Dry sprinkler system and design methods

a technology of dry sprinklers and sprinklers, applied in the field of dry sprinkler fire protection systems, can solve the problems of dry sprinkler systems, unlike wet systems, present delay, dry sprinkler systems are inferior to wet systems, otherwise impractical,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]A preferred methodology for the design of a dry sprinkler system can be provided in which the dry sprinkler system has an operational performance equivalent to that of a wet system. More specifically, the preferred methodology provides for designing a dry sprinkler fire protection system to protect a storage occupancy having a defined ceiling height to store a commodity of a defined commodity class, storage configuration and storage height. The dry sprinkler system is preferably configured to hydraulically perform the same as a wet system configured to protect a substantially similar storage occupancy and commodity arrangement. Accordingly, the preferred method of dry sprinkler design is based upon the use of wet sprinkler performance as a bench mark.

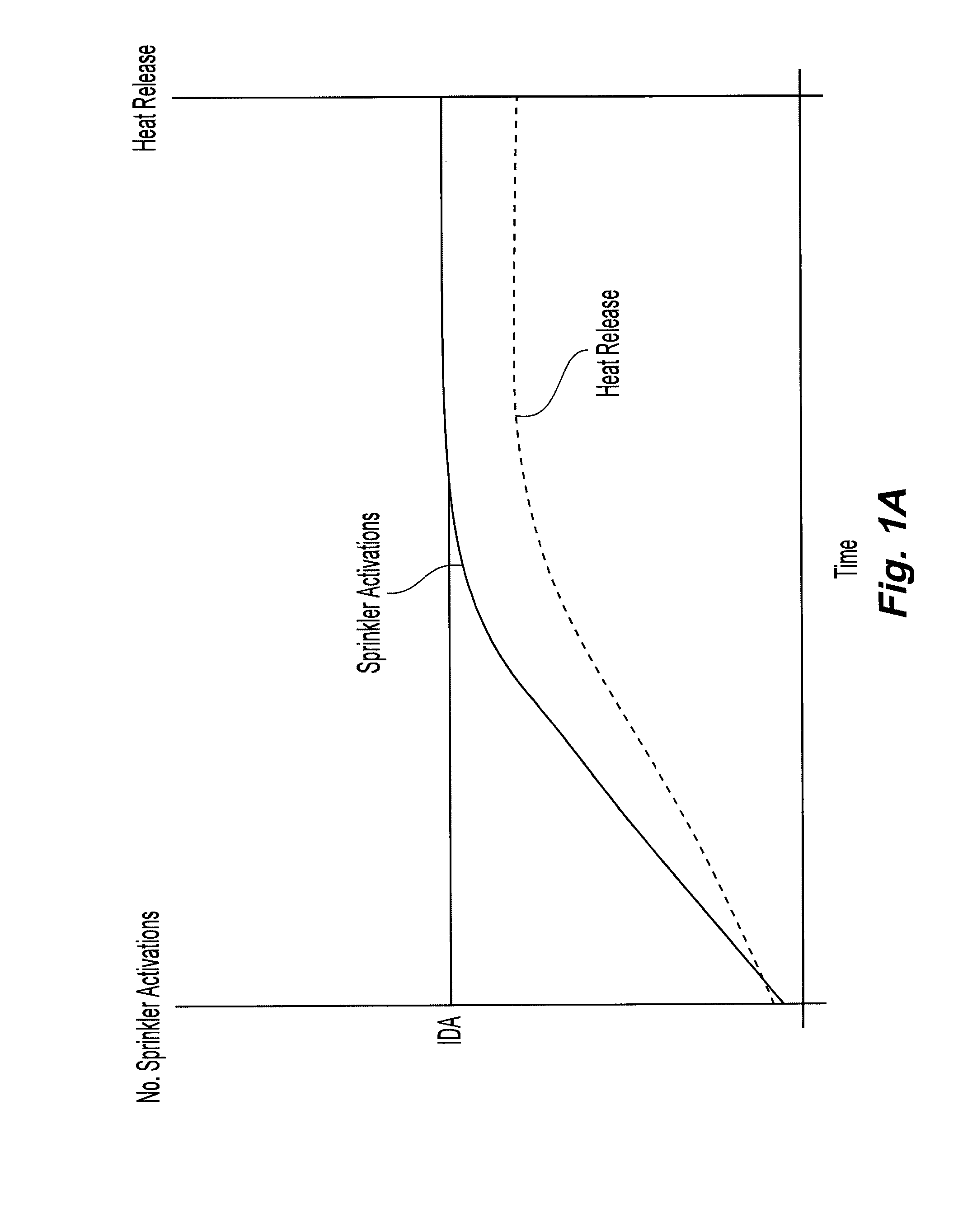

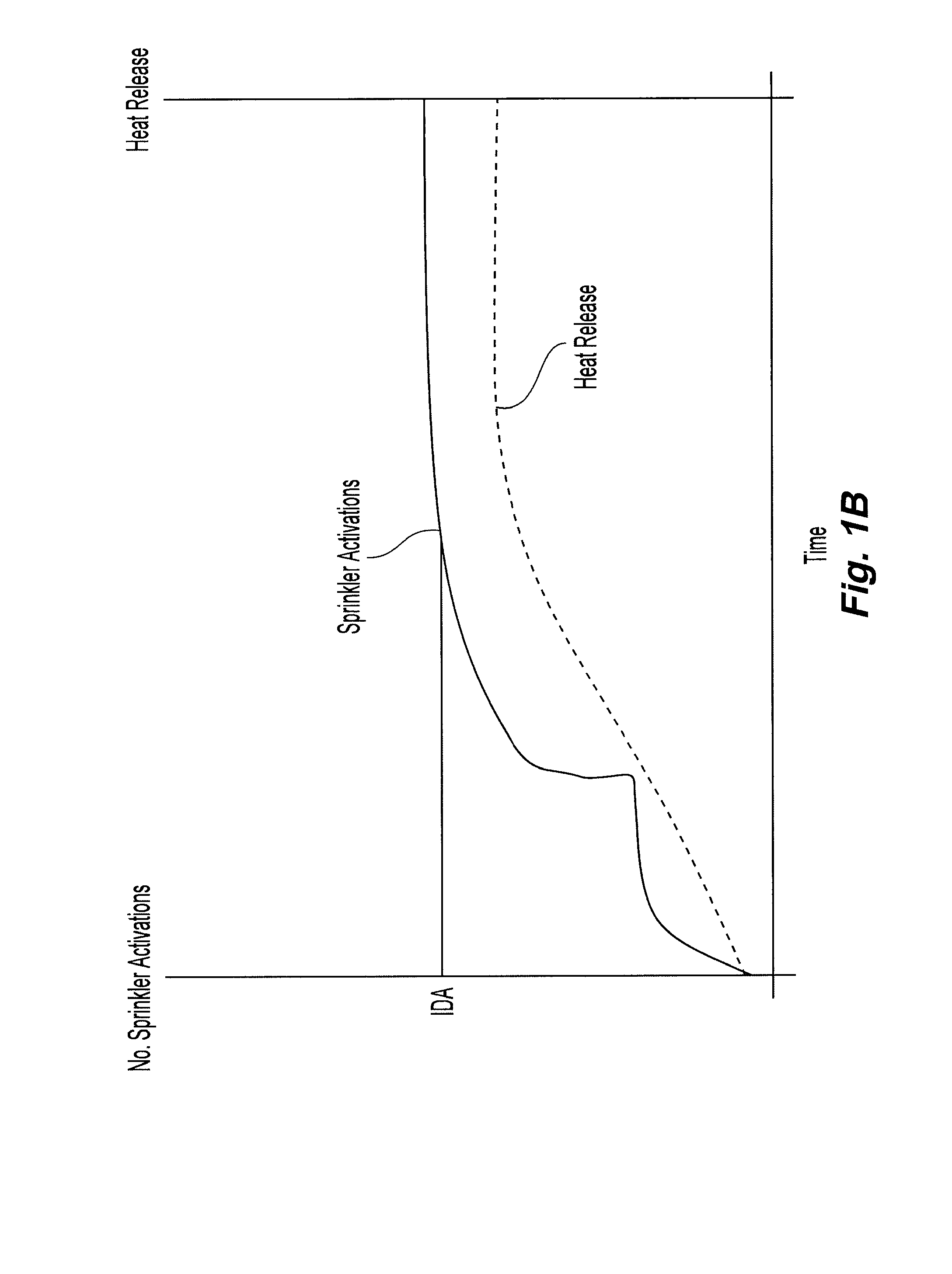

[0036]In particular, the preferred design methodology relies upon a presumption about wet sprinkler performance. It is believed that a wet sprinkler system has an inherent design area (IDA) which is defined by a total number of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com