Device Support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

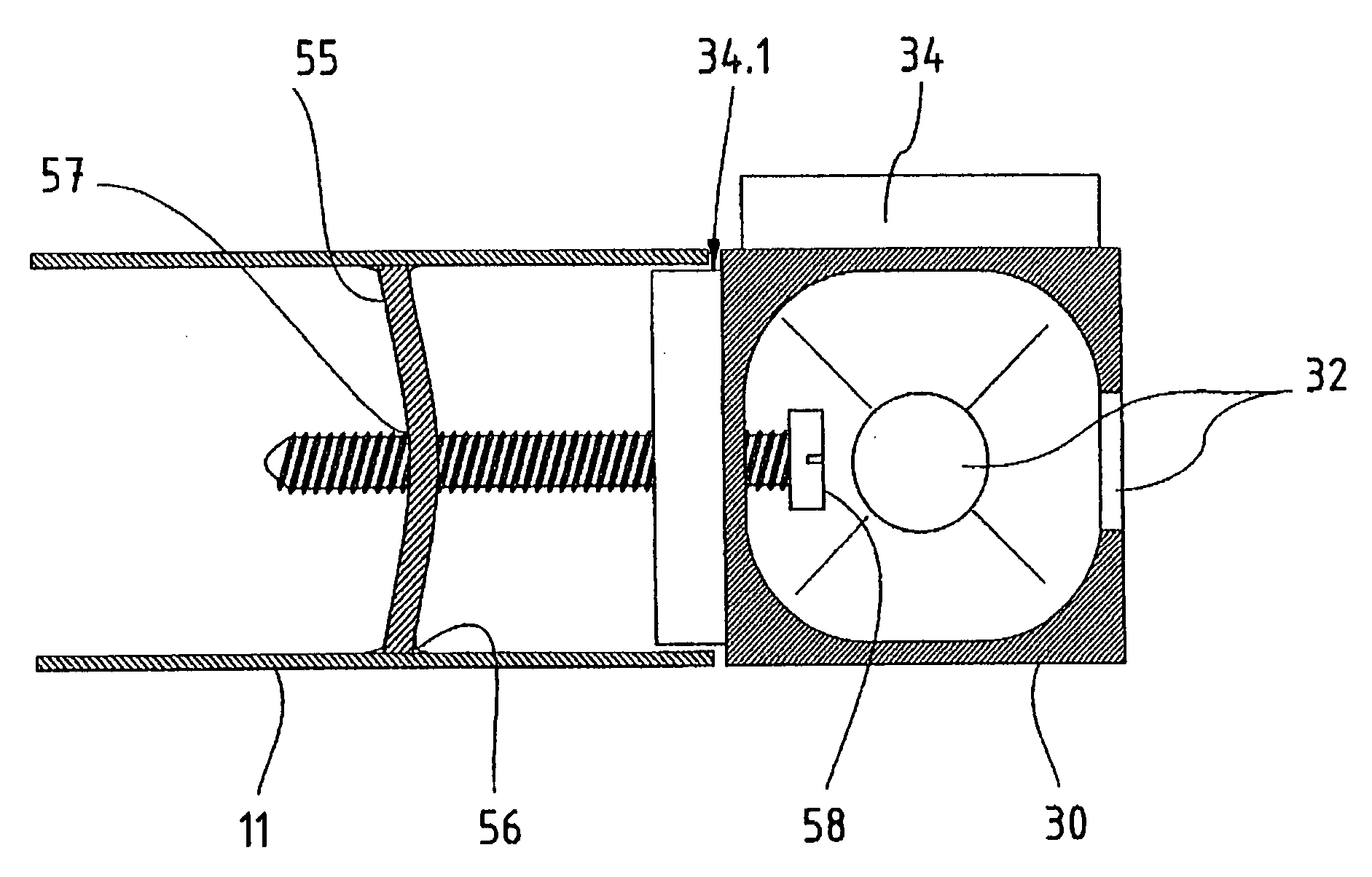

[0024]The preferred embodiments of the present invention will now be described with reference to FIGS. 1-6 of the drawings. Identical elements in the various figures are designated with the same reference numerals.

[0025]FIG. 1 shows a first cabinet frame 10 for a device support with hollow profiles 11, 12, 13 subject to the invention as well as corner connector elements 30. The cabinet frame includes a total of eight corner connector elements 30 as well as twelve hollow profiles. The corner connector elements 30 are connected with the profiles via screw connections. Because a spatial structure is being formed, the device support will be called a device cabinet hereafter.

[0026]FIG. 2 shows a second cuboidal cabinet frame 20 with a rectangular base frame 24, where the four corners are each connected with a vertically arranged hollow profile 22 of the cuboidal cabinet frame 20 via a weld or screw connection. Corner connector elements 30 are arranged at the four upper corners of the cub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com