Paint ball loader housing

a paint ball and loader technology, applied in the field of paint ball loader systems, can solve the problems of deficiency of paint ball loader housings which come with paint ball gun loader systems in one or more of these characteristics, and the housing can break, so as to improve the capacity, improve the loader system, and improve the loader. the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

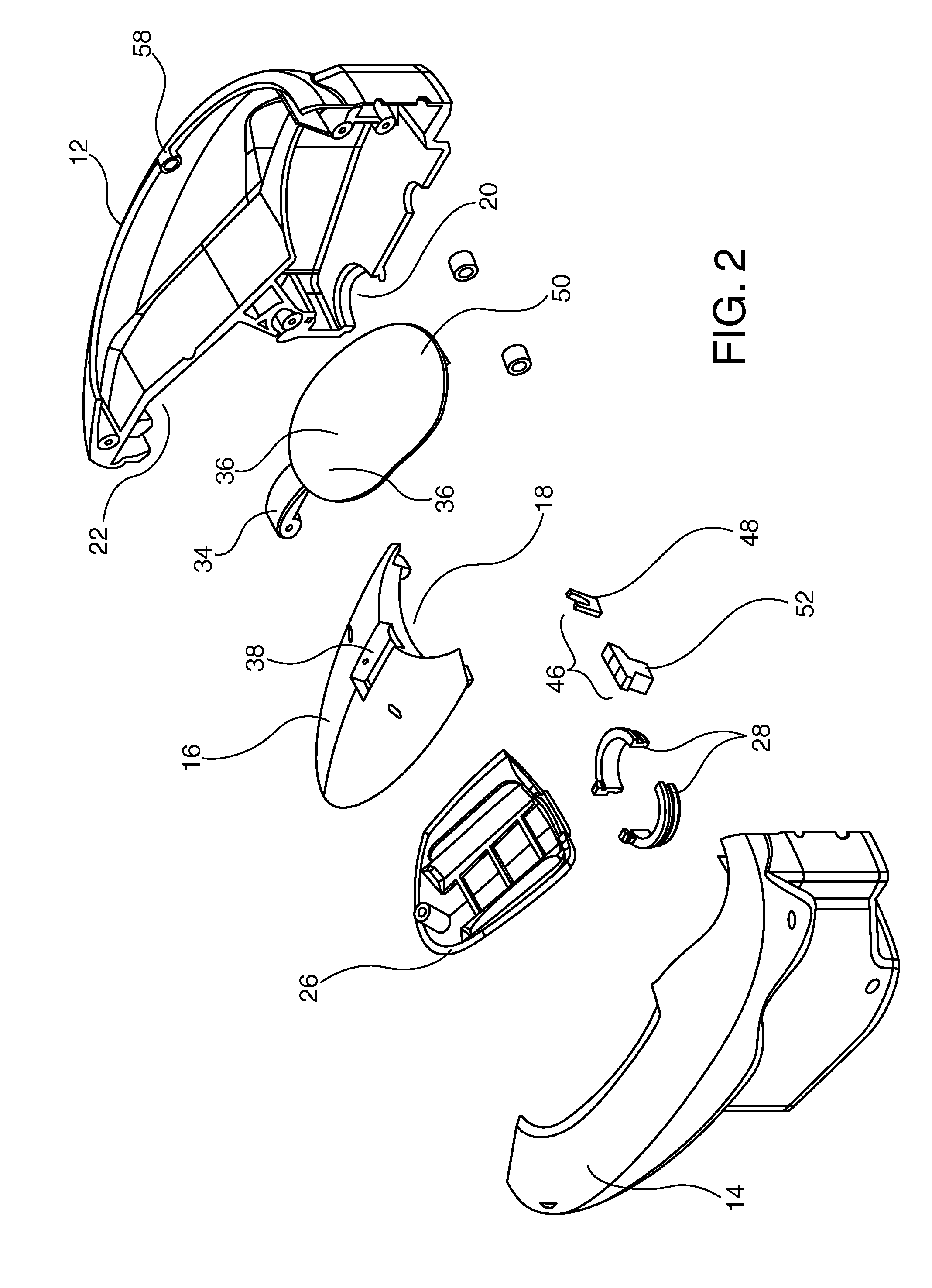

[0020]FIG. 2 illustrates the invention wherein the means for removably affixing the paint ball loader housing to a paint ball loader includes a feed neck collar adapter 28 removably affixed within the bottom outlet 20. The feed neck collar adapter 28 further acts as a feed neck reinforcement in particular loader systems. Also illustrated is an embodiment of the invention wherein the means for pivotally affixing the top filler opening lid 24 to the top portion 16 is a hinge mechanism which allows the lid 24 and top portion 16 to be removed as a single piece, and which remains intact and affixed to the lid 24 when disengaged from the top portion 16. The hinge mechanism includes a hinge extension 34 extending from a first end 36 of the top filler opening lid 24, a hinge trough 38 in the top portion 16, with the hinge trough 38 sized to receive the hinge extension 34 therein, with the hinge extension 34 pivotally retained within the hinge trough 38 such that the top filler opening lid 2...

second embodiment

[0022]FIG. 3 illustrates the invention wherein the means for removably affixing the paint ball loader housing to a paint ball loader includes a tray adapter 30 removably affixed within the generally oval housing (between the right side shell housing 12 and the left side shell housing 14) adjacent the bottom outlet 20. The tray adapter 30 can further include a feed neck reinforcement. Also illustrated is an embodiment of the invention wherein the means for pivotally affixing the top filler opening lid 24 to the top portion 16 is a hinge mechanism having a hinge extension 34 extending from a first end 36 of the top filler opening lid 24, a hinge trough 38 in the top portion 16, with the hinge trough 38 sized to receive the hinge extension 34 therein, with the hinge extension 34 pivotally retained within the hinge trough 38 such that the top filler opening lid 24 is pivotable between a closed position and an open position. The lid 24 is retained in a closed position by a one touch plun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com