Device and procedure for axial thrust compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

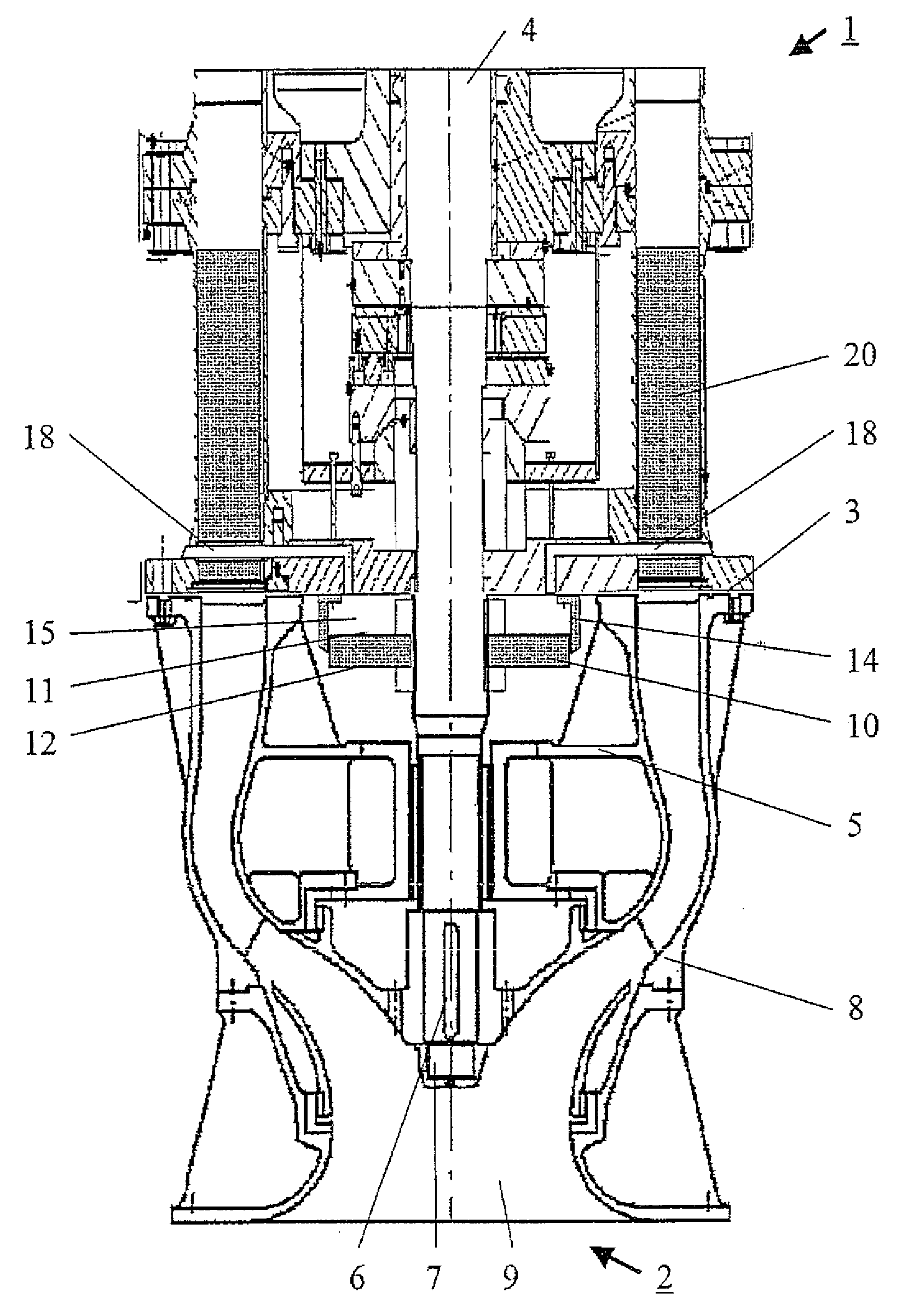

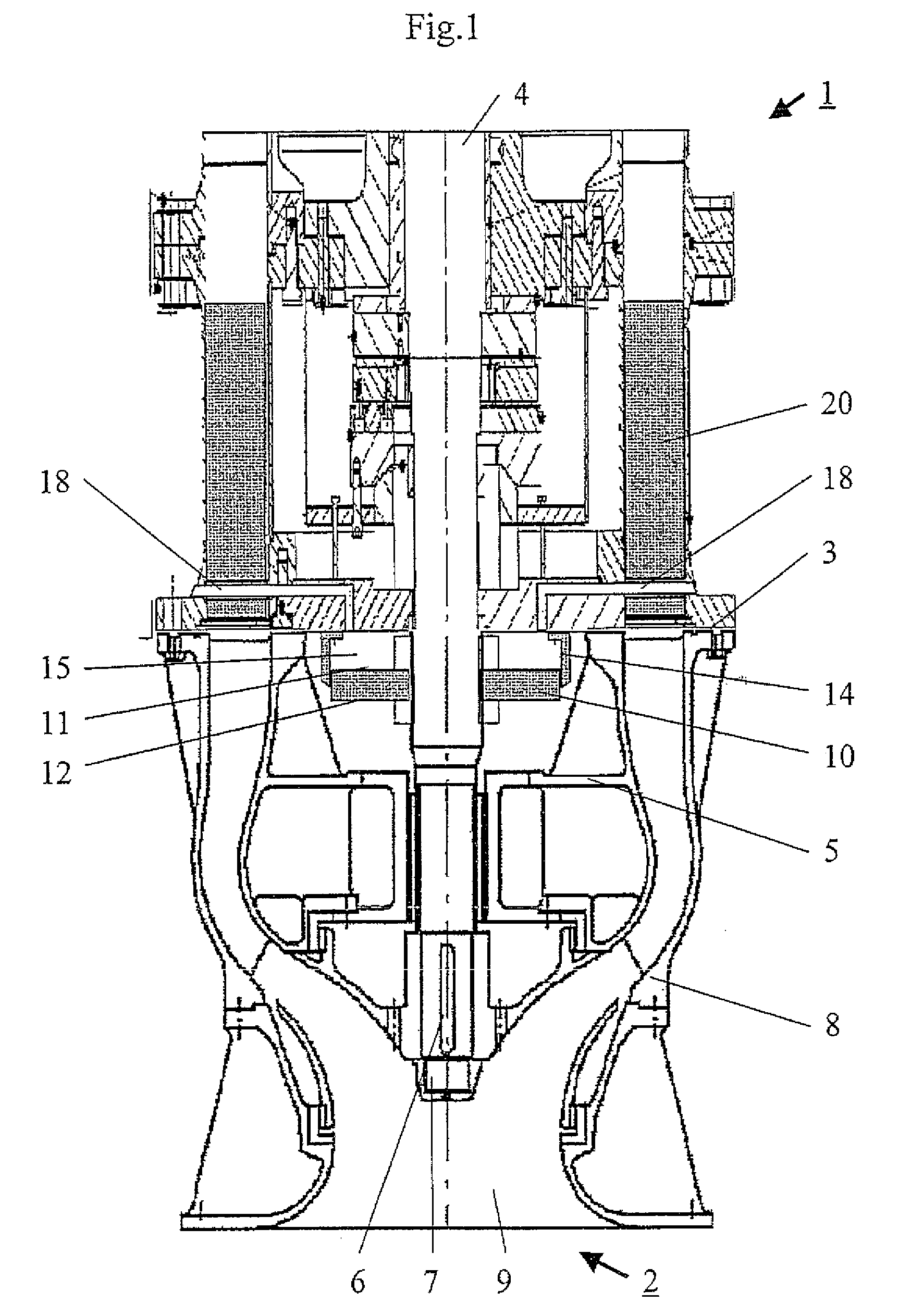

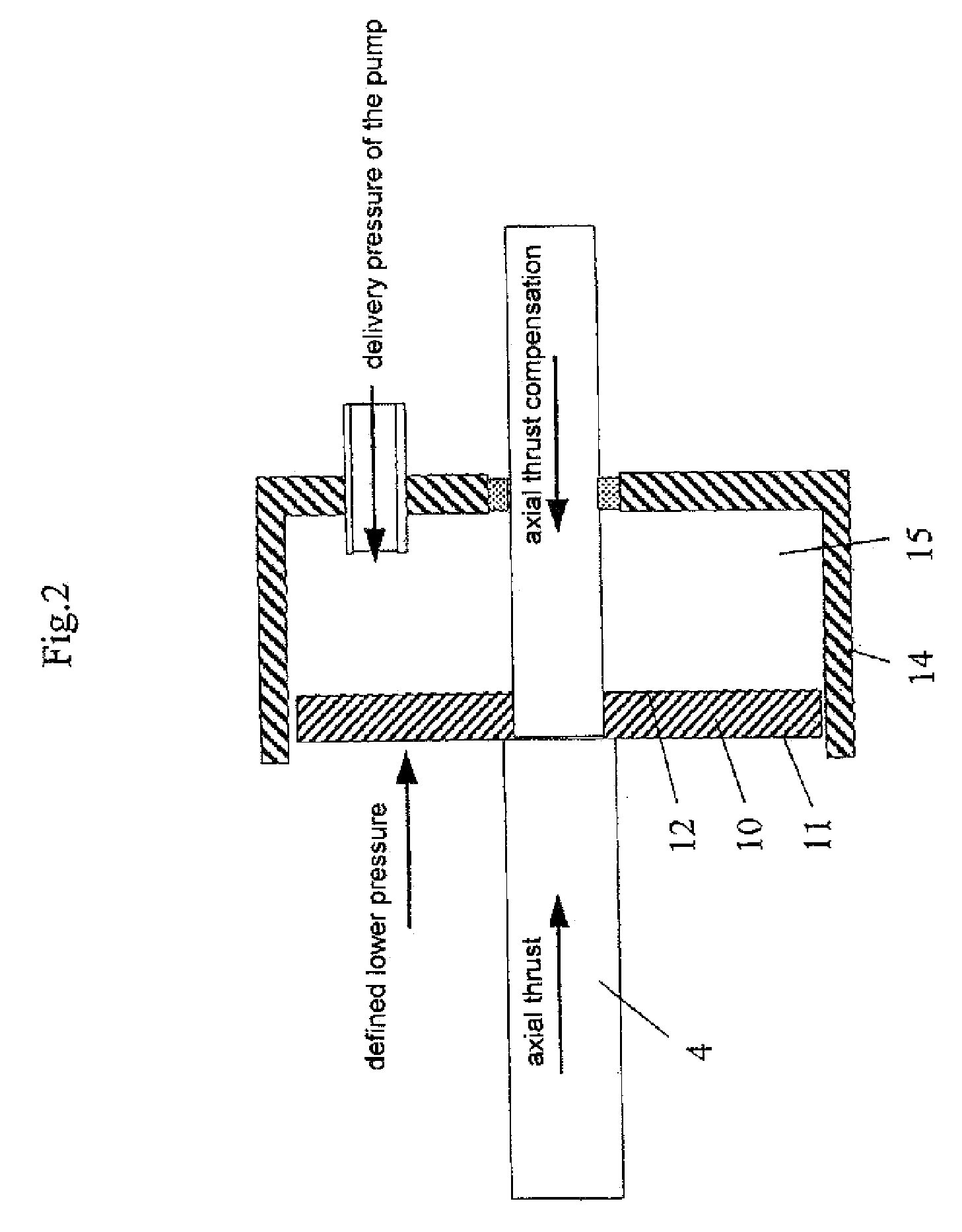

[0041]FIG. 1 shows an embodiment by way of example of a vertical pump. In this connection, in the simplest case the term vertical pump is used to denote the combination of a drive unit with a rotary pump unit, which are arranged one above the other substantially perpendicularly to the level on which the pump stands. As noted in the opening part of this specification, the term vertical pump is used here to denote a pump in which in use the pump shaft is oriented substantially vertically. Furthermore it should be established for clarification purposes that, for a vertical pump, when pumping a fluid against the force of gravity ‘down’ is defined in relation to the vertical pump by the suction side of the pump unit and correspondingly ‘up’ in relation to the vertical pump corresponds to the pressure side of the pump unit.

[0042]The vertical pump shown in FIG. 1 comprises a drive unit 1 which can be for example an electric motor and a rotary pump unit 2 which is fixed to the drive unit 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com