Hard surface cleaner

a technology of fluid cleaning and hard surface, which is applied in the direction of vacuum cleaners, carpet cleaners, domestic applications, etc., can solve the problems of wet floor surface, inability to extract all of the fluid, damage to the floor surface,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]For a better understanding of the present invention, reference may be had to the following detailed description taken in conjunction with the appended claims and the accompanying drawings.

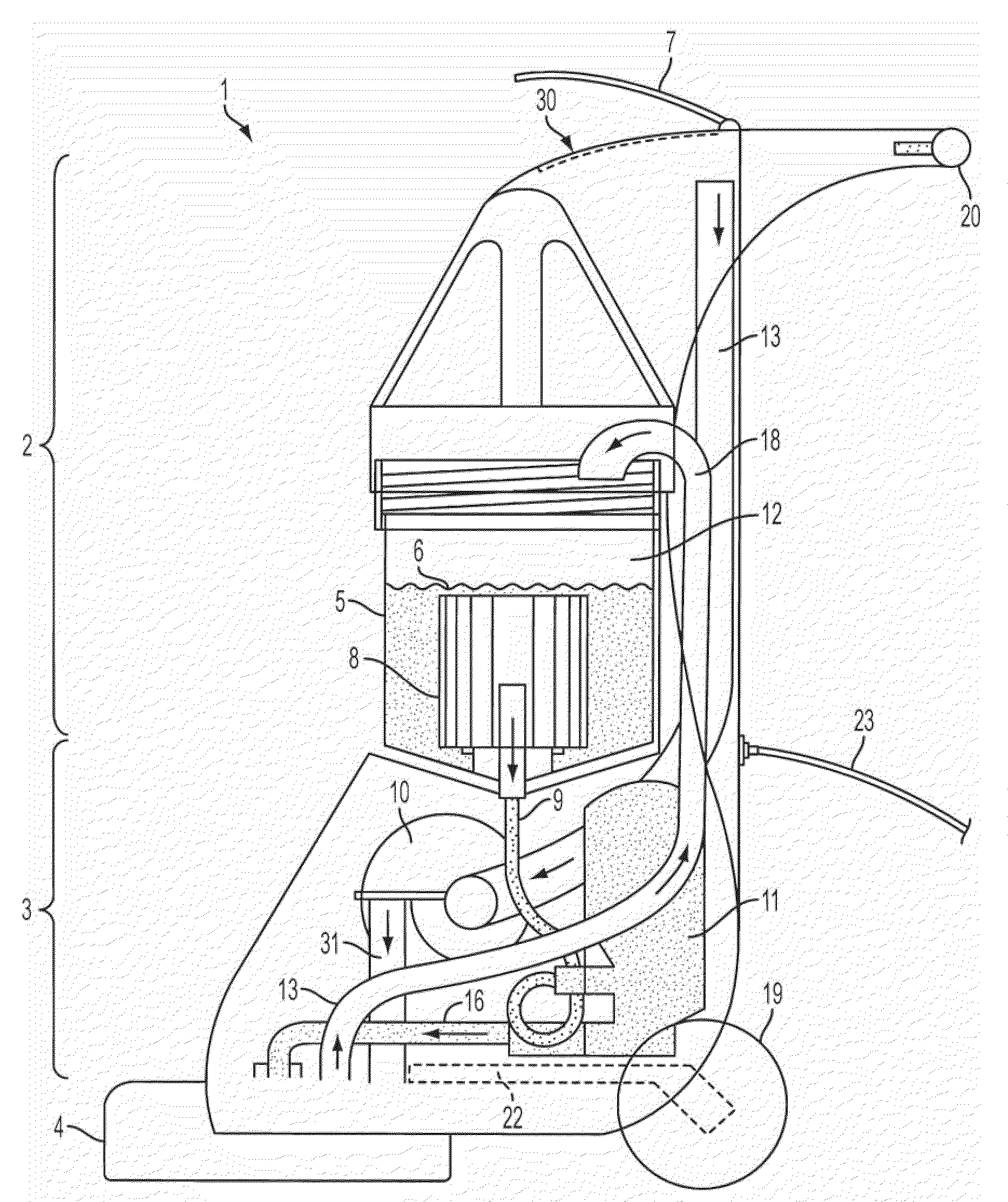

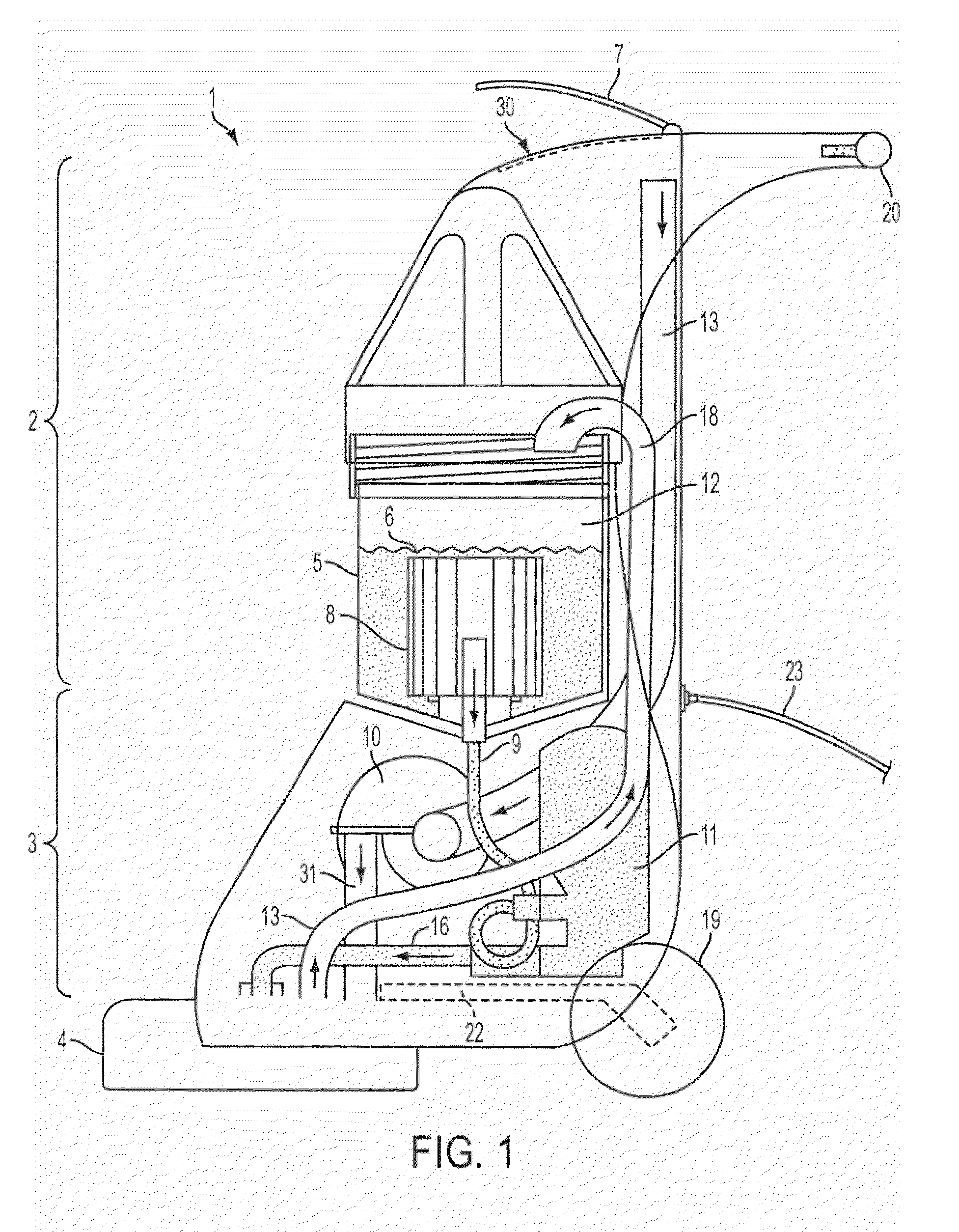

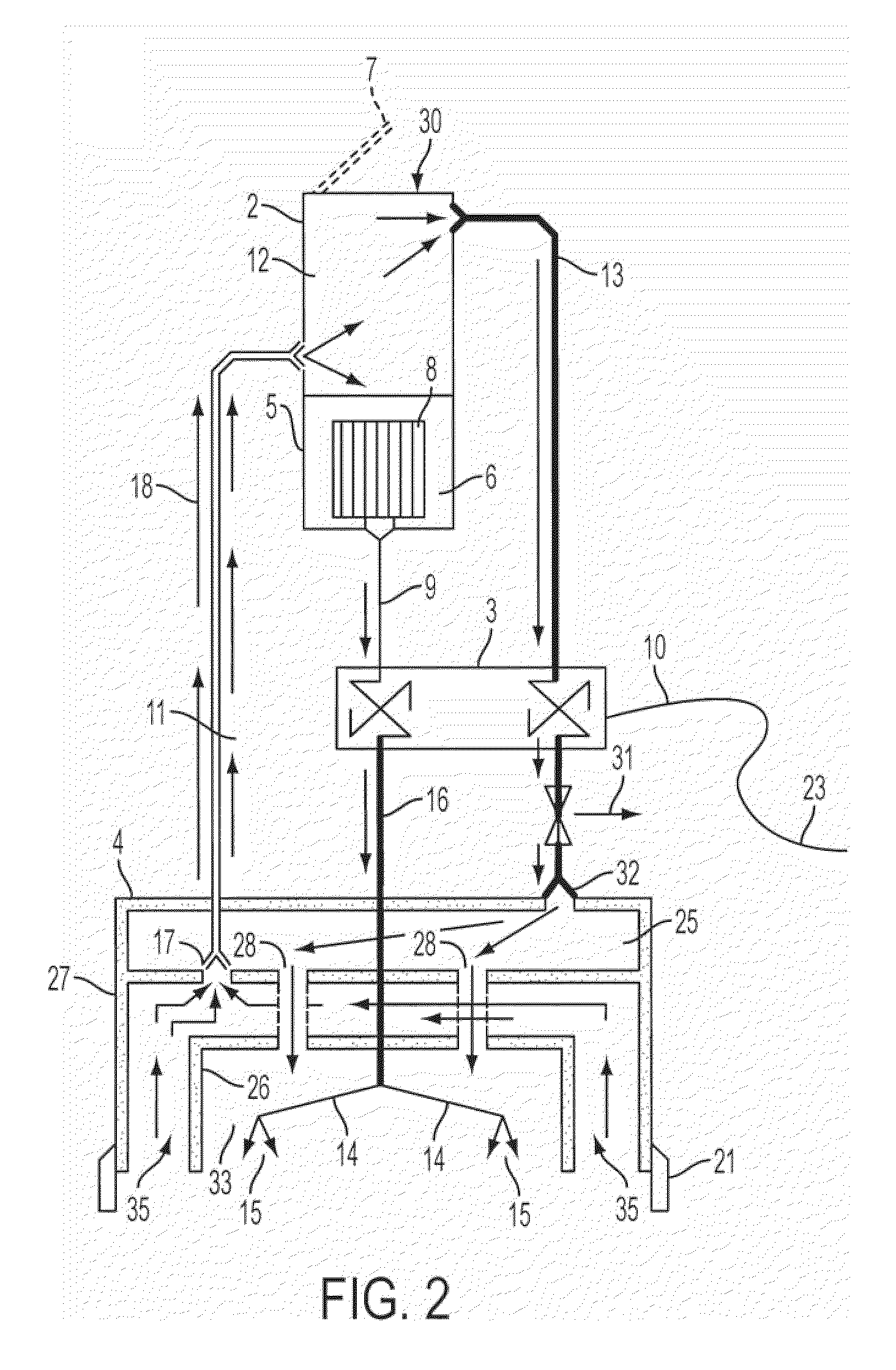

[0027]The present invention is a portable, self-contained hard surface floor cleaning apparatus 1 that operates simultaneously as a water pressure cleaning device and a wet-dry vacuum. The apparatus is suitable for use in both indoor and outdoor spaces on a variety of hard surface floor coverings such as tile, grout, epoxy and stained concrete. The apparatus is comprised of a tank portion 2, a power portion 3 and a cleaning head portion 4 that may optionally be detachable.

[0028]FIG. 1 depicts an embodiment of the present invention. The tank portion 2 is comprised of a tank 5 that is preferably positioned upright above the power portion 3 wherein the tank's volume is partially filled with a suitable cleaning fluid 6 that is fed through a supply line 9 to the power portion 3 of the apparatus. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com