Retrievable hydraulic subsea bop control pod

a hydraulic subsea and control pod technology, applied in the direction of sealing/packing, drilling pipes, borehole/well accessories, etc., can solve the problems of affecting the operation of the subsea bop control pod, and requiring the replacement of existing control pods with frustoconical hydraulic receptacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

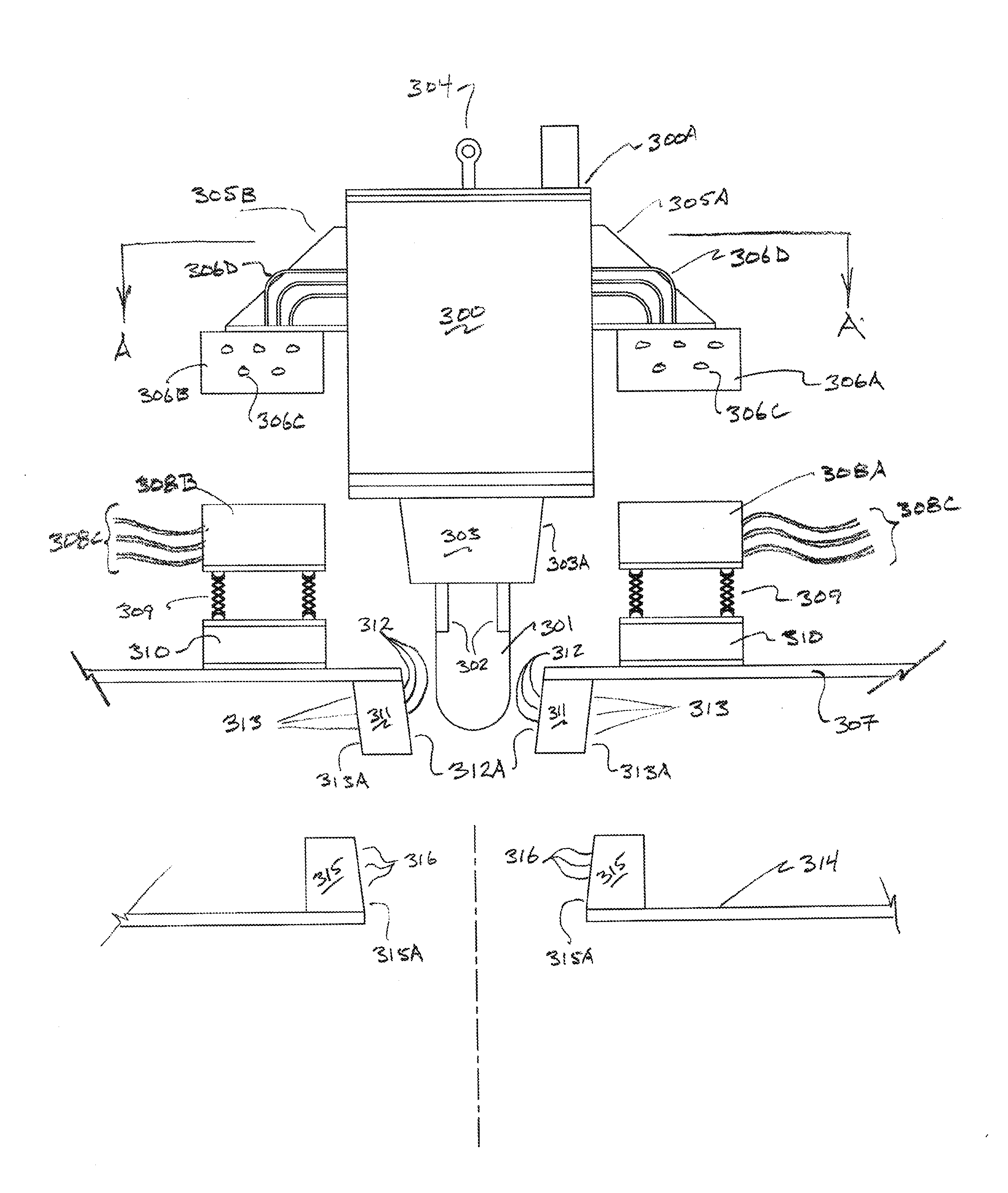

[0047]Refer now to FIG. 3, which shows a preferred embodiment of the present invention. Control pod 300 has umbilical junction plate 300A, male member 301 with latching mechanism 302, male hydraulic connector 303 with frustoconical surface 303A, and control pod deployment cable attachment point 304.

[0048]Control pod 300 also has radial connector brackets 305A and 305B, with attached pod umbilical connectors 306A and 306B, which have hydraulic ports 306C.

[0049]Pod umbilical connectors 306A and 306B are hydraulically connected to the valving inside the control pod 300 by umbilical connector piping 306D. As shown, umbilical connector piping 306D by-passes umbilical junction plate 300A; in this embodiment, umbilical junction plate 300A may be eliminated in order to save weight in control pod 300.

[0050]Alternately, umbilical junction plate 300A may be retained, and umbilical connector piping 306D may be run from pod umbilical connectors 306A and 306B to the hydraulic connectors on the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com