Measuring apparatus for power loss of magnetic device

a technology of measuring apparatus and magnetic device, which is applied in the direction of measurement device, power measurement by current/voltage, instruments, etc., can solve the problems of high cost of conventional measuring apparatus, increased cost of measuring apparatus, and detrimental to instrument and operator, so as to achieve low cost, loose measurement environment, and power loss of magnetic device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

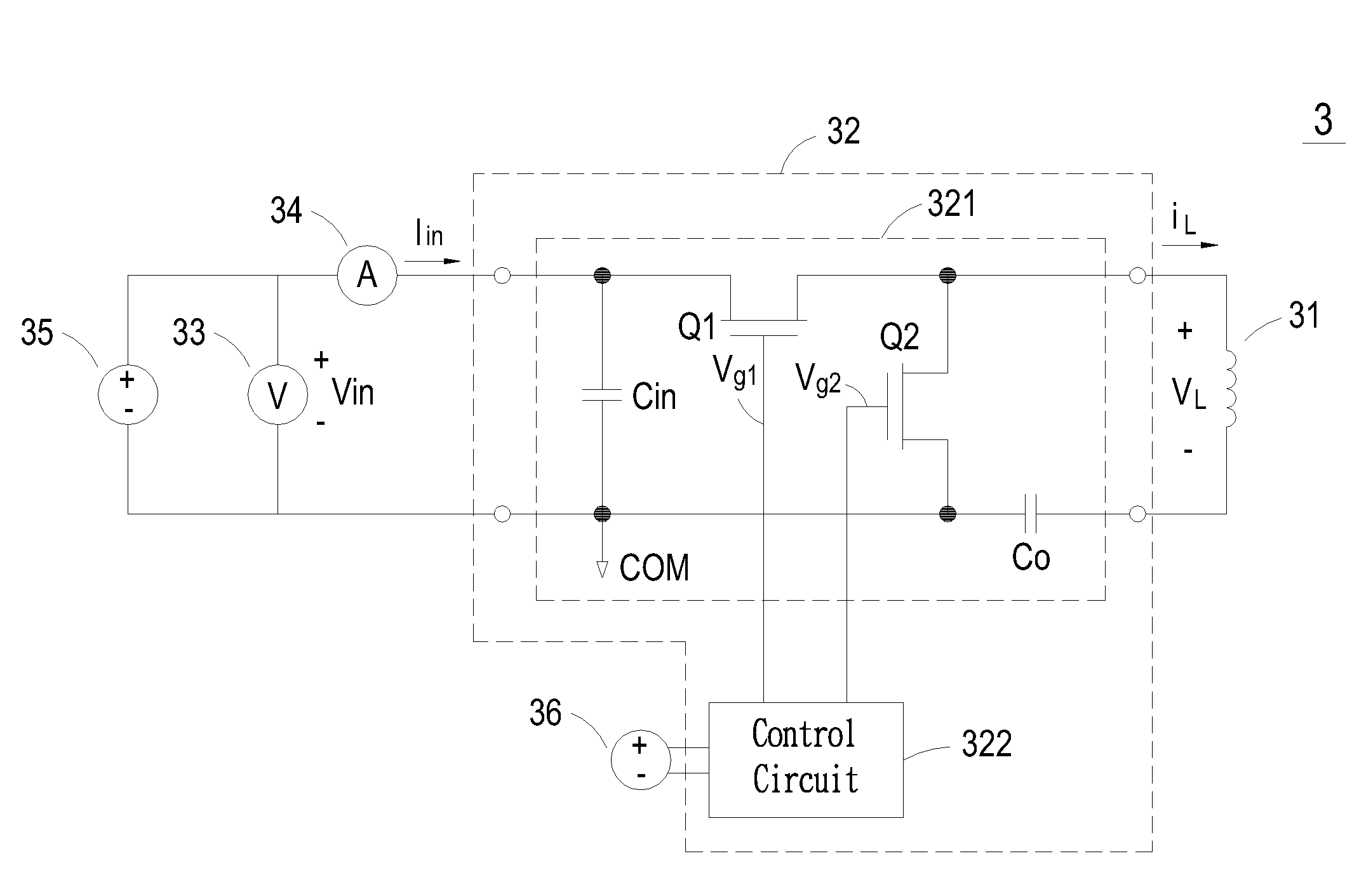

[0032]Referring to FIG. 5, the switch circuit within the measuring apparatus for power loss of magnetic device according to the present invention is shown. As shown in FIG. 5, the switch circuit 321 of the power converter 32 includes an input capacitor Cin, a first switch element Q1, a second switch element Q2, and an output capacitor Co, wherein each element has the same function and structure as the counterpart element disclosed in the previous embodiment. However, the output capacitor Co is connected between the first switch element Q1 and the output side of the power converter 32 in the present embodiment for filtering out the DC component of the output voltage, so that the voltage VL across the magnetic device 31 is a rectangular wave without any DC component. The current iL of the magnetic device 31 is a triangular wave as well, and the magnetic core of the magnetic device 31 will generate a corresponding triangular flux and cause power loss. Therefore, the power loss P of the...

third embodiment

[0033]Referring to FIG. 6, the switch circuit within the measuring apparatus for power loss of magnetic device according to the present invention is shown. As shown in FIG. 6, the switch circuit 321 of the power converter 32 includes an input capacitor Cin, a third switch element Q3, a fourth switch element Q4, a fifth switch element Q5, a sixth switch element Q6, and an output capacitor Co, wherein the input capacitor Cin is connected in parallel with the DC input side of the power converter 32 and a common node COM for filtering. The third switch element Q3 and the sixth switch element Q6 are connected in series with node A, and the other end of the third switch element Q3 and the other end of the sixth switch element Q6 are respectively connected to the first DC power supply 35. The fifth switch element Q5 and the fourth switch element Q4 are connected in series with node B, and the other end of the fifth switch element Q5 and the other end of the fourth switch element Q4 are res...

fifth embodiment

[0034]Referring to FIG. 8, the switch circuit within the measuring apparatus for power loss of magnetic device according to the present invention is shown. As shown in FIG. 8, the switch circuit 321 of the power converter 32 includes an input capacitor Cin, a third switch element Q3, a fourth switch element Q4, a fifth switch element Q5, a sixth switch element Q6, and a first capacitor C, wherein the input capacitor Cin is connected in parallel with the DC input side of the power converter 32 for filtering. The third switch element Q3 and the sixth switch element Q6 are connected in series with node A, and the other end of the third switch element Q3 and the other end of the sixth switch element Q6 are respectively connected to the first DC power supply 35 and the common node COM. The fifth switch element Q5 and the fourth switch element Q4 are connected in series with node B and then connected to the first capacitor C, and the other end of the fourth switch element Q4 and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com