Callapsible shed

a shed and egress door technology, applied in the field of egress door, can solve the problems of affecting the work efficiency of workers, affecting the safety of workers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

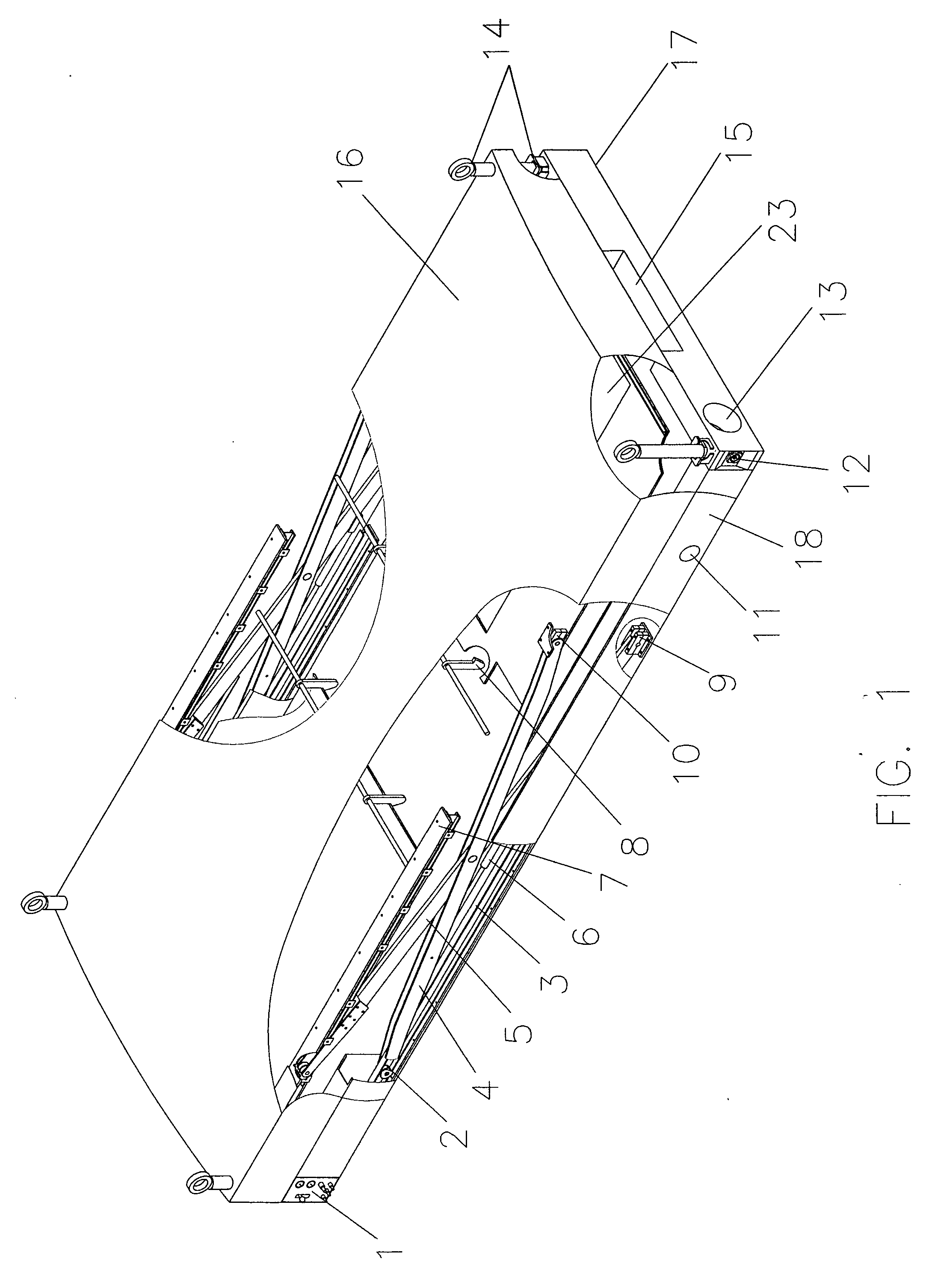

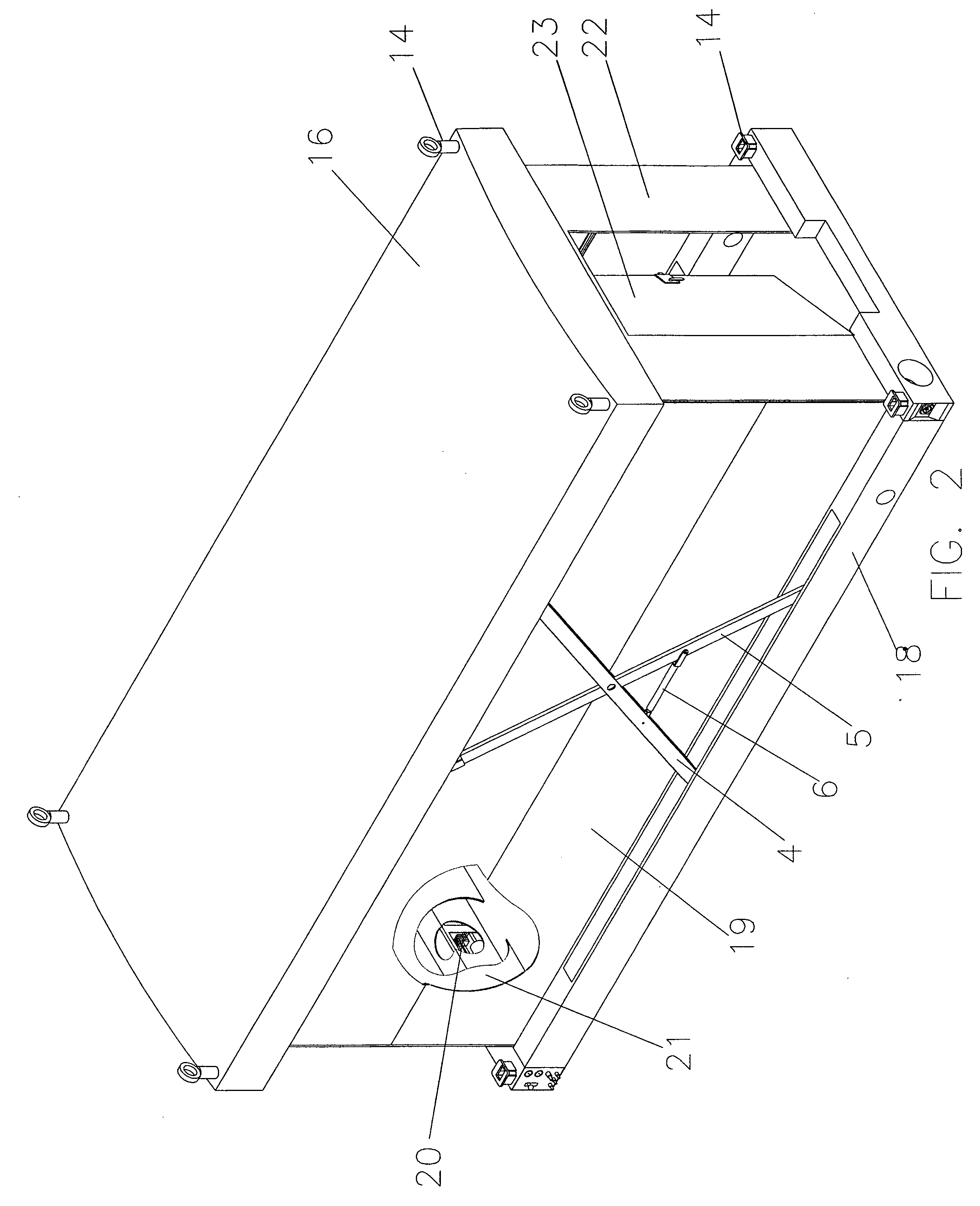

; DETAILED DESCRIPTION—FIG. 1 AND FIG. 2 NUMERIALS 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18&23: FIG. 2, NUMERIALS 19, 20, 21, 22&23

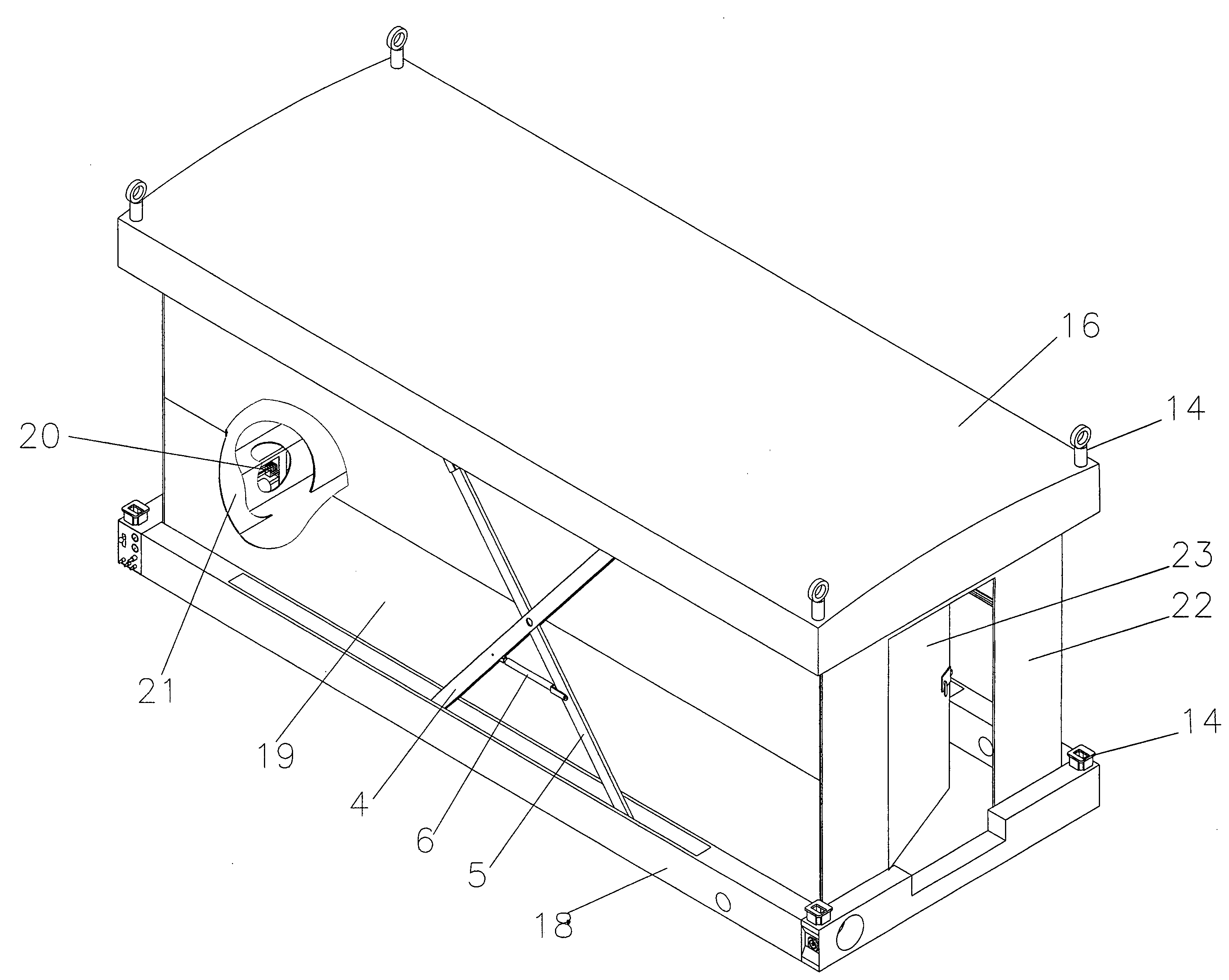

[0011]Embodiment One of the Invention is illustrated in FIG. 1 (perspective view). The invention is set over an aircraft carriers launch tube valve assembly by a crane. The invention is a frame with a roof section (16), bottom section (18), panel locks (8), end panels (21), door panels (22), door (23), control panel (1) connected to a ram (6) which are connected to the arms (4&5). There are two bottom arms “female” and one upper arm “male” that form an X. The arms are contiguous. There is a track and arm housing (18) containing the lower guide rail (3), guides (2) and the upper guide rail (7) also fixed journal boxes (9&10). There is a deck seal (17). There are container twist locks (14).

[0012]A Continuation of the Embodiment One of the Invention is illustrated in FIG. 2 (perspective view).

[0013]Shown in the FIG. 2, is folding side p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com