Method of selectively adapting material properties across a rock bit cone

a technology of material properties and rock bits, applied in the field of earthwork tools, can solve the problems of more inserts falling, the body of the rotatable cone may wear, and the hardfacing application may be relatively labor-intensiv

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

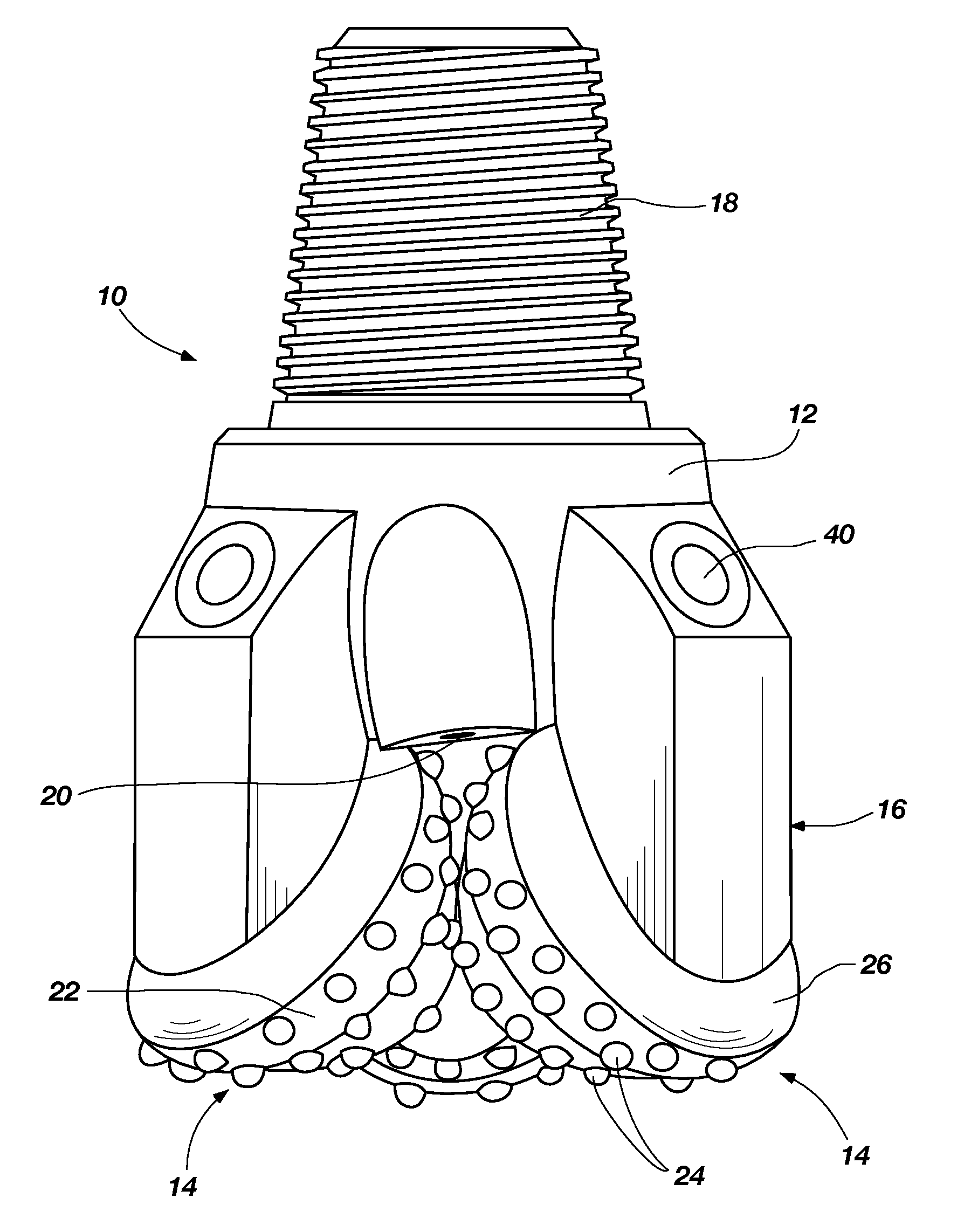

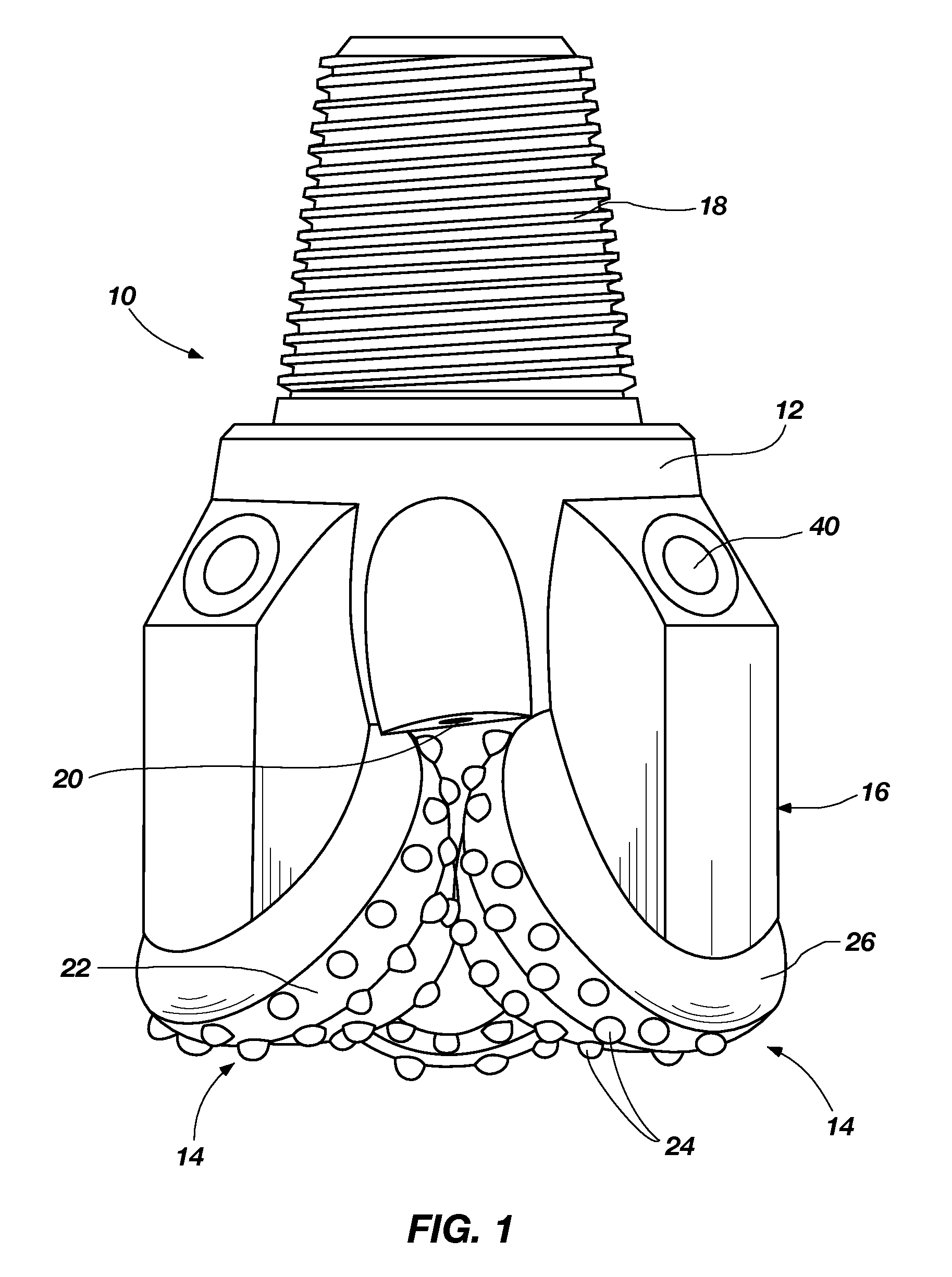

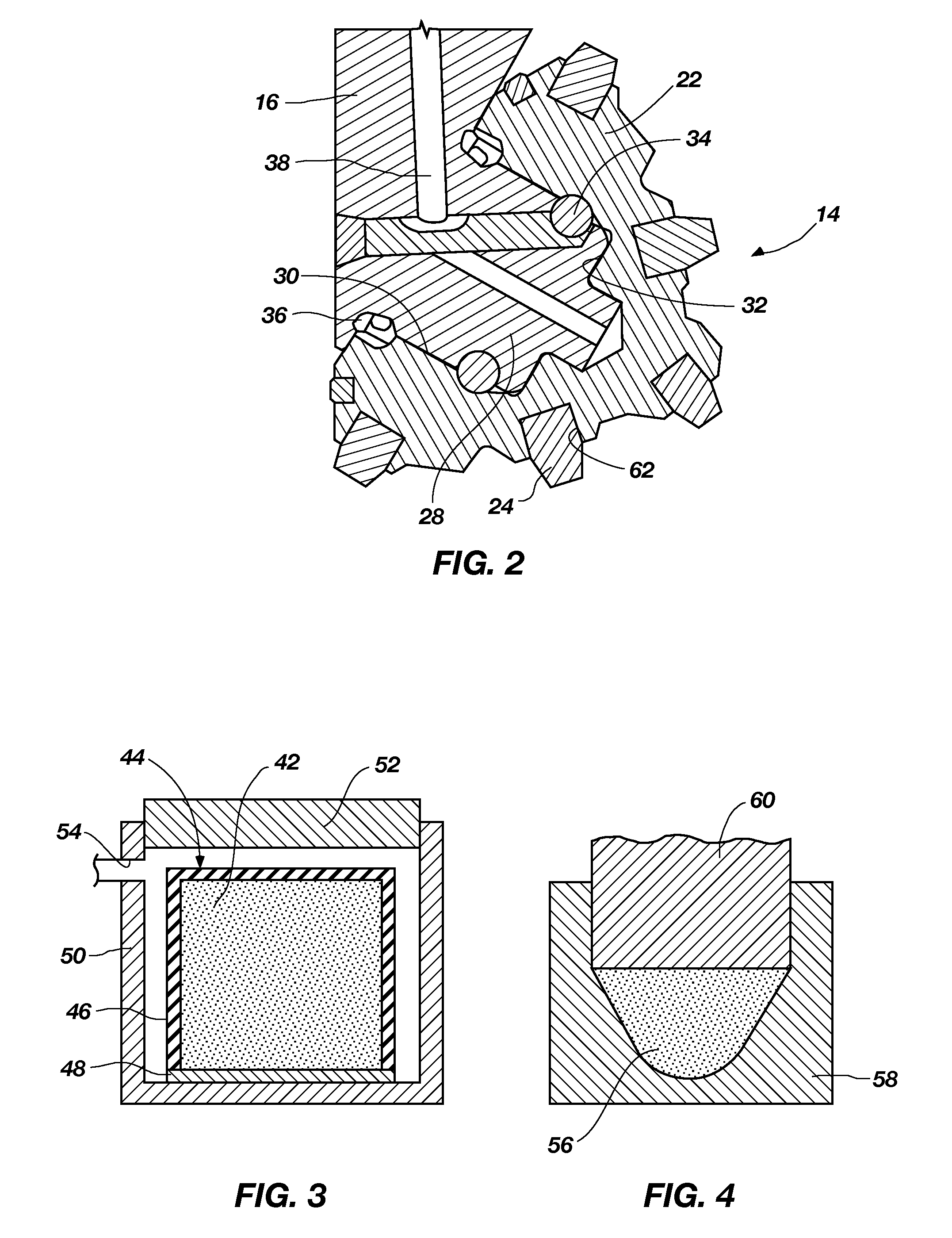

Image

Examples

Embodiment Construction

[0025]The illustrations presented herein are not meant to be actual views of any particular material, apparatus, system, or method, but are merely idealized representations which are employed to describe the present invention. Additionally, elements common between figures may retain the same numerical designation.

[0026]The term “green” as used herein means unsintered.

[0027]The term “green structure” as used herein means an unsintered structure comprising a plurality of discrete particles held together by a binder material.

[0028]The term “brown” as used herein means partially sintered.

[0029]The term “brown structure” as used herein means a partially sintered structure comprising a plurality of particles, at least some of which have partially grown together to provide at least partial bonding between adjacent particles. Brown structures may be formed by partially sintering a green structure.

[0030]The term “sintering” as used herein means densification of a particulate component involv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com