Compost Ventilation

a technology of compost heap and ventilation pipe, which is applied in the field of ventilation pipe, can solve the problems of affecting the ventilation of compost heap, and prone to damage, and achieves the effect of facilitating the connection of ventilation pip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

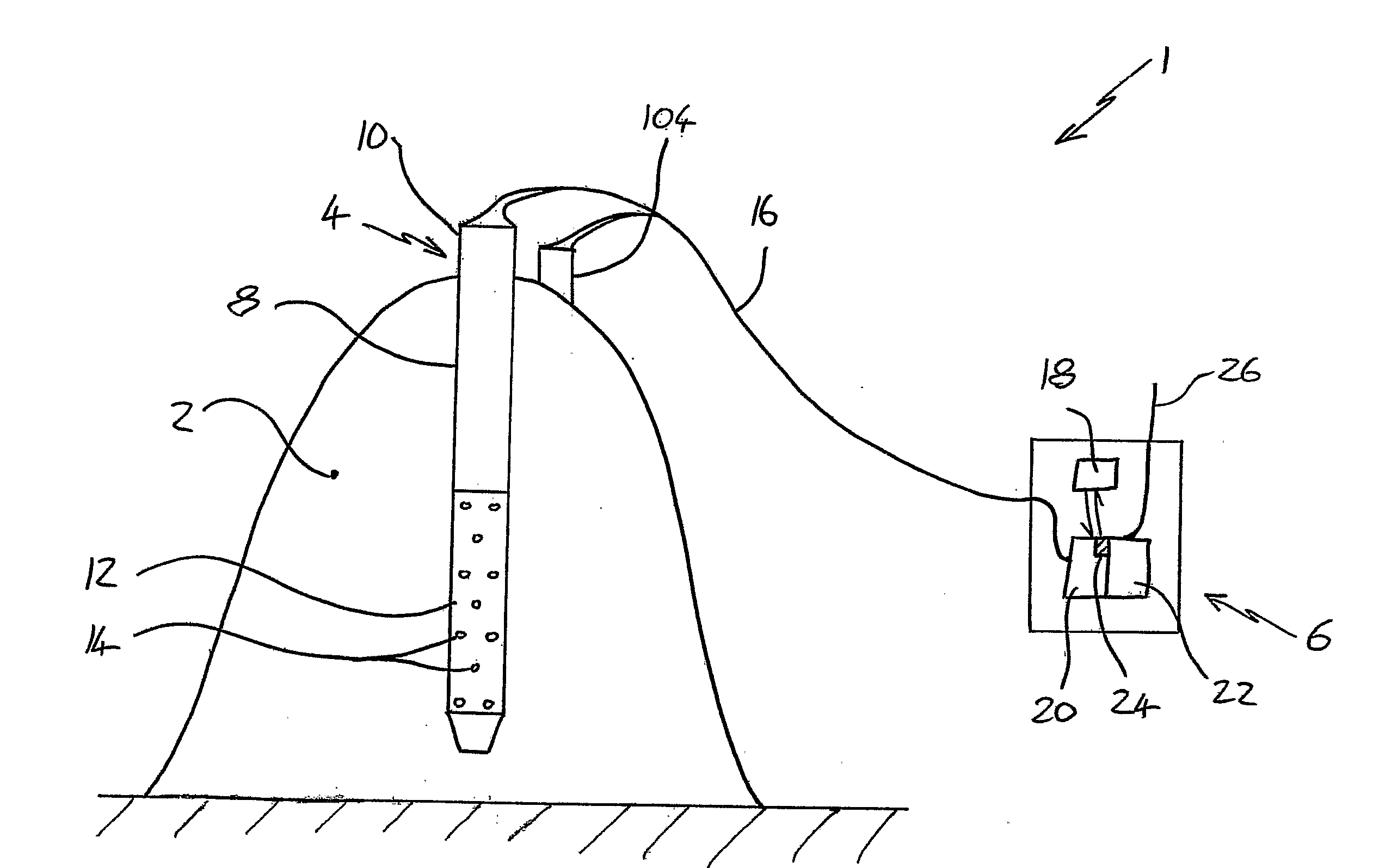

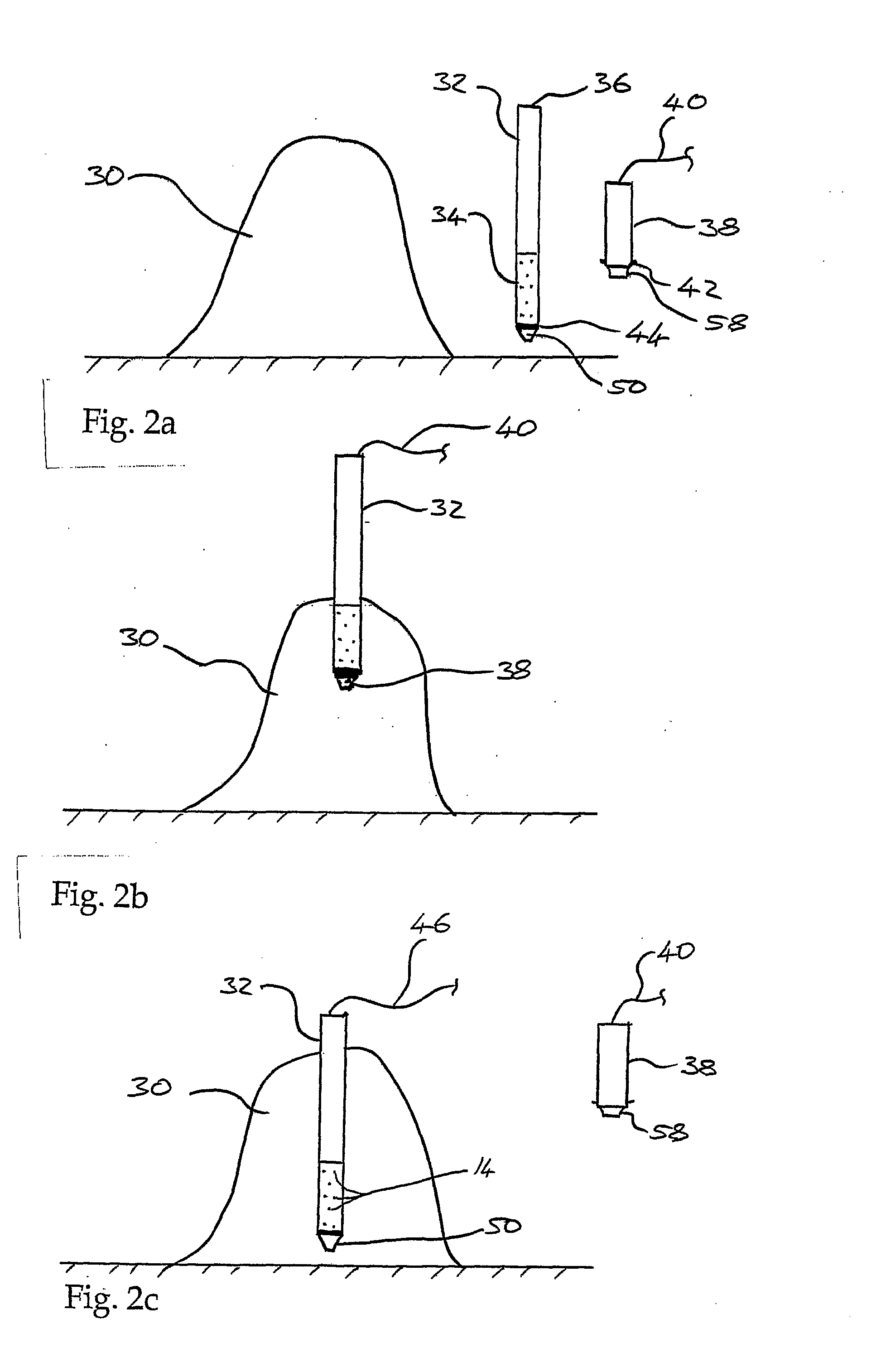

[0024]FIG. 1 shows a composting apparatus 1 comprising a compost heap 2 comprising compostable material. There is at least one ventilation pipe 4 and air moving means 6, in this case a fan. The ventilation pipe 4 comprised a pipe wall 8 defining a conduit 10 for gas. The ventilation pipe 4 has a connection end 10 and a ventilation portion 12. The ventilation portion 12 has a plurality of aeration holes 14 extending through the pipe wall 8. The ventilation portion 12 is located within the compost heap 2 and the connection end 10 is coupled to the air moving means 6 by a pipe 16 such that, when active, the air moving means 6 causes movement of air through the aeration holes 14 towards the air moving means 6. In this case the ventilation pipe is a 76 mm outer diameter steel pipe having a wall thickness of 3 mm.

[0025]The air moving means 6 comprise a controller 18, an air mover 20, a filter 22 and a sensor 24. The controller 18 receives a signal from the sensor 24 and controls the air m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com