Portable magnetic toy construction kit

a technology of magnetic toy and construction kit, which is applied in the field of toy construction kit, can solve the problems of inability to build large structures that maintain sufficient stability and complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

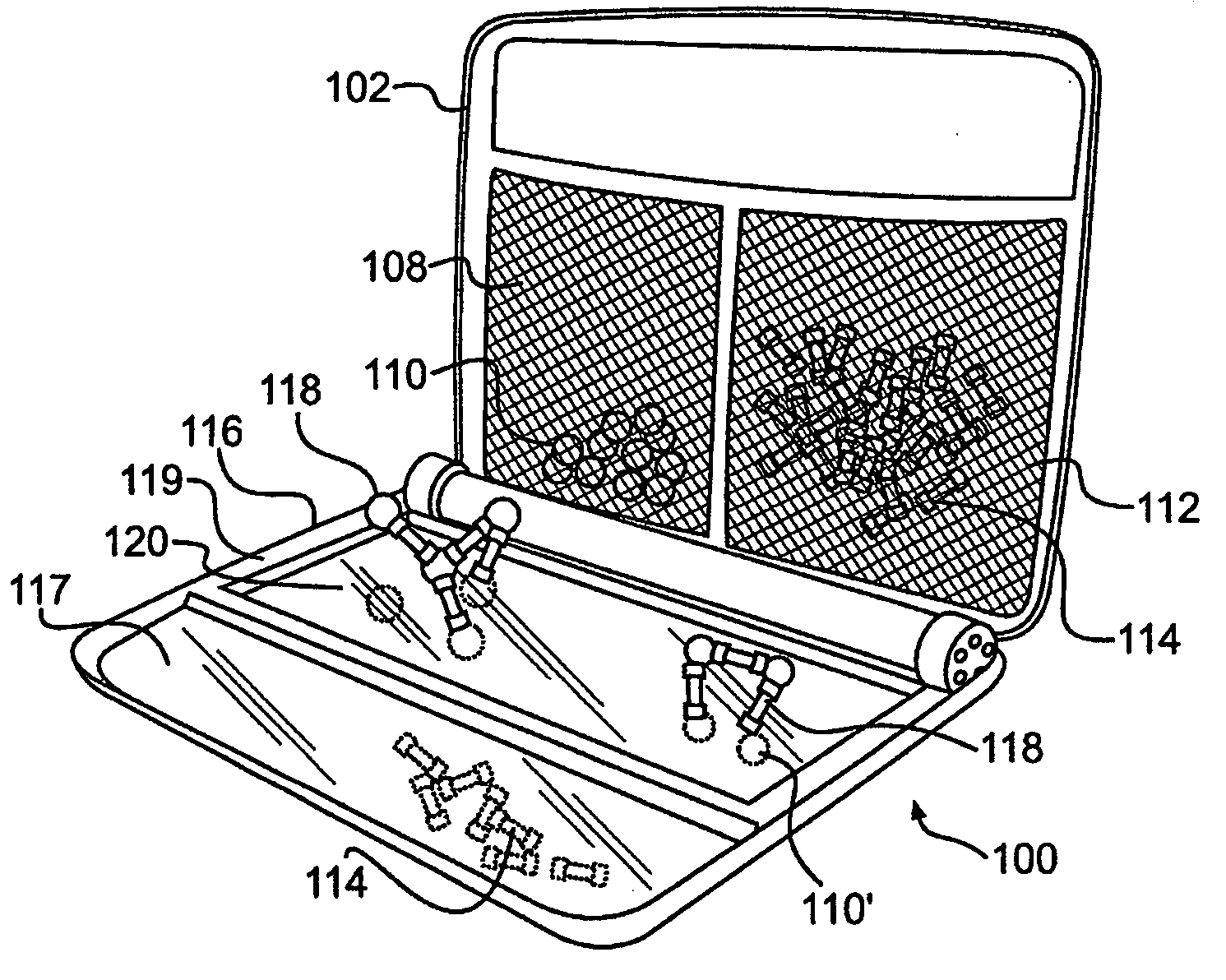

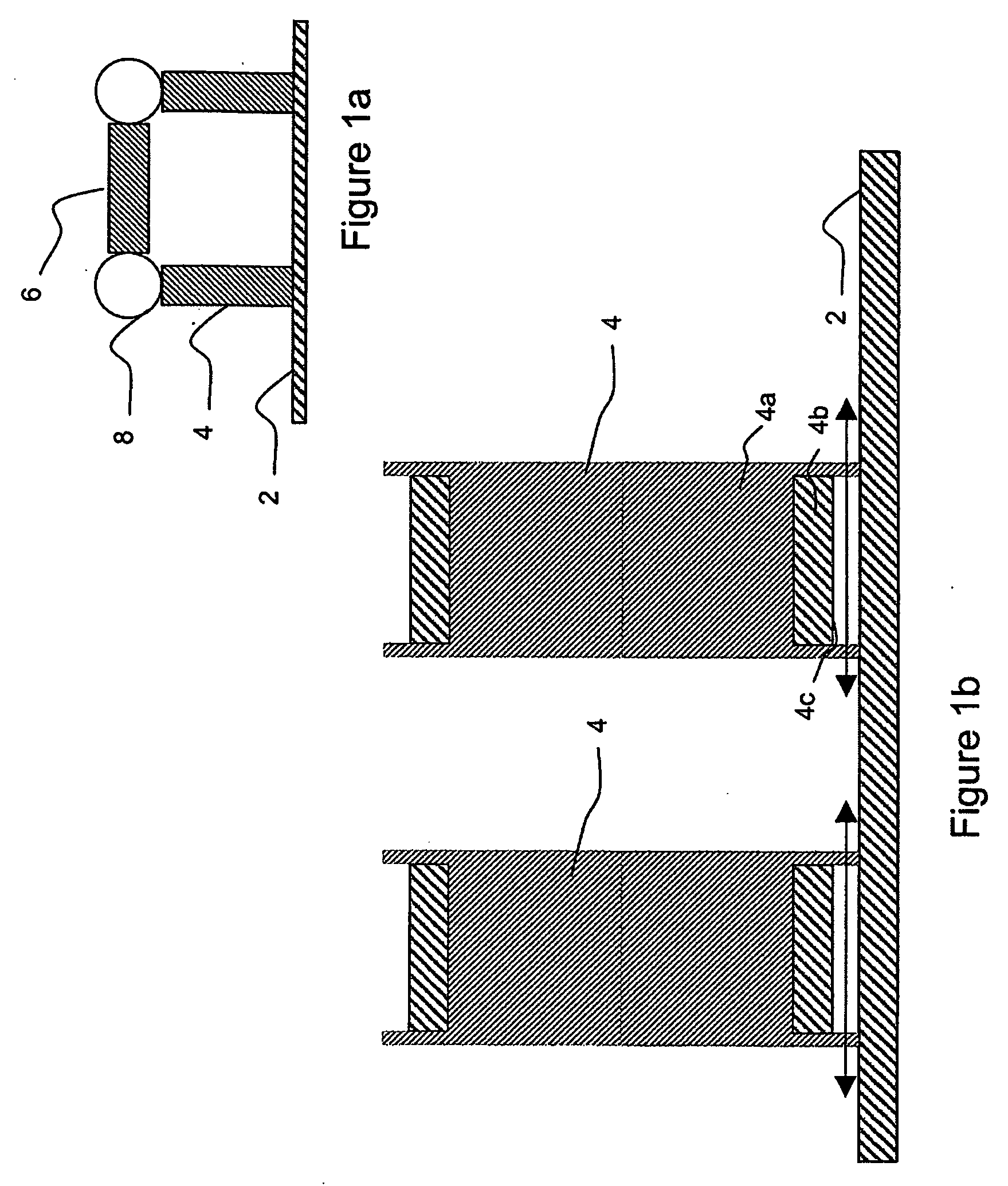

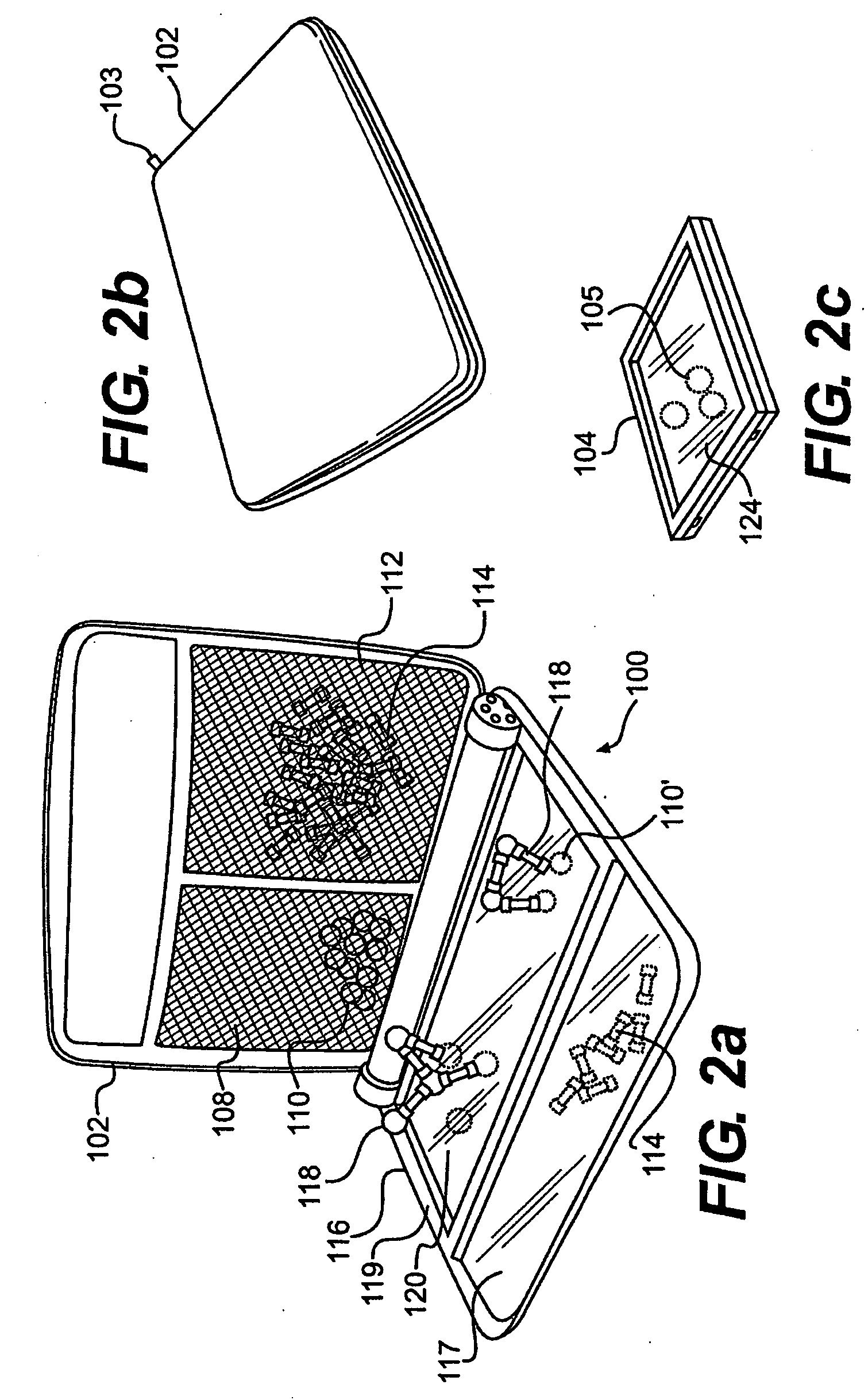

[0021]Aspects of the present invention relate generally to a base plate having a flexible layer holding in place ferromagnetic or magnetic base elements, over which a magnetic assembly can be built. As used herein, the term “flexible” generally refers to the ability of the layer to deform around the base elements to hold them in place in a manner that a rigid surface, such as metal plate, would not. The flexible layer can also be compressible and tacky to further envelope and hold in place the base elements, and also resist lateral movement of the base elements, especially when the flexible layer is compressed between a base element and a magnetic component, as explained in more detail below.

[0022]A flexible layer can be, for example, a membrane made of a thin layer of elastic material. The layer of elastic material could be, for example, a continuous sheet or a fine weave. The overall mechanical properties of the flexible layer can be such that the layer can be reversibly elastical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com