Charcoal Starting Device and Method

a starting device and charcoal technology, applied in the direction of firelighters, household stoves or ranges, solid fuels, etc., can solve the problems of inability to guarantee rapid coal formation, poor combustion effect, and general dusty charcoal, and achieve the effect of facilitating air ingress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

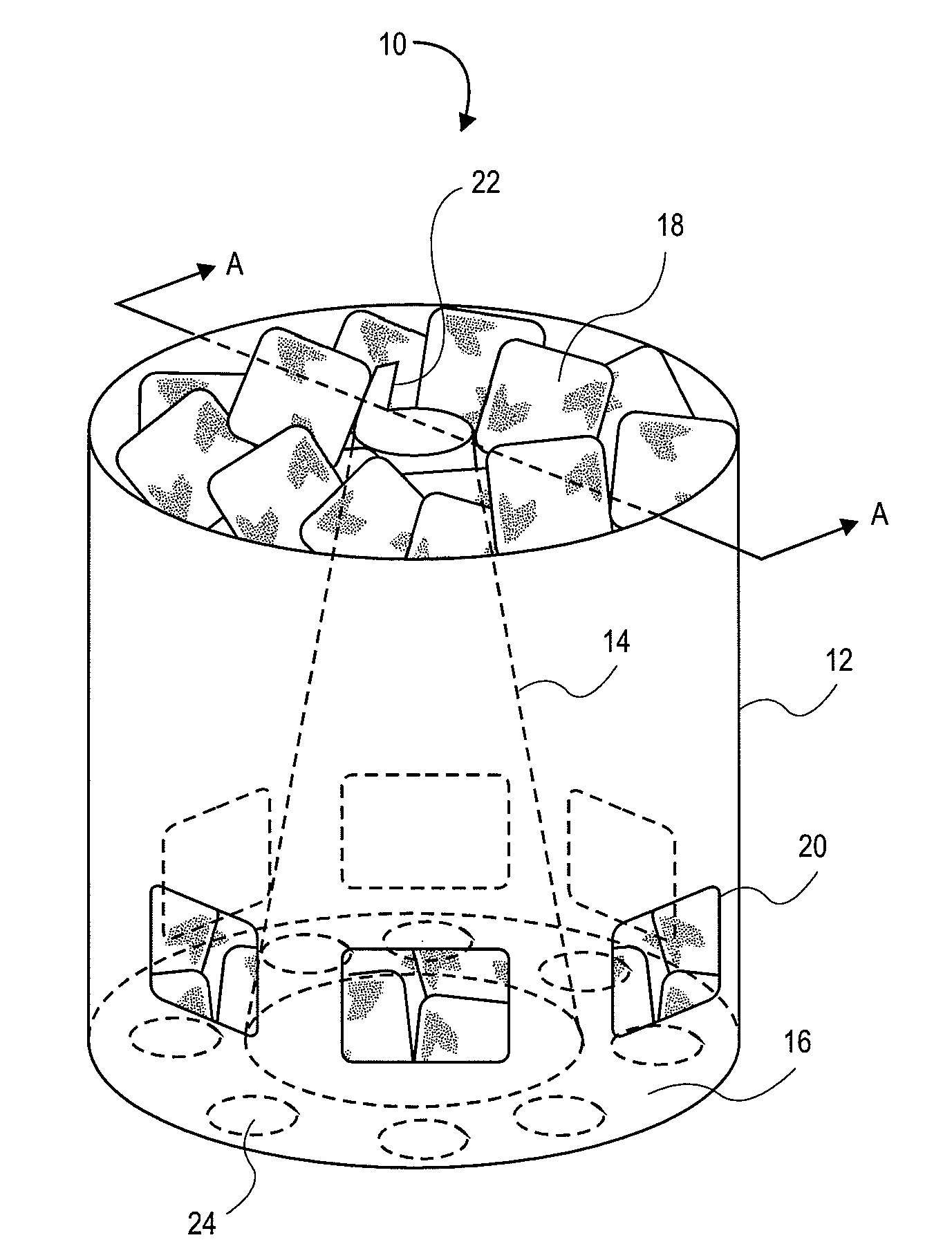

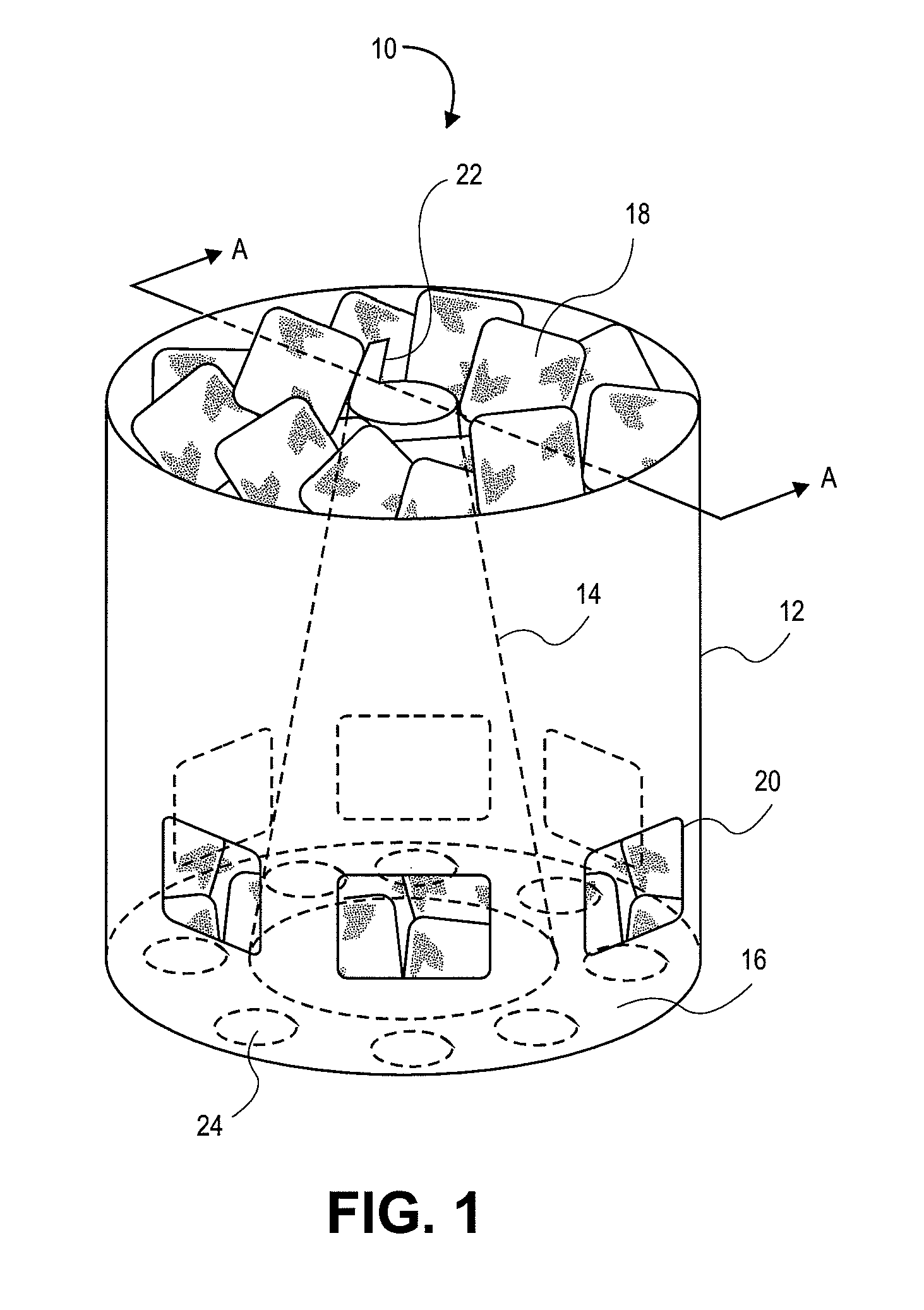

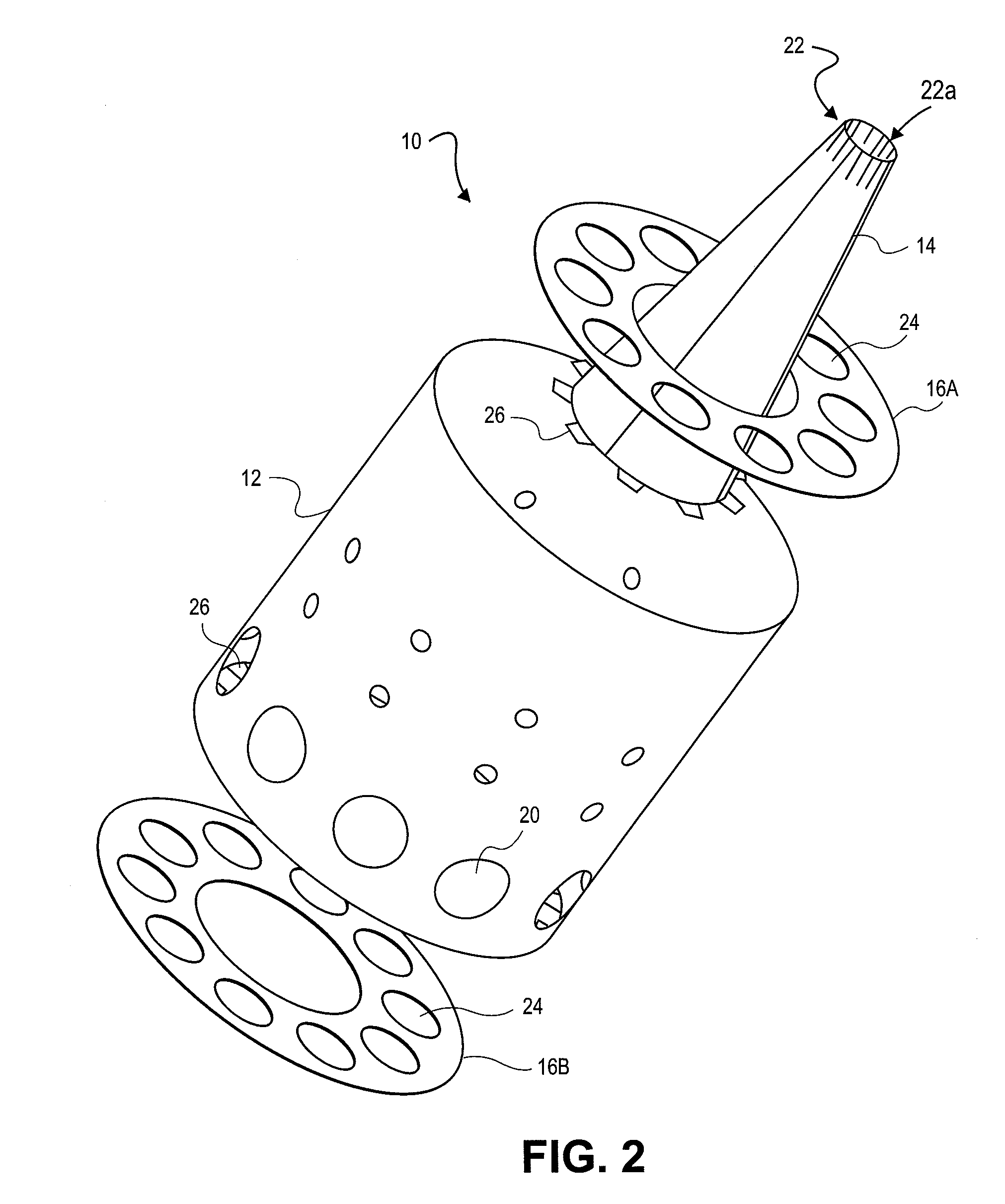

[0018]The present invention provides, in some embodiments, a charcoal starting or igniting device and a method of fabricating the charcoal igniting device. In general, the charcoal igniting device includes an envelope or container configured to retain a supply of charcoal. For the purpose of this disclosure, an envelope is defined as a structure to enclose or partially enclose a space, volume, or item. This envelope includes a fiber-based sheet stock such as, for example, fiberboard, corrugated fiberboard, and the like. For the purpose of this disclosure, the term, “fiberboard” is defined as at least including, for example, paper, paperboard, cardboard, corrugated cardboard, cellulosic, and / or resinous material which is similar in character to fiberboard, and which is manipulated in the same or similar manner as fiberboard. This includes any suitable material capable of being folded from a blank. In this regard, the term “blank” refers to at least a piece or unit of fiberboard that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com