Temporary adjustable support brace

a technology of support braces and adjustable brackets, which is applied in the direction of building structures, building materials handling, construction, etc., can solve the problems of imposing height limitations, affecting the work efficiency of construction workers, and increasing the labor intensity of existing support systems used in icf tall wall construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

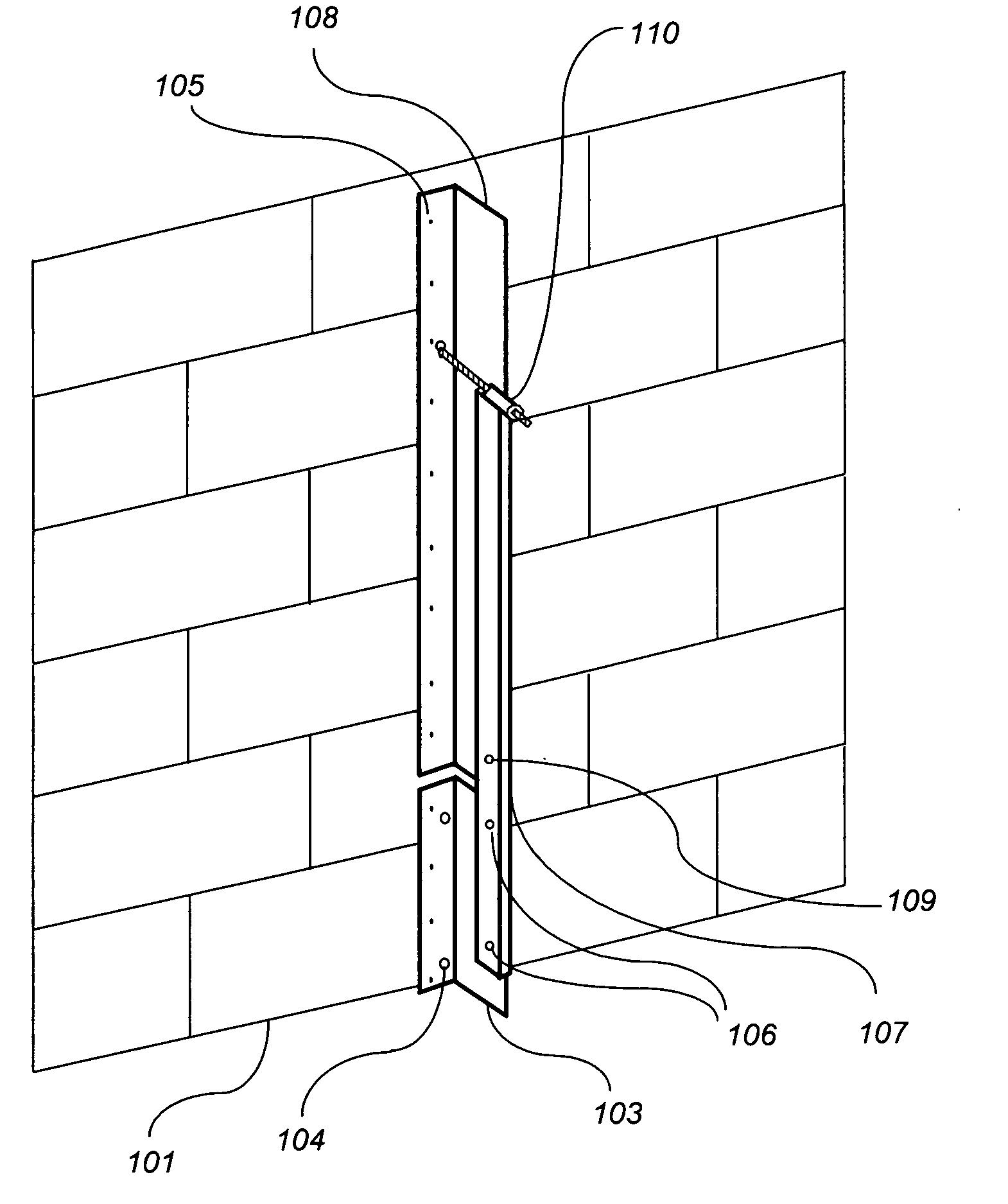

[0011]In the first aspect of the invention, as shown in FIG. 3 a bracing member 103 is disposed vertically and adjacent to the outside face of the first two rows of insulating panel forms 101 with at least one removable horizontal assembly 104 that passes thru the foam panel and will be imbedded in the poured concrete. Prior to placement of the poured concrete the vertical member 103 is temporarily attached to the bridging member end plates 104 of the insulated forms using screws. Typically the first two rows of ICF insulating panel forms are at ground level and therefore vertically plumbed using standard methods for concrete walls. A pourable concrete is then placed within and to the top of the first two rows of the insulating panel forms.

[0012]The next few rows of insulating panel forms are set in place above the lower rows. As shown in FIG. 4 a rigid vertical brace 107 is attached to the lower vertical member 103 at the location 106. The upper vertical member 108 is then attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com