Dual ammunition magazine pouch

a dual-use, magazine-type technology, applied in the direction of ammunition loading, de-stacking articles, transportation and packaging, etc., can solve the problems of lack of fine motor skills, difficulty in drawing a single magazine from the pouch, and pulling the other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

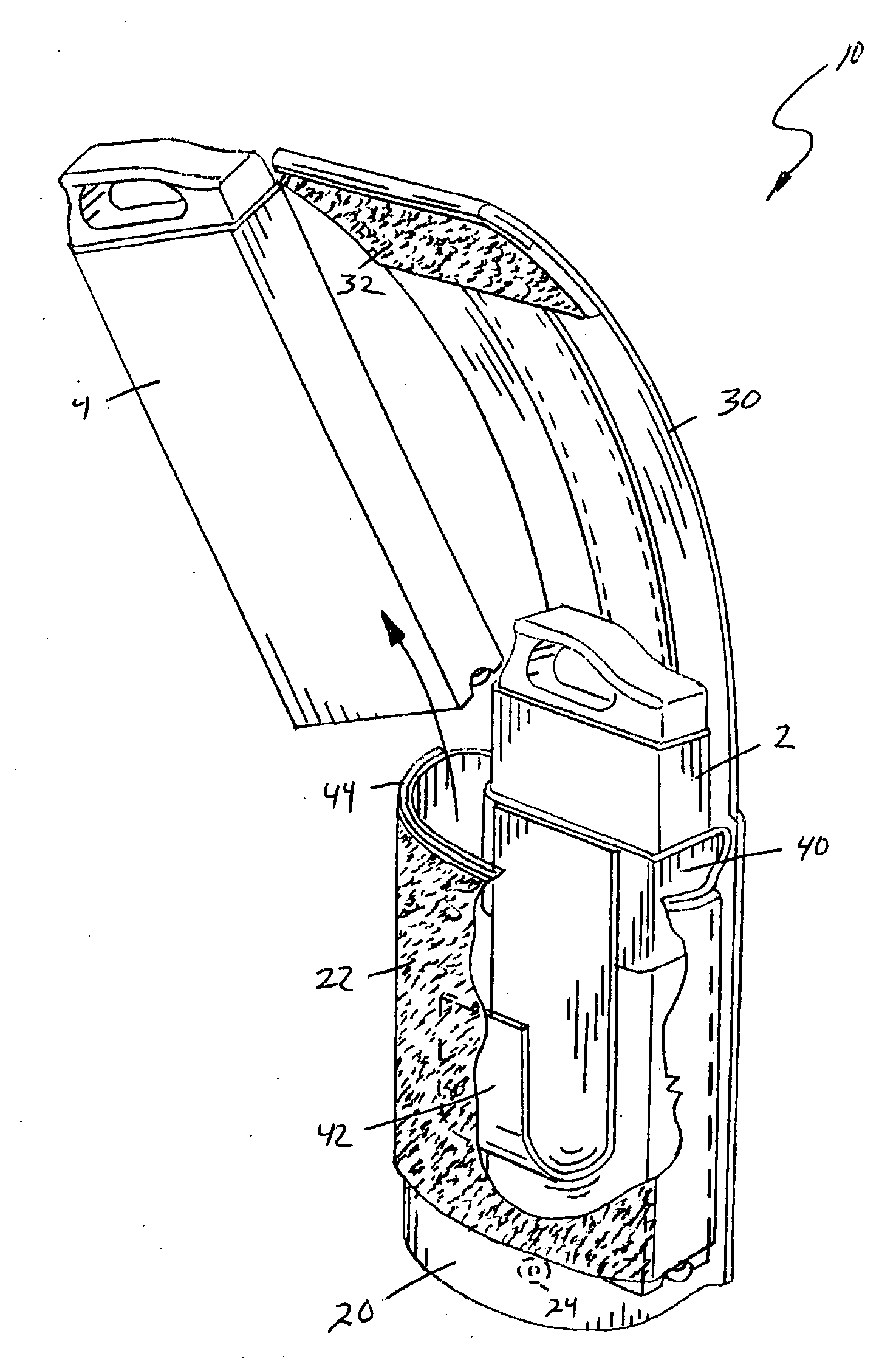

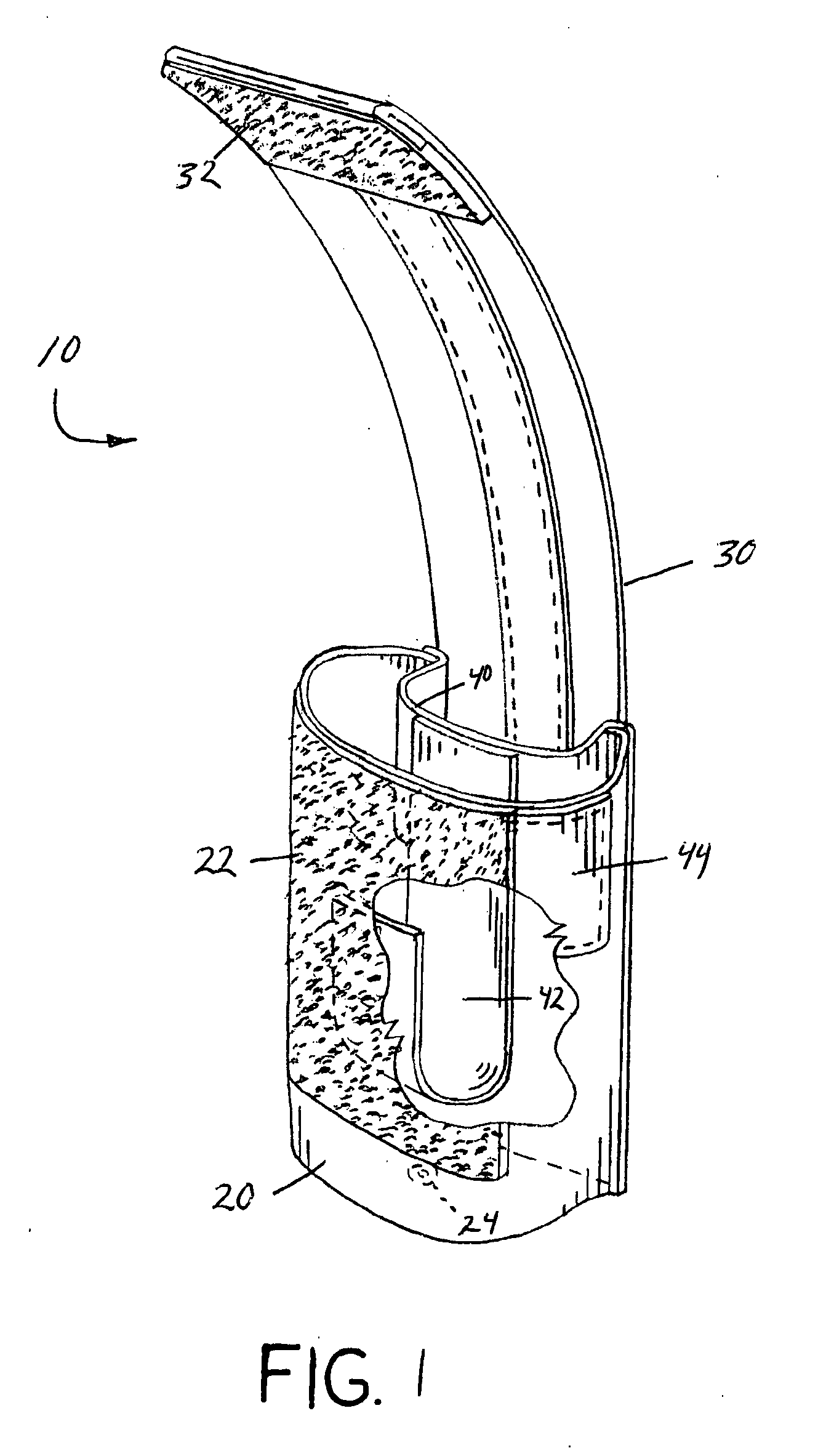

[0024]FIGS. 1-8 illustrate the dual magazine pouch of this invention, which is designated generally as reference numeral 10. Pouch 10 has a main body formed by a cargo pocket 20 sewn to an elongated back / flap 30 to define the pouch interior 11. As shown, the fabric of cargo pocket 20 is folded and hemmed to have a front wall, two end walls and a bottom. Back / flap 30 extends above cargo pocket 20 and folds over to enclose the open mouth 13 of pouch 10. As shown, hook and loop (Velcro®) fastening patches 22 and 32 are sewn to the front of cargo pocket 20 and the end of back / flap 30 to close and secure pouch 10. Although hook and loop patches are used to secure the pouch in a closed position, buckles, snaps, buttons, frogs or any other suitable type of fastening method can be used to secure the pouch. PALS webbing 34 is sewn to the back of the back / flap 30. It should also be noted that the bottom of cargo pocket 20 has an opening 23 and a brass grommet 24 to allow sand, dirt and debris...

second embodiment

[0027]FIGS. 9-11 illustrate the dual magazine pouch of this invention, which is designated generally as reference numeral 50. Pouch 50 is identical in construction to pouch 10, but differs slightly regarding the elevator mechanism. As shown, the elastic elevator band 42 of pouch 10 is replaced with a length of elastic cord 52. Ideally, elastic cord 52 is constructed of continuous rubber strands with an outer nylon sheath. This type of elastic cord is well known and commonly referred to as bungee or shock cord. Elastic cord 52 is selected to be relative thin and pliable, yet provide enough stretch and tension to lift the ammunition magazine from the pouch when opened. Two lengths of nylon webbing 54 and 56 are folded over and sewn to cargo pocket 20′ and retention band 40′, respectively to form at web loop through which elastic cord 52 runs. The ends of elastic cord 52 are knotted together and the looped elastic cord 52 hangs down within pouch interior 11 to form the saddle, in which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com