Extension shaft for holding a tool for rotary driven motion

a technology of extension shaft and rotary drive, which is applied in the direction of manufacturing tools, portable drilling machines, mechanical apparatuses, etc., can solve the problems of difficult to use the powered instrument in limited access areas, ineffective use of hand-held instruments in spatially restricted or difficult-to-reach locations, etc., and achieves the effect of increasing the angular variation and effective operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

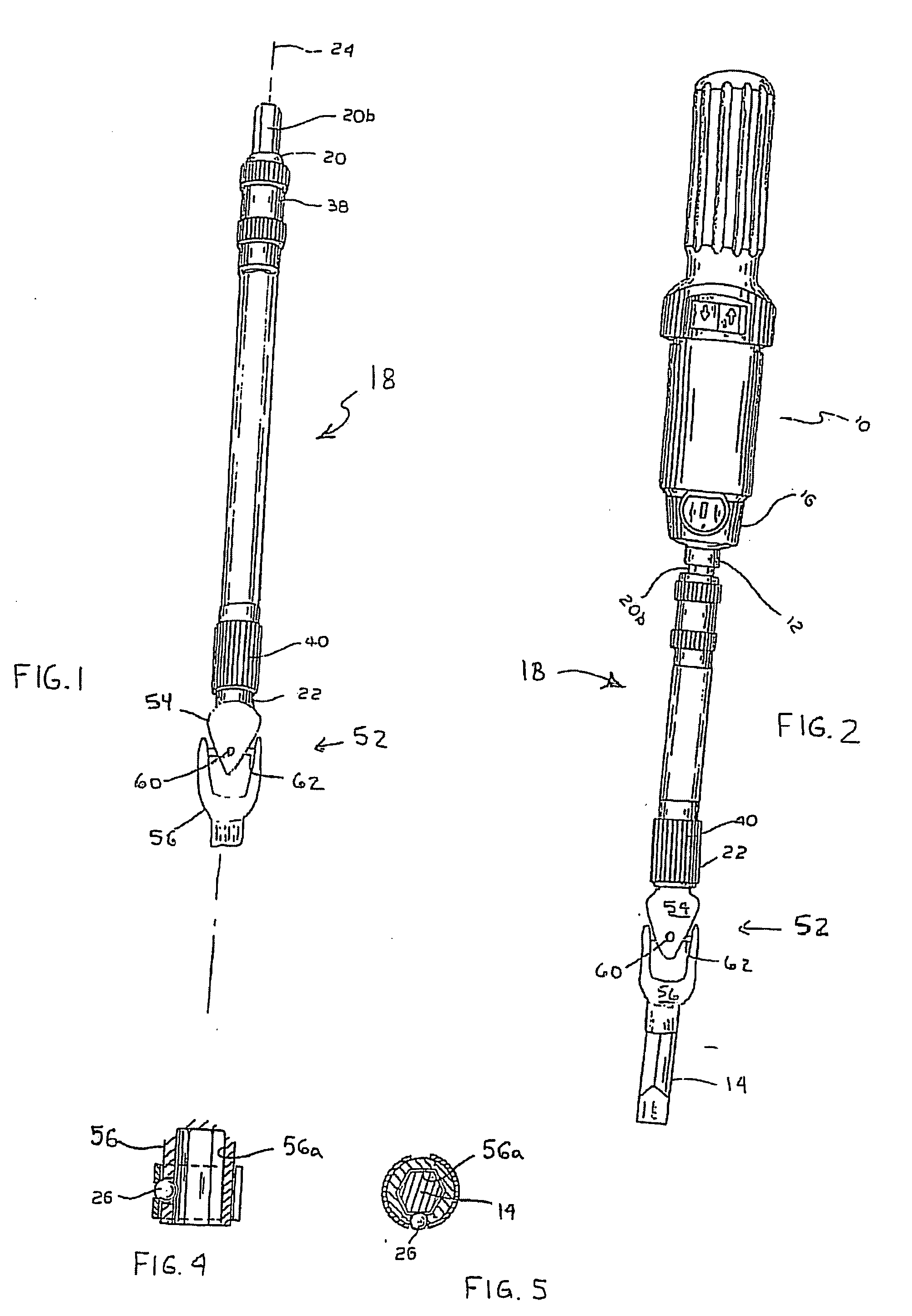

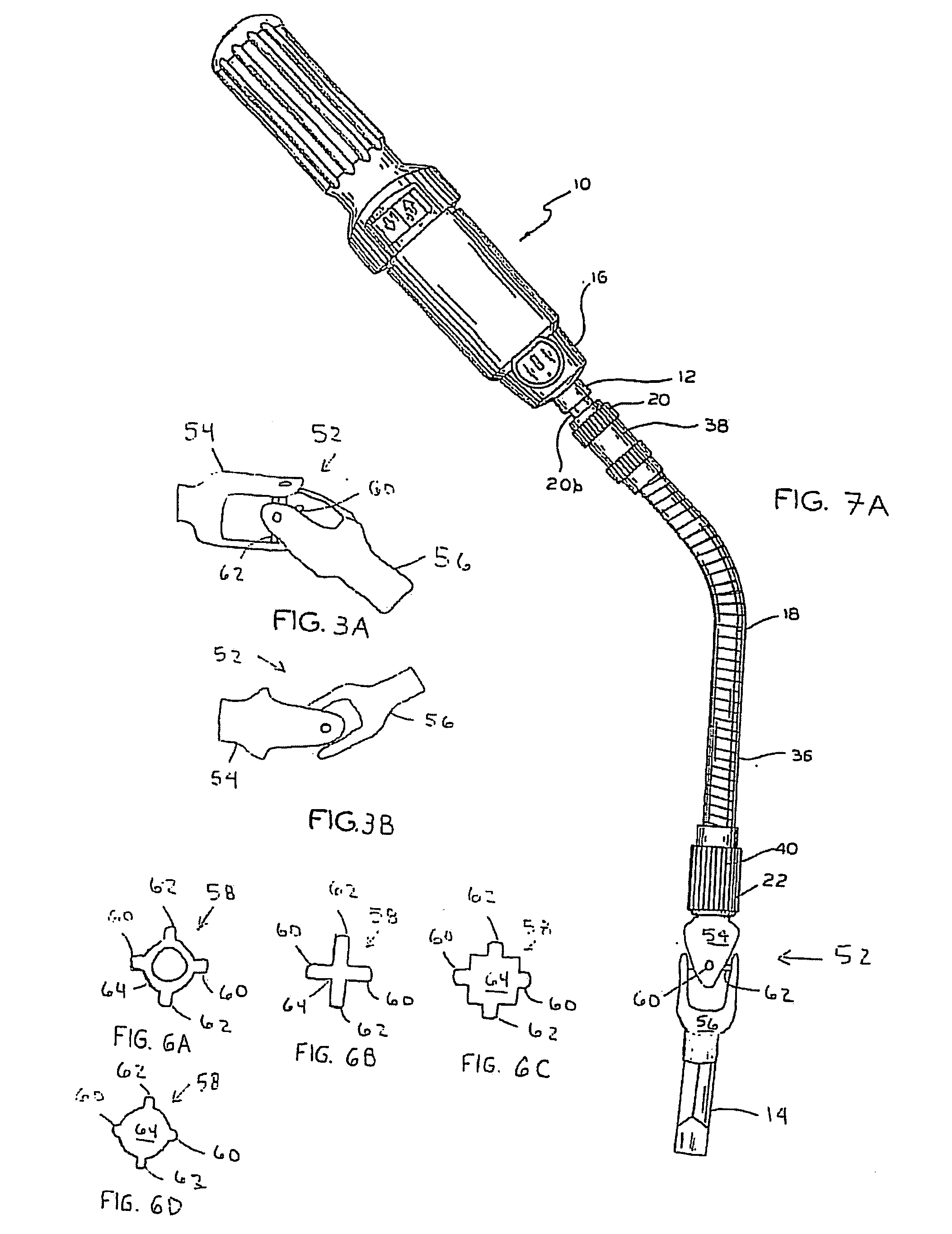

[0035]While this invention is susceptible to embodiments in many different forms, there are shown in the drawings and will herein be described in detail, preferred embodiments of the invention with the understanding that the present disclosures are to be considered as exemplifications of the principles of the invention and are not intended to limit the broad aspects of the invention to the embodiments illustrated.

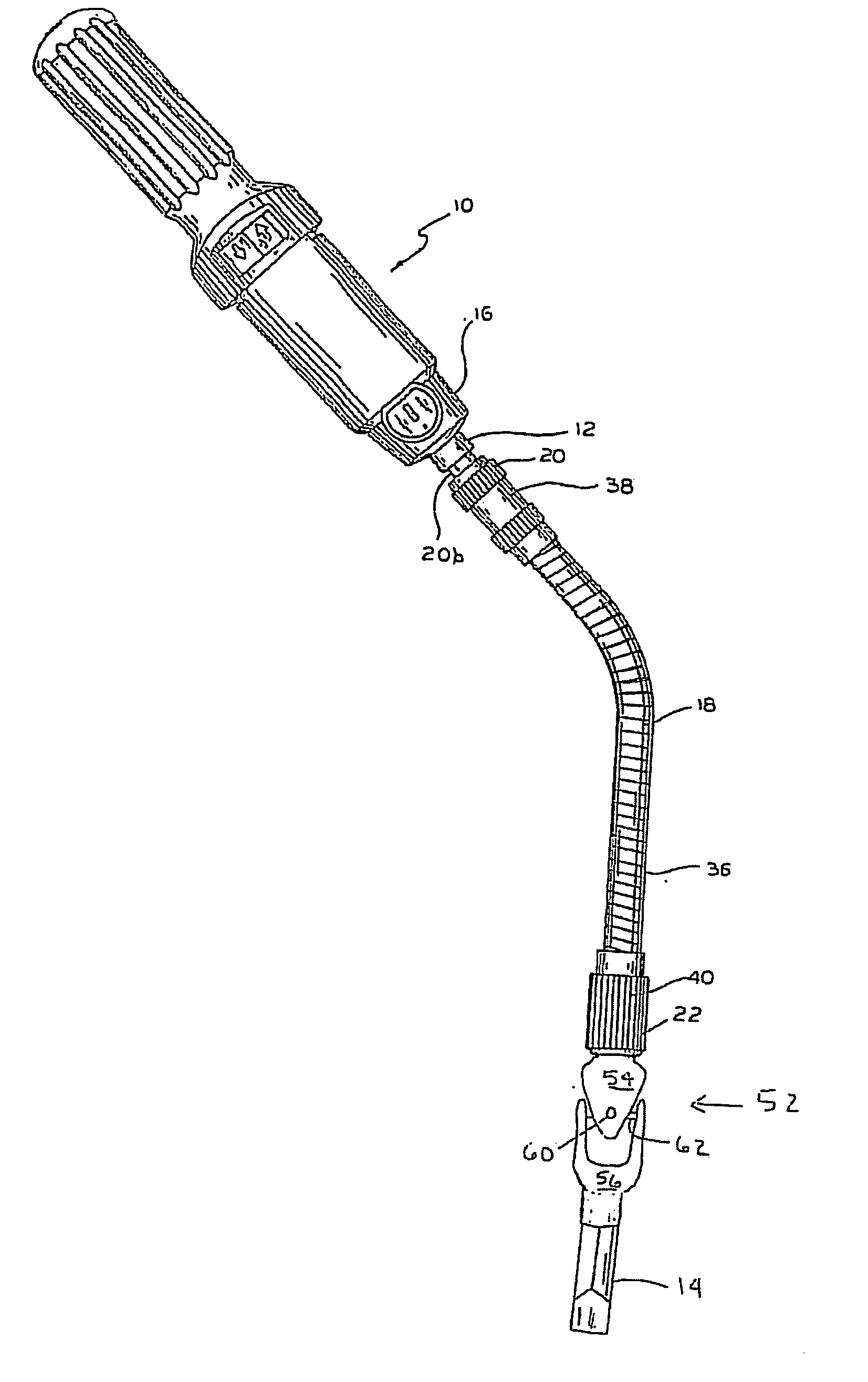

[0036]Referring to the drawings, and first to FIGS. 1 and 2, the reference numeral 10 designates generally a handheld instrument or piece of equipment, e.g., screwdriver, drill; having a chuck 12 for connection to an extension shaft 18 for rotary driven motion at one end 16 thereof. The extension shaft 18 includes a first end 20 adapted to cooperatively extend from, or attach or connect with, the chuck 12; and, a second end 22 that may similarly be adapted for attachment or extension there from and to hold a tool 14 for rotary driven motion.

[0037]The first end 20 of the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| geometric shape | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

| perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com