Modular tank unit for ship, barge and rail transportation

a technology for rail transportation and modules, applied in the field of modules or tanks, can solve the problems of lack of terminal facilities or tank farms, lack of active means, economic detriment, etc., and achieve the effect of convenient and simple installation or removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

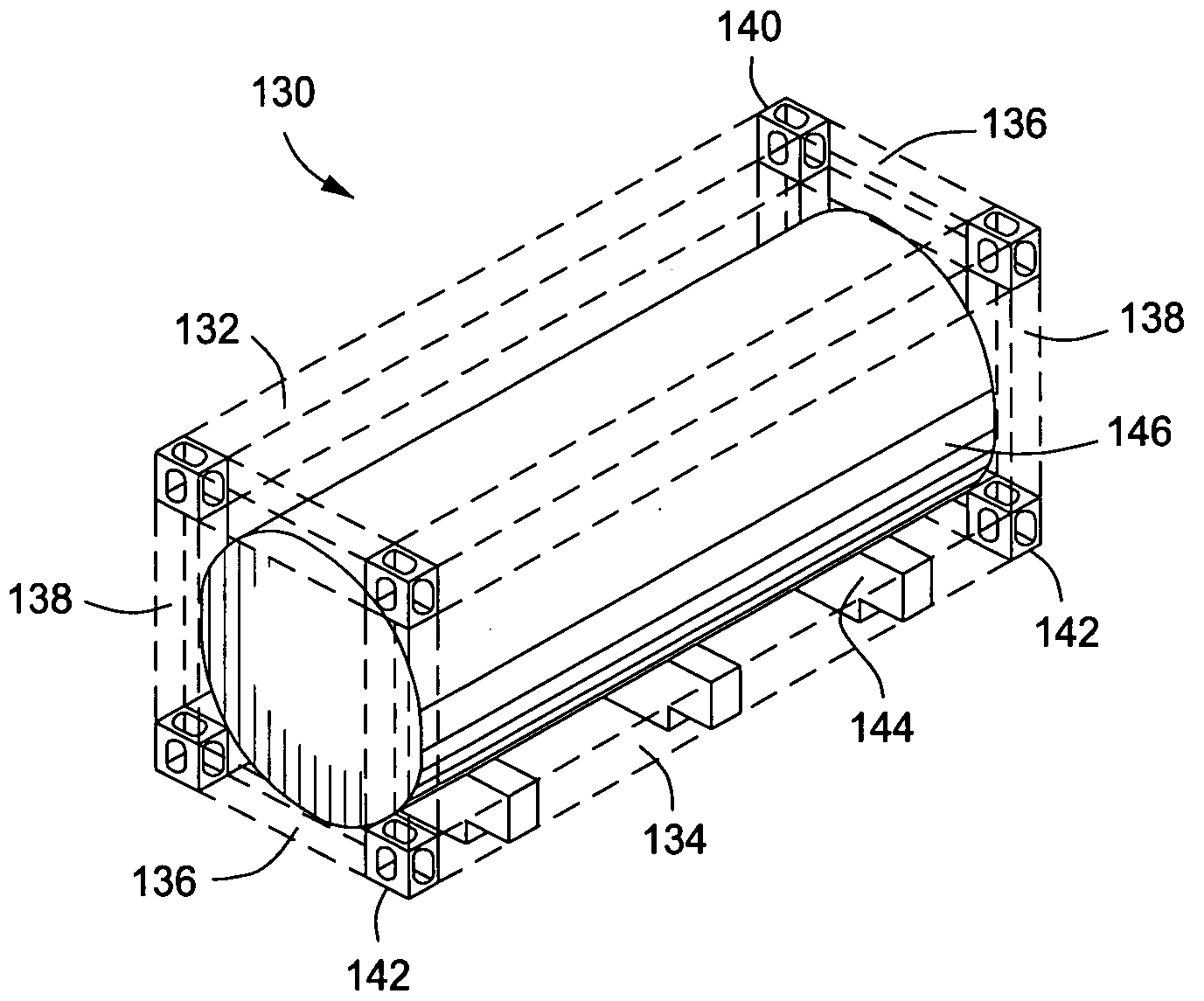

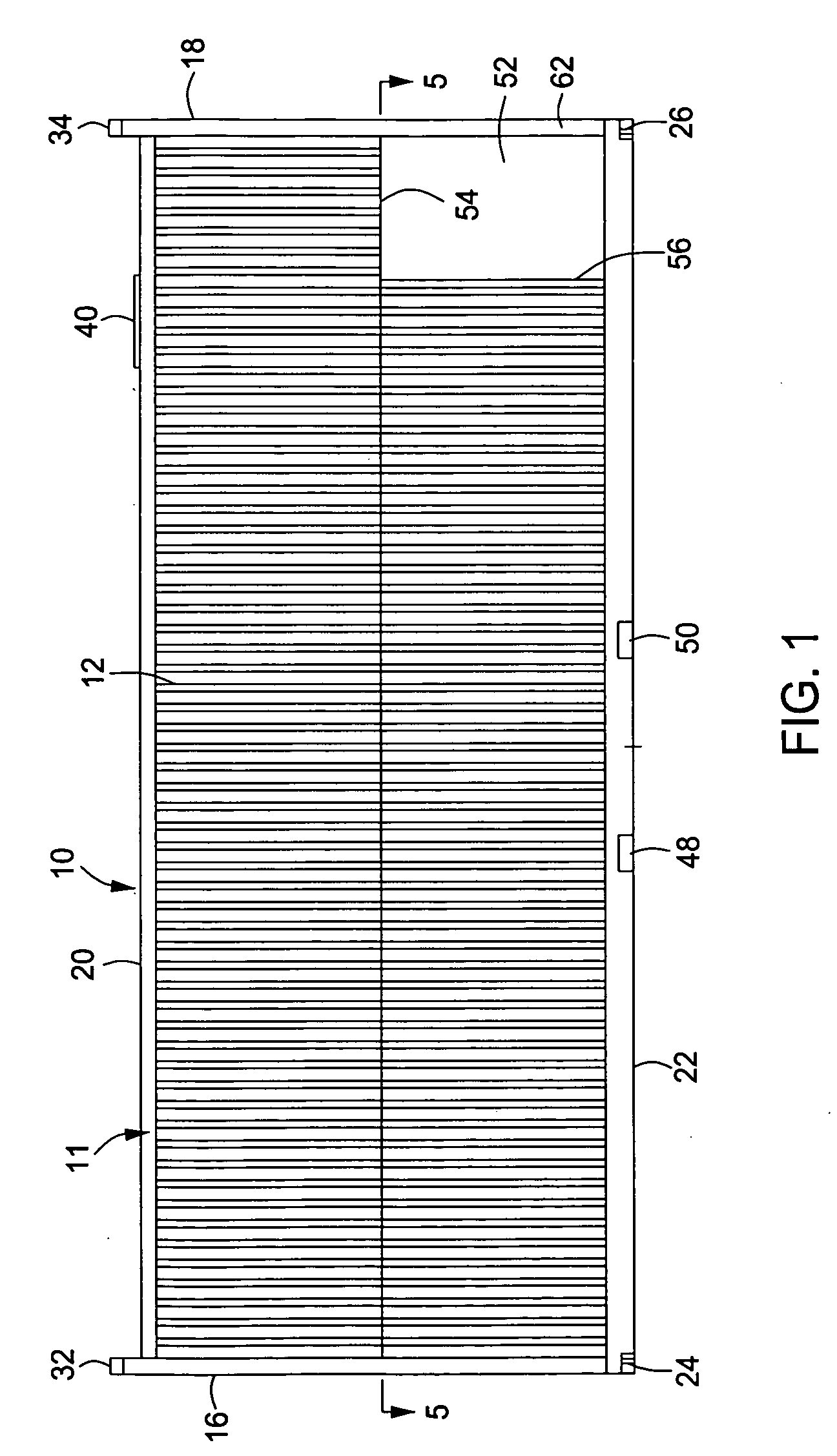

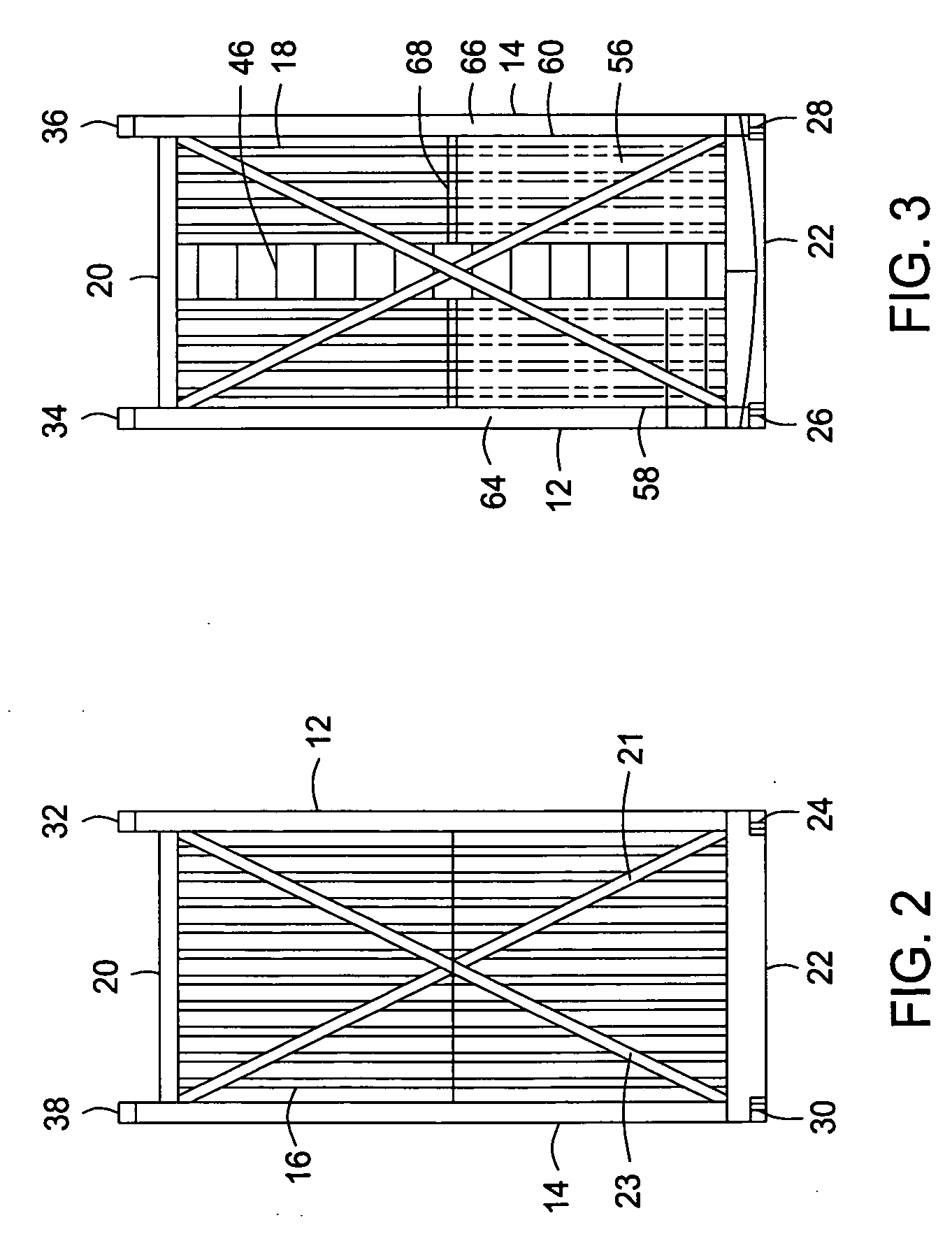

[0075]Referring now to the drawings and first to FIG. 1, a modular tank unit is shown generally at 10 and is preferably of generally rectangular configuration, having a tank framework structure shown generally at 11 and providing a pair of generally parallel side walls 12 and 14 and a pair of generally parallel end walls 16 and 18. The modular tank unit further defines a top wall structure 20 and a bottom wall structure 22. Though shown to be of generally rectangular configuration, it is to be borne in mind that the modular tank unit may have other forms without departing from the spirit and scope of the present invention. Typically, however, the modular tank unit is intended to be received and locked within the container cells of a cargo vessel, hopper barge or train car; thus the footprint that is defined by its bottom structure is typically the same as that of a conventional cargo container. The bottom portion of the framework of the modular tank unit defines corner fittings 24, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com