Golf Club Head and Method of Varying Moment of Inertia of Same

a golf club head and moment of inertia technology, applied in the field of golf club heads, can solve the problem of not revealing a method applicable to a broad range of golf club heads for optimizing mass characteristics, and achieve the effect of increasing the moment of inertia of the sol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

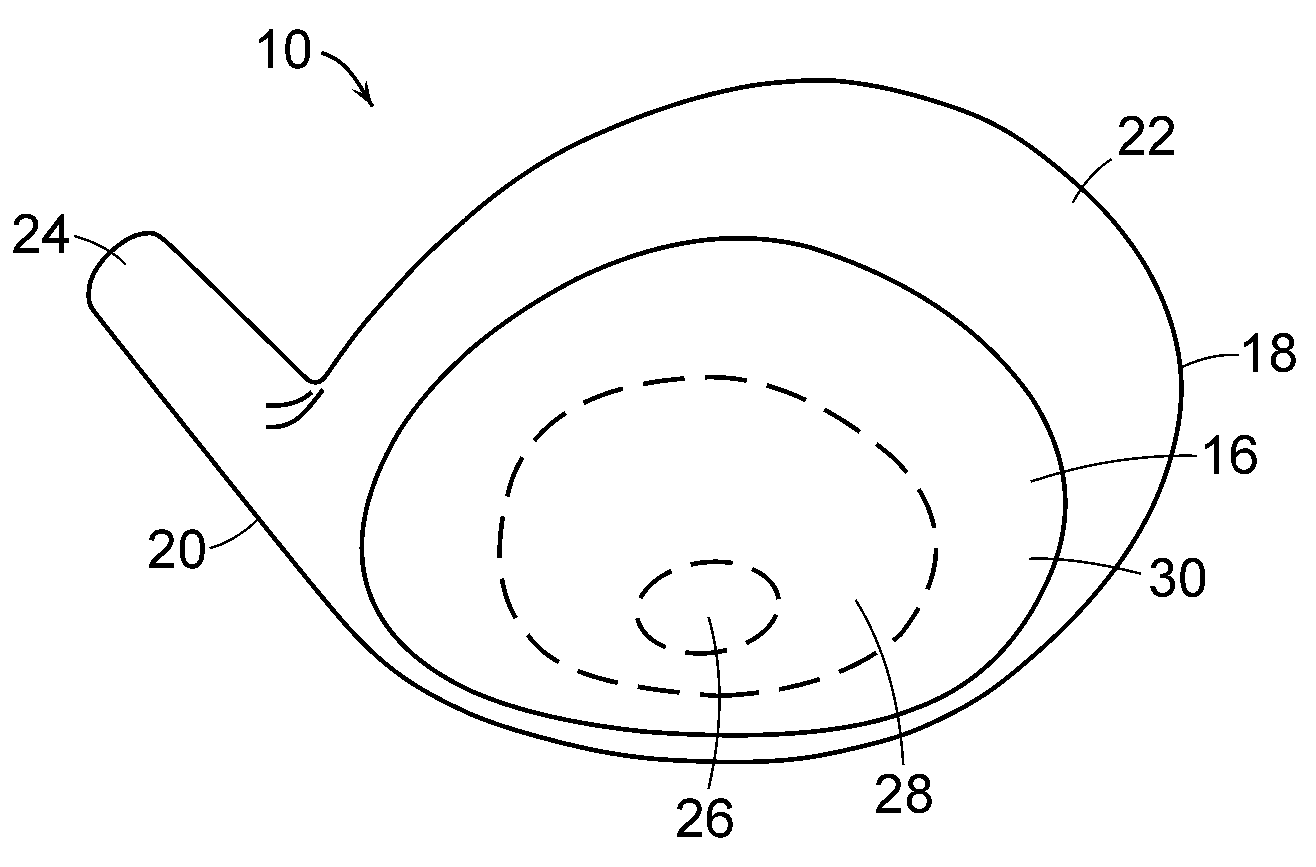

[0041]In the present invention, the centroid radius of a driver club head is determined. In one example, a driver club head having a volume of 460 cm3 is used. Such a club head 10, shown in FIGS. 1-3, has a hitting face 12, crown 14, sole 16, toe 18 and heel 20. Club head 10 also has skirt 22, which connects crown 14 to sole 16, and hosel 24 adapted to receive a shaft (not shown).

[0042]Hitting face 12 should have a certain thickness to withstand repeated impacts with golf balls or a given thickness profile to maximize the energy transfer to the balls; accordingly, a limited amount of mass may be redistributed from the hitting face to improve MOI. Crown 14 and skirt 22 are generally already made sufficiently thin so that more mass can be relocated to the location(s) below the center of gravity. Hence, it is preferred in this embodiment that mass is not redistributed therefrom to improve MOI. In this embodiment, mass from sole 16 is redistributed therewithin to improve the MOI and a c...

fourth embodiment

[0059]In the present invention, a method of tracking shifts in MOI and center of gravity in the vertical direction due to mass distribution in a sole of a golf club head is used to optimize both MOI and the position of center of gravity of a club head. Starting in the center of the sole and radiating toward the heel, toe, back and face, a typical sole curves up and away from the ground plane. Concentrating mass in the perimeter areas of the sole, or outside of the centroid radius as defined in previous embodiments, will generally result in an increase of MOI as compared to a baseline MOI; however, that concentration of mass may also cause the center of gravity of the club head to move up, toward the crown, as more mass is located in areas of the sole that are farther away from the ground plane.

[0060]To increase MOI but keep the center of gravity of the club head acceptably low, a first two-dimensional matrix is created to model the sole. The sole is divided into equally-sized elemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com