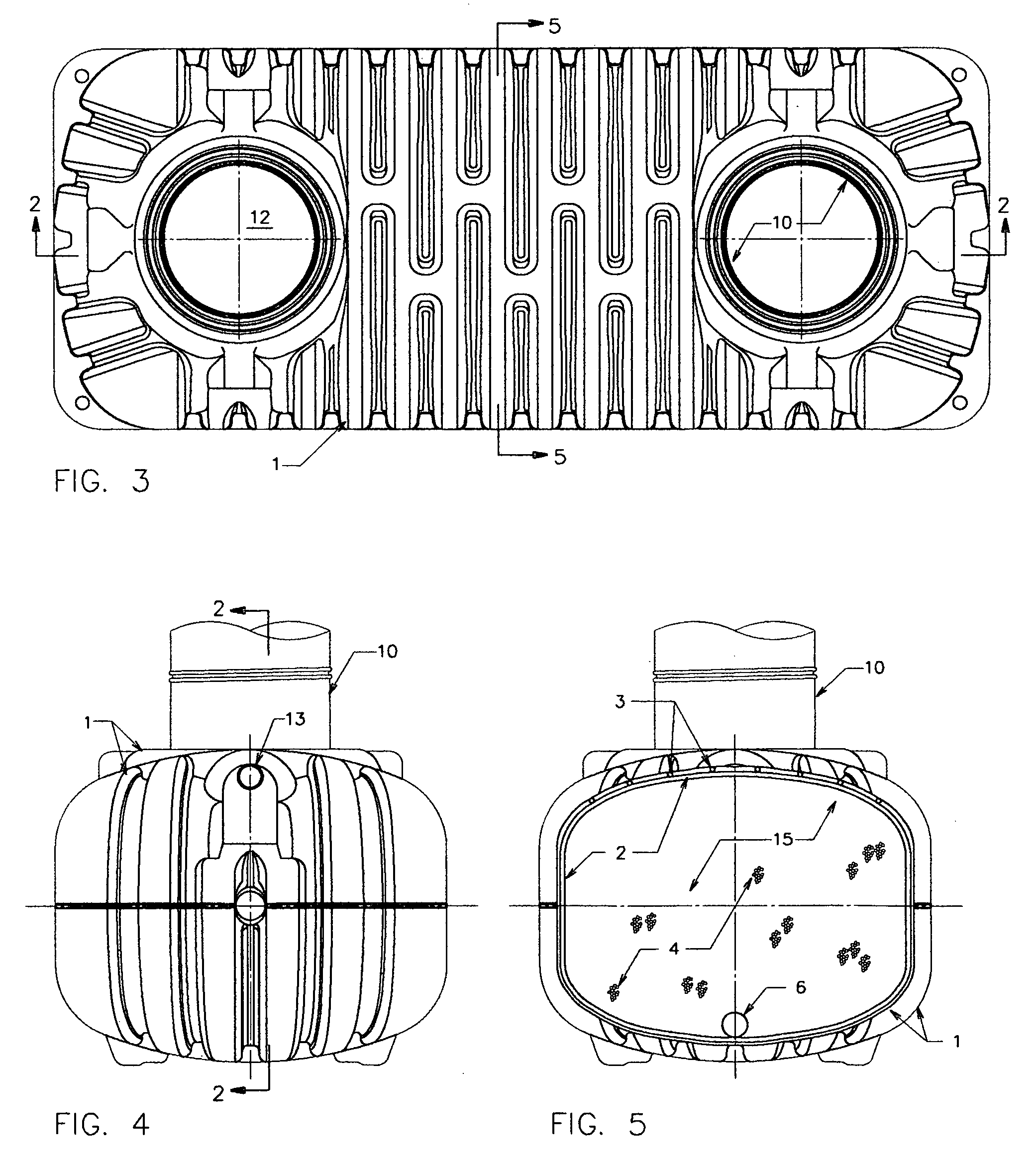

[0050]Referring to Sheets 1 / 2 and 2 / 2, the first embodiment of the closed loop geothermal energy exchange tank comprises a rectangular structure (1) capable of being buried within the earths' geothermal zone without failure. Attached to the interior walls of the structure is a continuous coil of 11 / 16″ diameter plastic tubing spaced ½ inches apart (2). In contact with the plastic tubing is a mass of permeable soil (4), filling the interior of the energy exchange chamber. If needed, water is introduced to the interior soil mass by ¾″ diameter perforated plastic pipes (3), which pass through a conduit sleeve (13) and runs the length of an energy exchange chamber (15) containing the plastic tubing.

[0051]The water is used to regulate the temperature of the interior soil mass when needed. The interior soil mass, in turn, removes the heat from the cooling fluid flowing within a continuous coil of plastic tubing (2) that forms a closed loop with the heat pump.

[0052]After i...

embodiment # 1

Alternate Embodiment #1

[0055]The interior soil mass referenced in FIGS. 2 and 5 of the first embodiment is partially replaced by a light weight structure, such as Styrofoam, to reduce both the weight of the containment tank and limit the work required on site to install the interior soil mass. This light weight structure will be located at or near the center of the tank and will allow a reduced thickness of the interior soil mass to be in contact with the coils located on the interior wall of the containment tank.

embodiment # 2

Alternate Embodiment #2

[0056]The interior soil mass referenced in FIGS. 2 and 5 is partially replaced by a smaller interior tank of the same shape as the original tank. This interior tank would be located such that a reduced thickness of the interior soil mass will remain in contact with the coils located on the interior walls the containment tank. The internal tank will serve several purposes. The first being to reduce weight and jobsite labor by reducing the amount of interior soil mass required. Secondly, the interior tank will serve as the water overflow chamber, thus reducing the overall length of the containment tank and eliminating the perforated drain pipe.

[0057]The bottom of the interior tank would be perforated, allowing water to, under hydrostatic pressure, fill the interior tank. The sump pump, the pump platform, the water discharge pipe, the power source and the manhole extension section, would be incorporated into the interior tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com