Coupling Device and Method for Enabling Simultaneous Lifting of Two Containers

a technology of coupling device and container, which is applied in the direction of containers, flexible elements, transportation items, etc., can solve the problems of unintentional separation of containers during the lift, damage to items in containers and/or coupling devices, and unfavorable stowage at the site, etc., and achieves the effect of reducing the risk of damage to items in the container and/or the coupling device, and reducing the risk of damag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

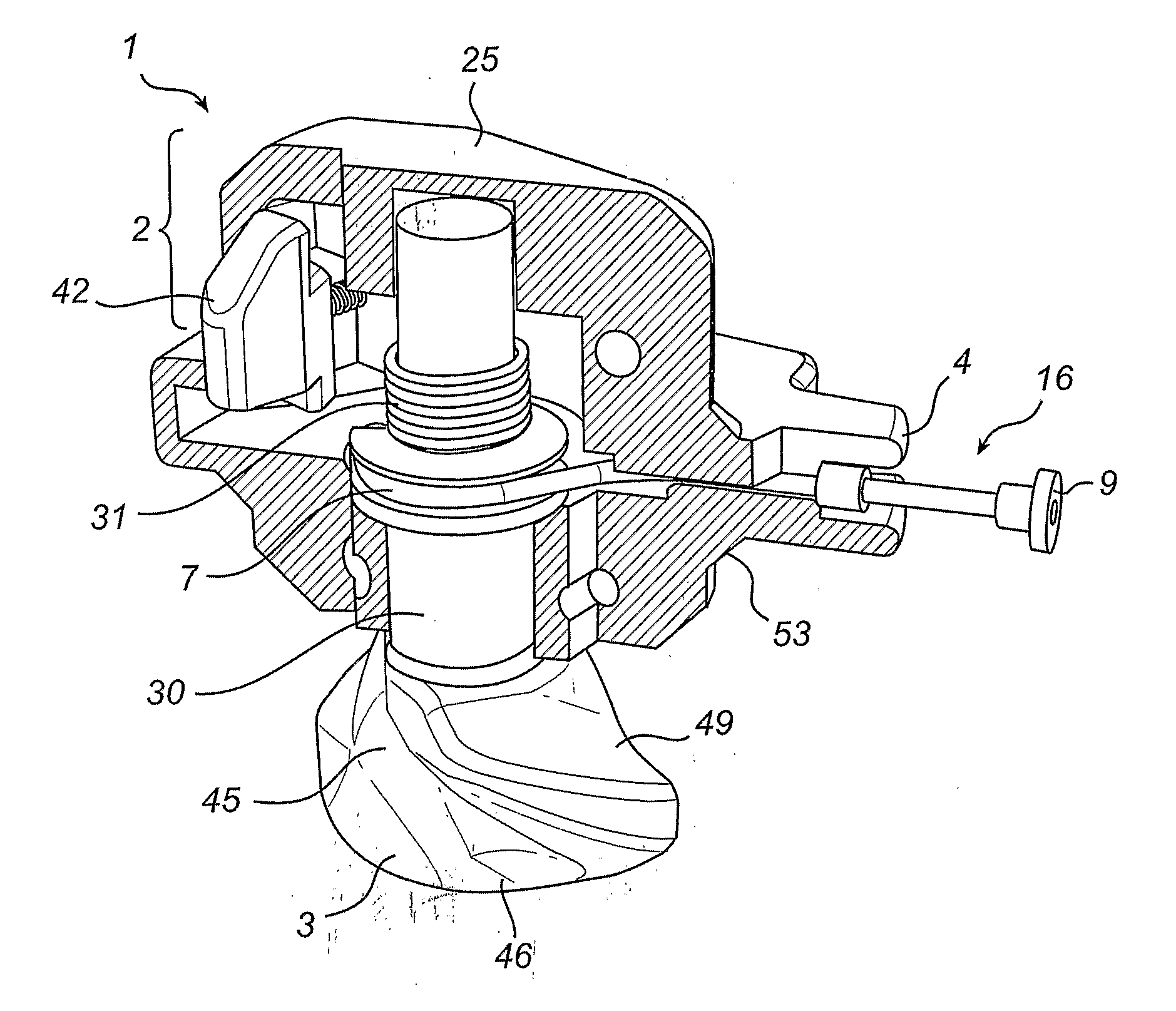

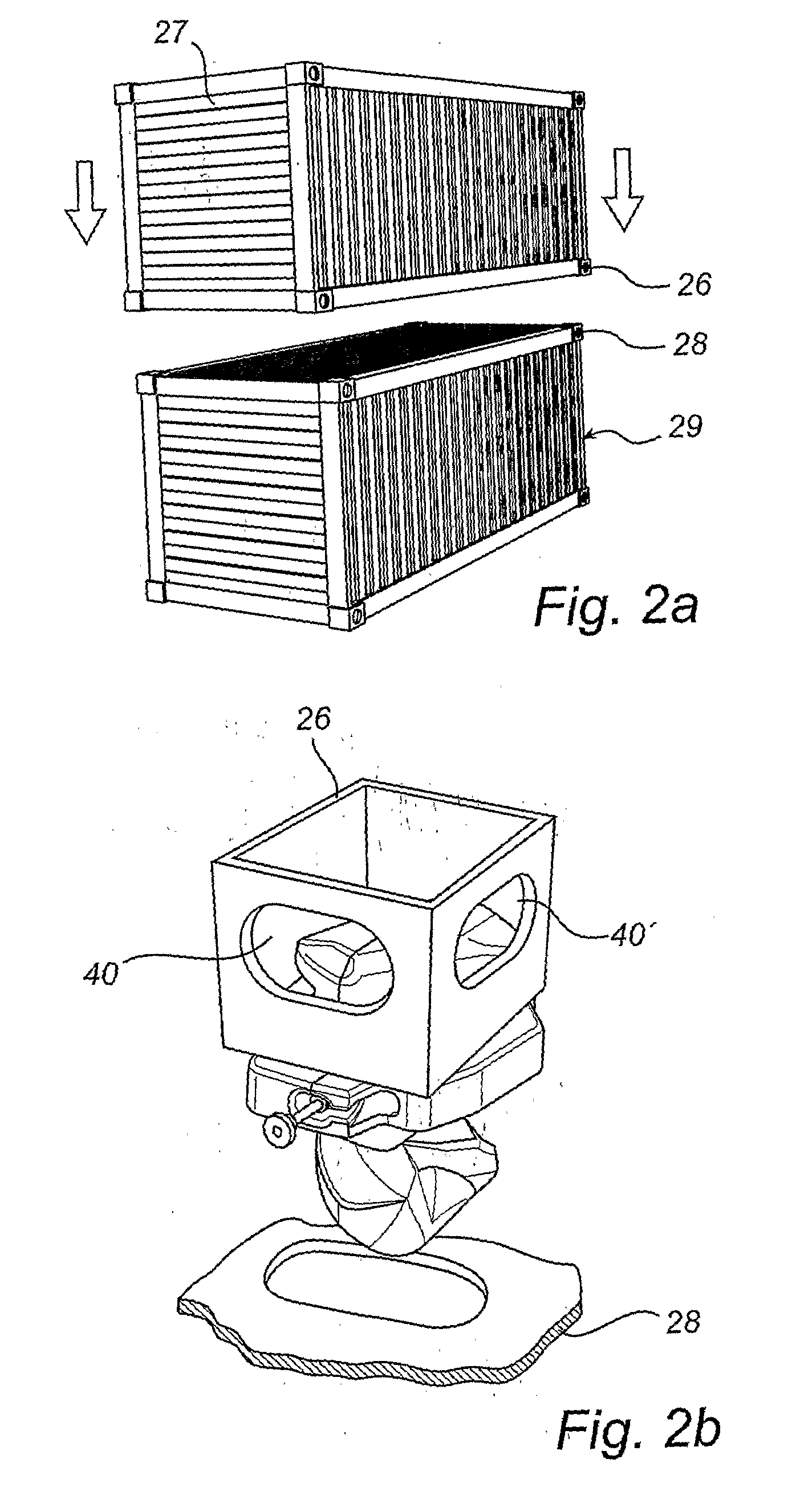

[0080]According to the present invention, shown in FIGS. 1, 3a and 3b, a coupling device 1 comprising a maneuvering means 16 arranged in relation to the second engaging portion 3 may achieve this temporary elimination of the fully automatic feature. As may be seen in FIGS. 1, 3a and 3b, the maneuvering means 16 according to this embodiment comprises a wire 7 and an end knob 9. The wire 7 is attached to the axle 30, which in turn is attached to the second engaging portion 3. As may also be seen in FIGS. 3a and 3b, the section 4 of the housing 25 comprises two interconnected openings 36 and 37, through which the wire 7 may extend and the end knob 9 is positioned outside the housing 25. Due to the interconnection between the two openings 36,37, the maneuvering means 16 may be brought between two different conditions. When the wire extends through the first opening 36, as in FIG. 3a, the coupling device 1 is in its fully automatic condition. The maneuvering means may alternatively be de...

second embodiment

[0084]the present invention is shown in FIGS. 4a to 4b. In this embodiment, the coupling device 1 further comprises a washer 5 arranged in the housing 25. The washer 5 is rotatably arranged in relation to an upper portion 8 of the axle 30. The washer 5 comprises a locking tooth or engagement means 22, and a corresponding locking device 6 is provided in the housing 25.

[0085]The locking device 6, which in this embodiment comprises a lock lug 23, is fixedly arranged in relation to the housing 25 of the coupling device 1. In this embodiment, the lock lug 23 is made as an integral part of the housing 25. The lock lug 23 is positioned in the same central plane as the locking tooth 22 of the washer 5, wherein said central plane extends in a direction perpendicular in relation to the longitudinal axis of the axle portion 8. The arrangement is such that the locking tooth 22 of the washer 5 may be brought into engagement with the lock lug 23 of the locking device 6.

[0086]The upper portion 8 o...

third embodiment

[0094]In FIGS. 5a to 5d the present invention is described. In this embodiment the housing 25 is provided with orientation means, which in this embodiment consists of a projecting nose 34. The projecting nose 34 is connected to, and in this embodiment formed in one piece, with a movable unit 24. The movable unit 24 is movable in a substantially linear path inside the housing 25. Further, the axle 30 is provided with an abutment portion 11 which is arranged above the second engaging portion 3 of the coupling device. The movable unit 24 comprises a recess 32 which allows the abutment portion 11 of the axle 30 to pass the movable unit 24 when the axle 30 rotates due to insertion or removal of the second engaging portion 3 from a corner fitting.

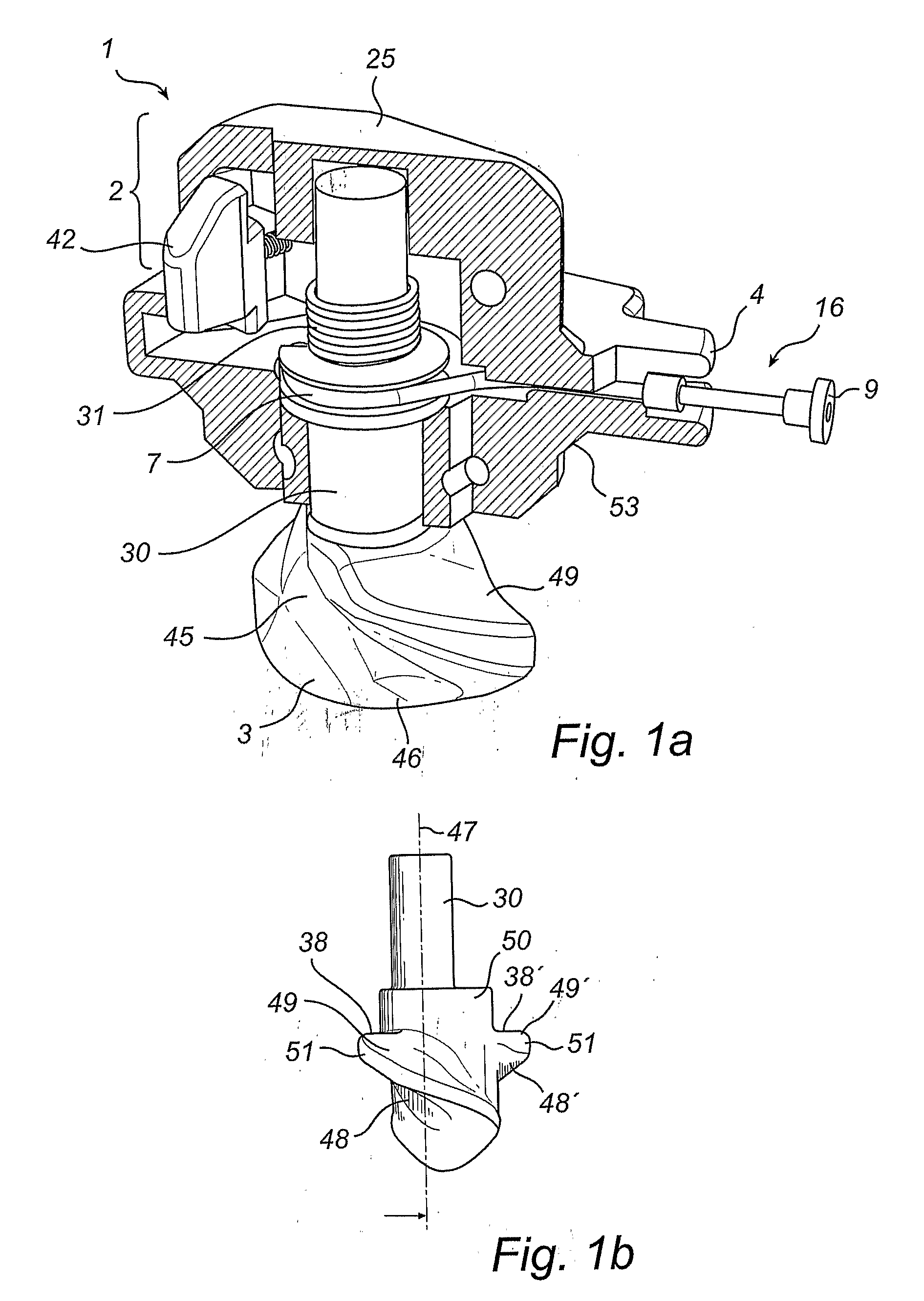

[0095]Corner fittings of an ordinary ISO container usually only have two side openings 40,40′, positioned at adjacent walls, thereby positioning the side openings 40,40′ perpendicularly in relation to each other. Due to the design of the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com