Hose clamp removal and installation tool

a technology of installation tool and hose clamp, which is applied in the direction of metal-working hand tools, metal-working wire tools, metal-working apparatus, etc., can solve the problems that the design of such tools may not provide desired benefits or advantages, and achieve the effect of facilitating the positioning of tangs or ends, preventing slippage of the band hose clamp, and facilitating the alignment of the hose clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

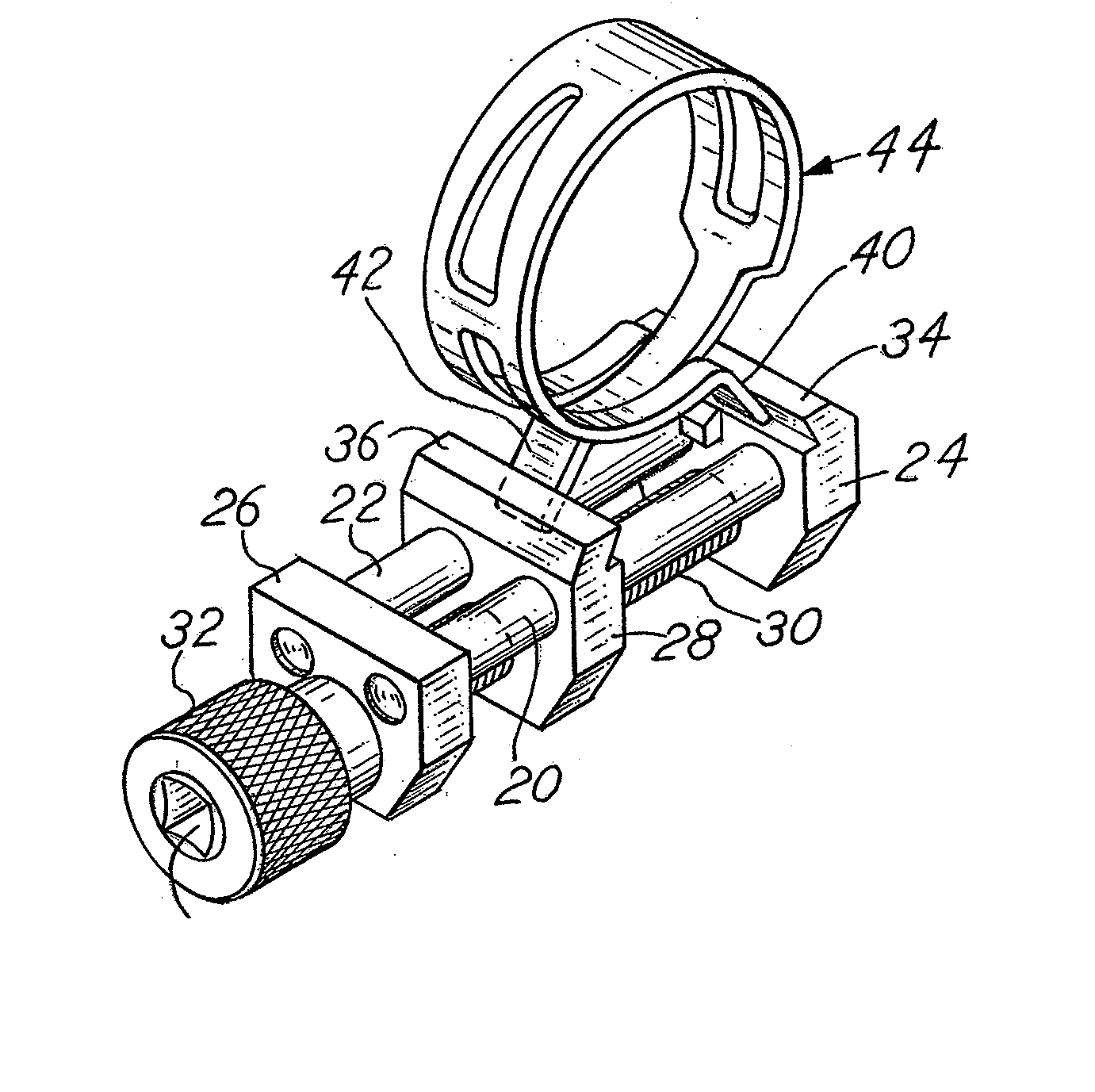

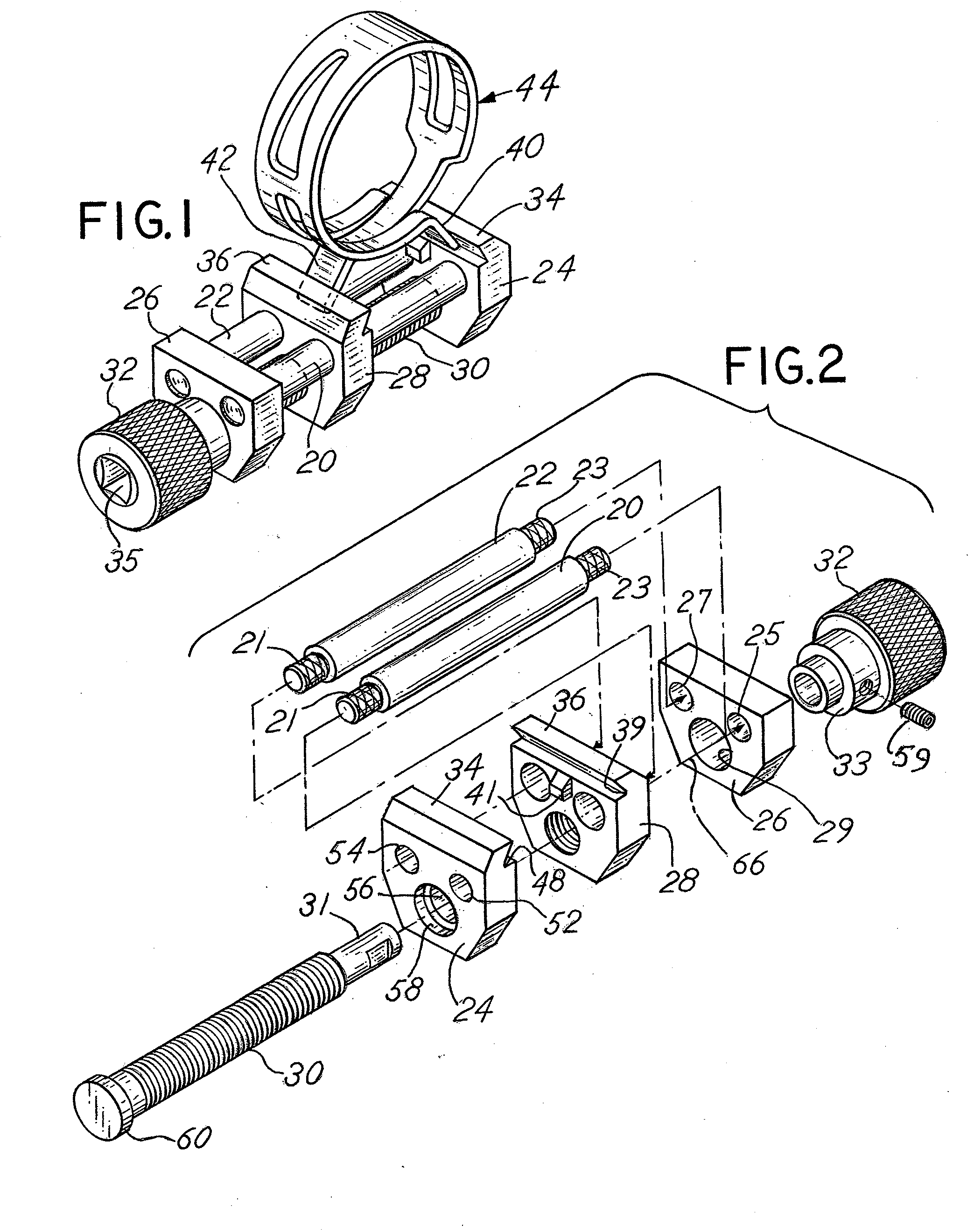

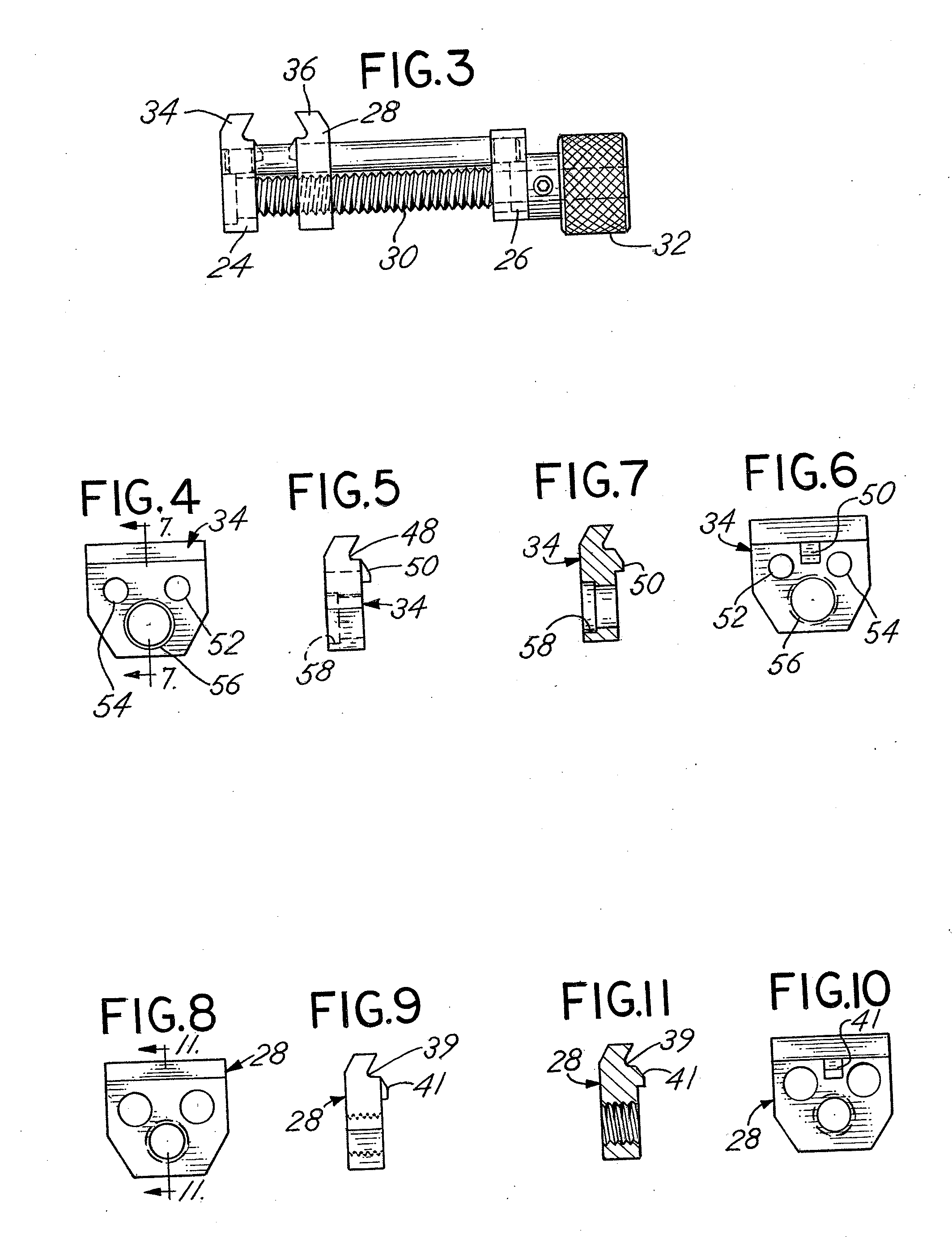

[0051]Referring to FIGS. 1-17, the hose clamp tool of the invention is comprised of a multiple number of component parts which are assembled as described herein. Those parts are depicted in an exploded isometric view (FIG. 2) and can be summarized as follows. The tool includes first and second, parallel generally cylindrical rails 20 and 22. The first and second rails 20, 22 are designed to connect a fixed, spaced first plate 24 to a second or parallel base plate 26 which is also affixed to and spaced from the first or fixed plate 24. A parallel sliding plate 28 is slidably mounted on the first and second rails 20 and 22 and is threadably engaged by a rotatable, threaded rod 30 journaled through first plate 24 and second or base plate 26. Rod 30 is situated beneath rails 20, 22 with engagement elements or opposed jaws 34, 36 on opposed jaws 24, 28, respectively, situated above and along the upper side of the rails 20, 22. Rod 30 may be rotated by means of attached knob 32 to move th...

second embodiment

[0065]Alternatively, a band type wire clamp, such as illustrated in FIG. 1, may still be utilized and compressed using the second embodiment compression tool inasmuch as the cross channels such as the channels 39 and 48 are maintained in the embodiment of FIGS. 18-34. As a consequence, the construction of the embodiment of FIGS. 18-34 is useful with both a band type hose clamp as well as a wire type hose clamp and may be used in a manner which provides for avoidance of torqueing or twisting the hose clamp as it is removed regardless of the type of the clamp that is being used. The channels 102 and 104, of course, may be sized so as to be cooperative with multiple sizes or gauge of wire associated with a wire or ring type clamp 144. Each channel 102, 104 subtends or generally bottoms against a surface, such as the surface 110, of the slot 39 subtending the channel 104, and the surface 112 of the slot 48 subtending the channel 102. The surfaces 112 and 110 comprise a means for limitin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| circumference | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com