Modular hybrid drill bit

a hybrid drill bit and module technology, applied in drill bits, earth drilling and mining, cutting machines, etc., can solve the problems of cutter stopping rotation, bearing failure, rolling cutter bit failure,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

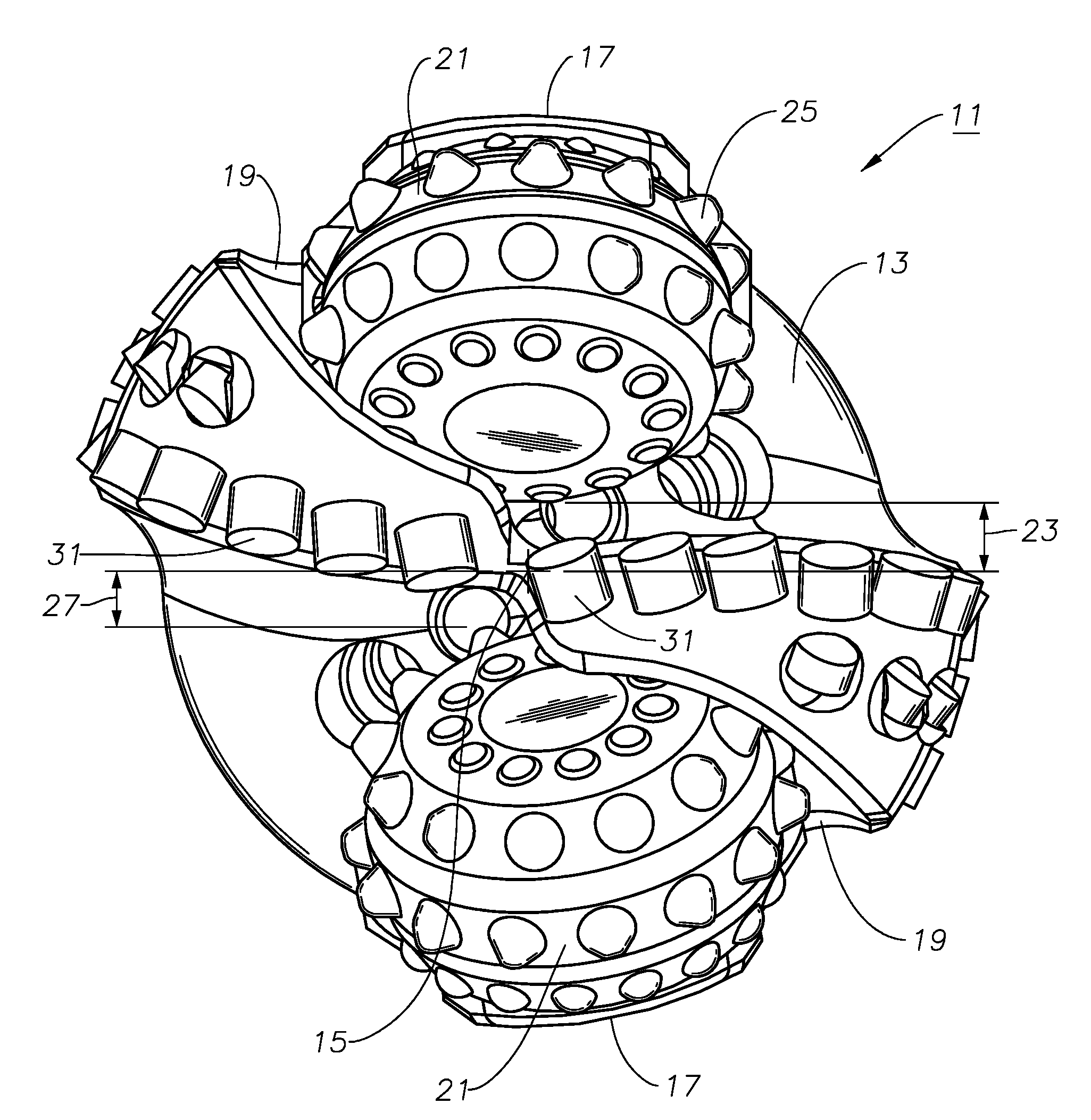

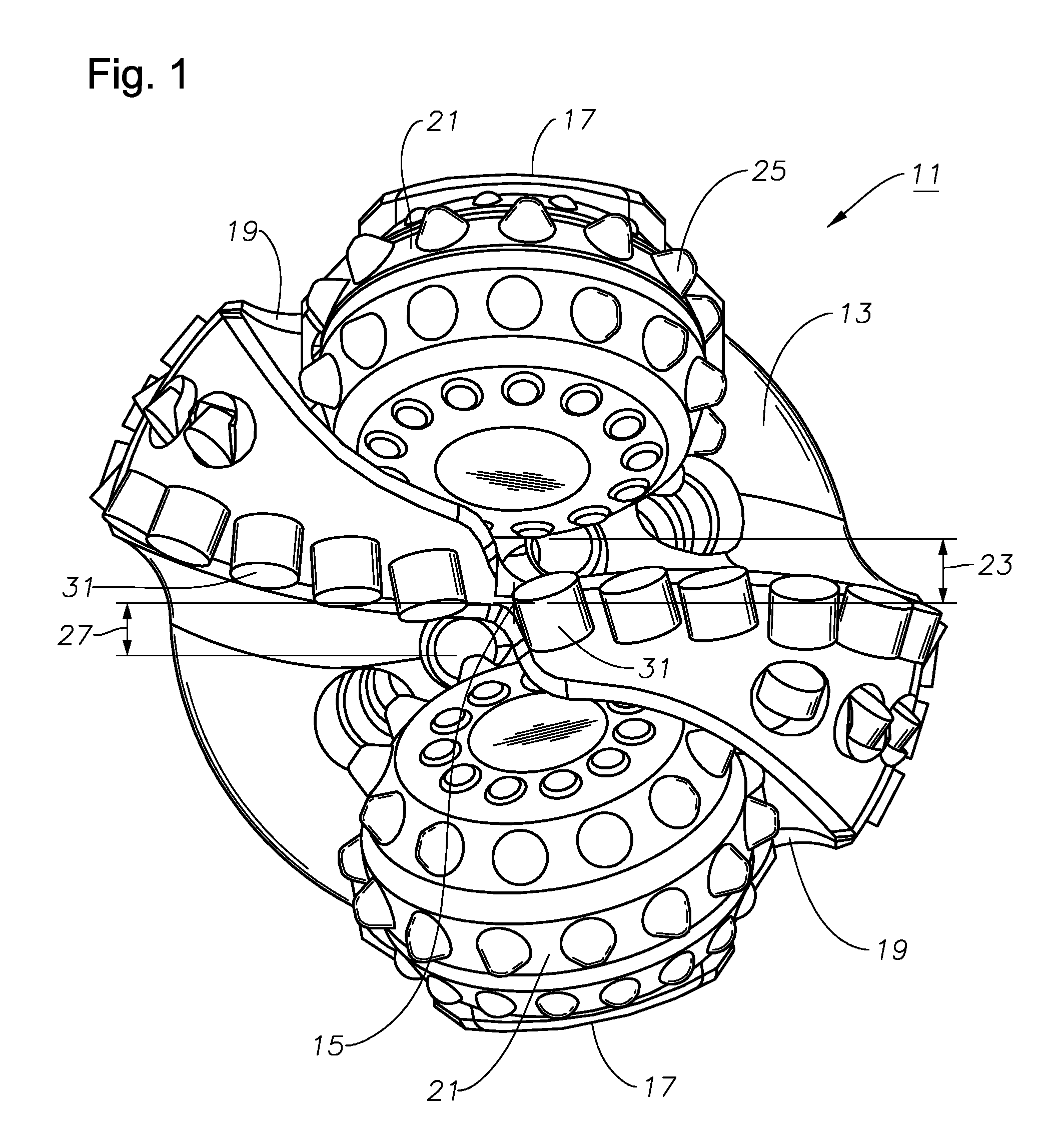

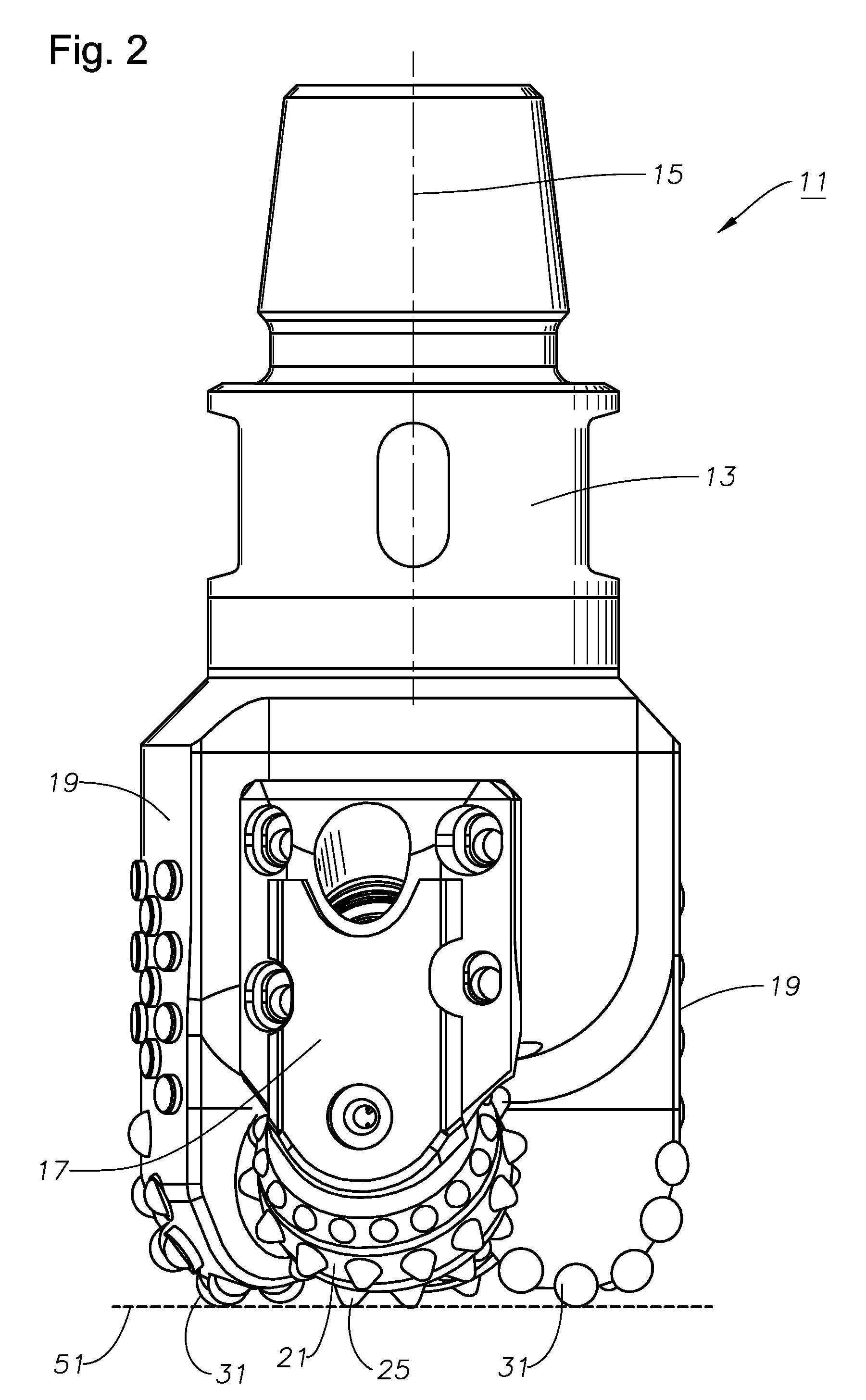

[0021]Referring to FIGS. 1-2, an illustrative embodiment of a modular hybrid earth-boring drill bit is disclosed. The bit 11 comprises a bit body 13 having an axis 15 that defines an axial center of the bit body 13. A plurality (e.g., two shown) of bit legs or heads 17 extend from the bit body 13 in the axial direction. The bit body 13 also has a plurality (e.g., also two shown) of fixed blades 19 that extend in the axial direction. The number of each of legs 17 and fixed blades 19 is at least one but may be more than two (as in the case of the embodiment illustrated in FIG. 3). In one embodiment, the centers of the legs 17 and fixed blades 19 are symmetrically spaced apart from each other about the axis 15 in an alternating configuration.

[0022]Rolling cutters 21 are mounted to respective ones of the bit legs 17. Each of the rolling cutters 21 is shaped and located such that every surface of the rolling cutters 21 is radially spaced apart from the axial center 15 (FIG. 2) by a minim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| included angle | aaaaa | aaaaa |

| included angle | aaaaa | aaaaa |

| acute angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com