Furniture glide

a furniture glide and glide technology, applied in the field of furniture, can solve the problems of generating unpleasant noise and vibration sensations through the chair, causing scratches, abrasion or dark rubber markings, and high floor cleaning costs, so as to reduce the risk of accidental separation of the furniture glide and prevent or reduce the generation of unpleasant noise and vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

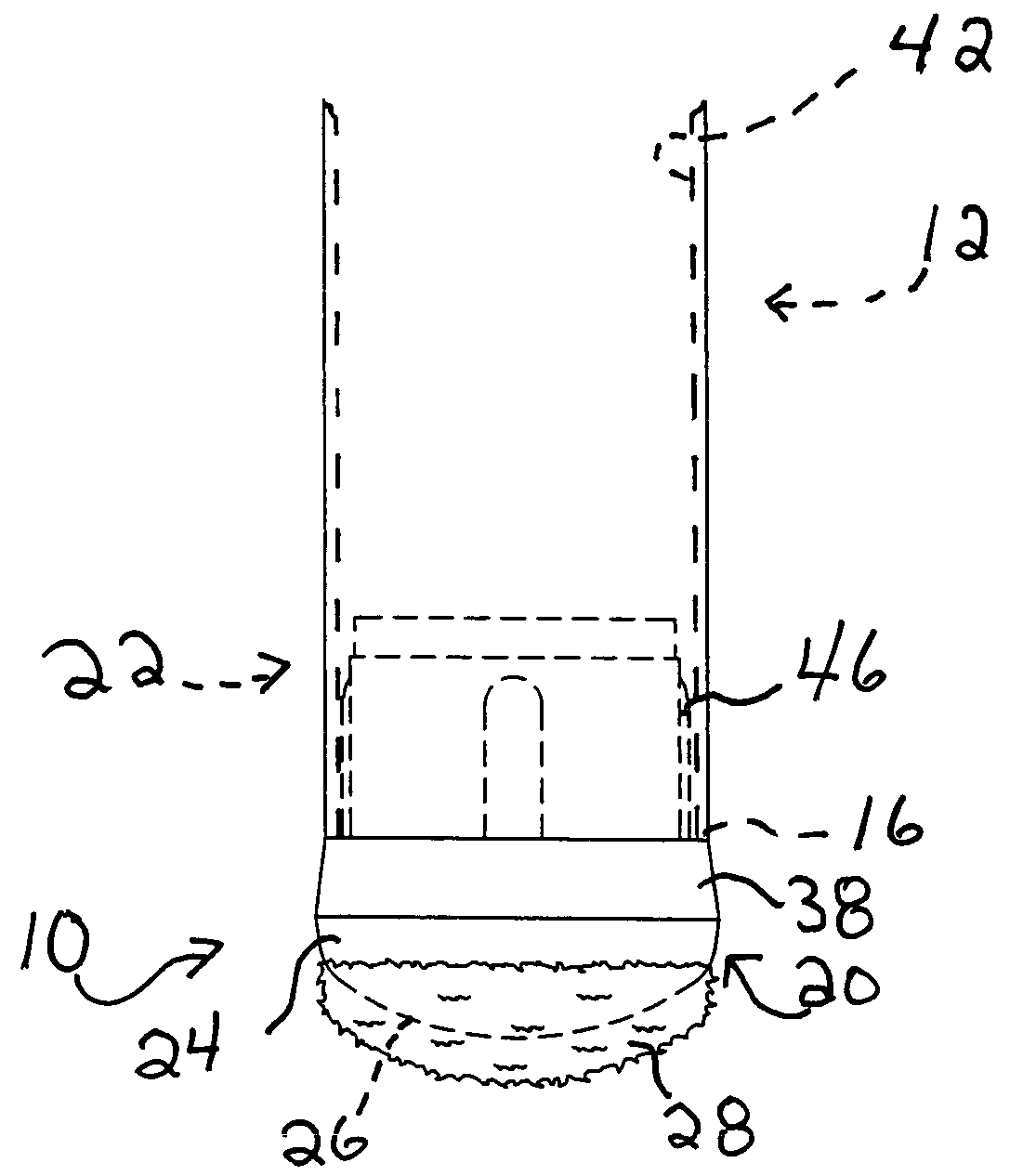

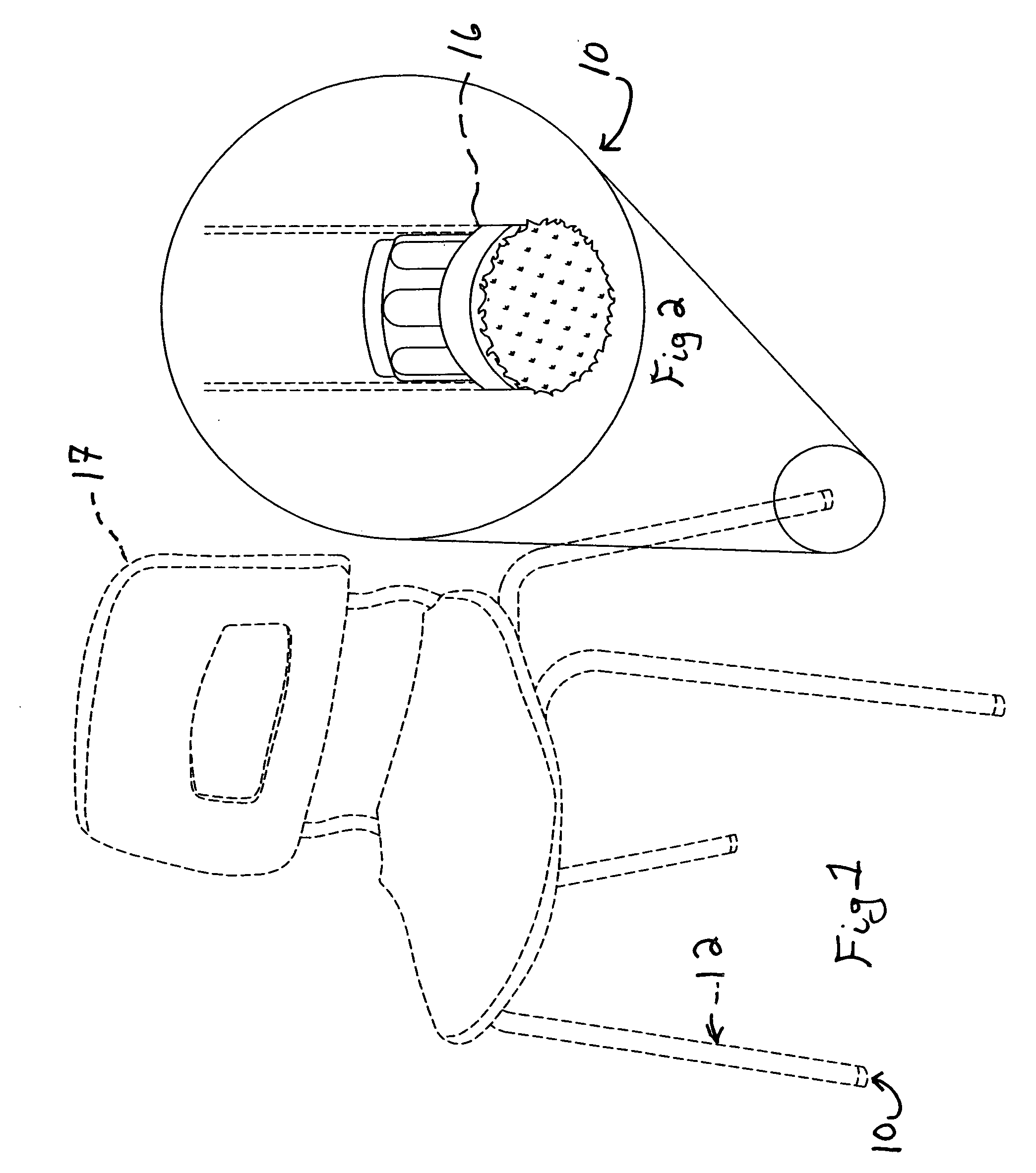

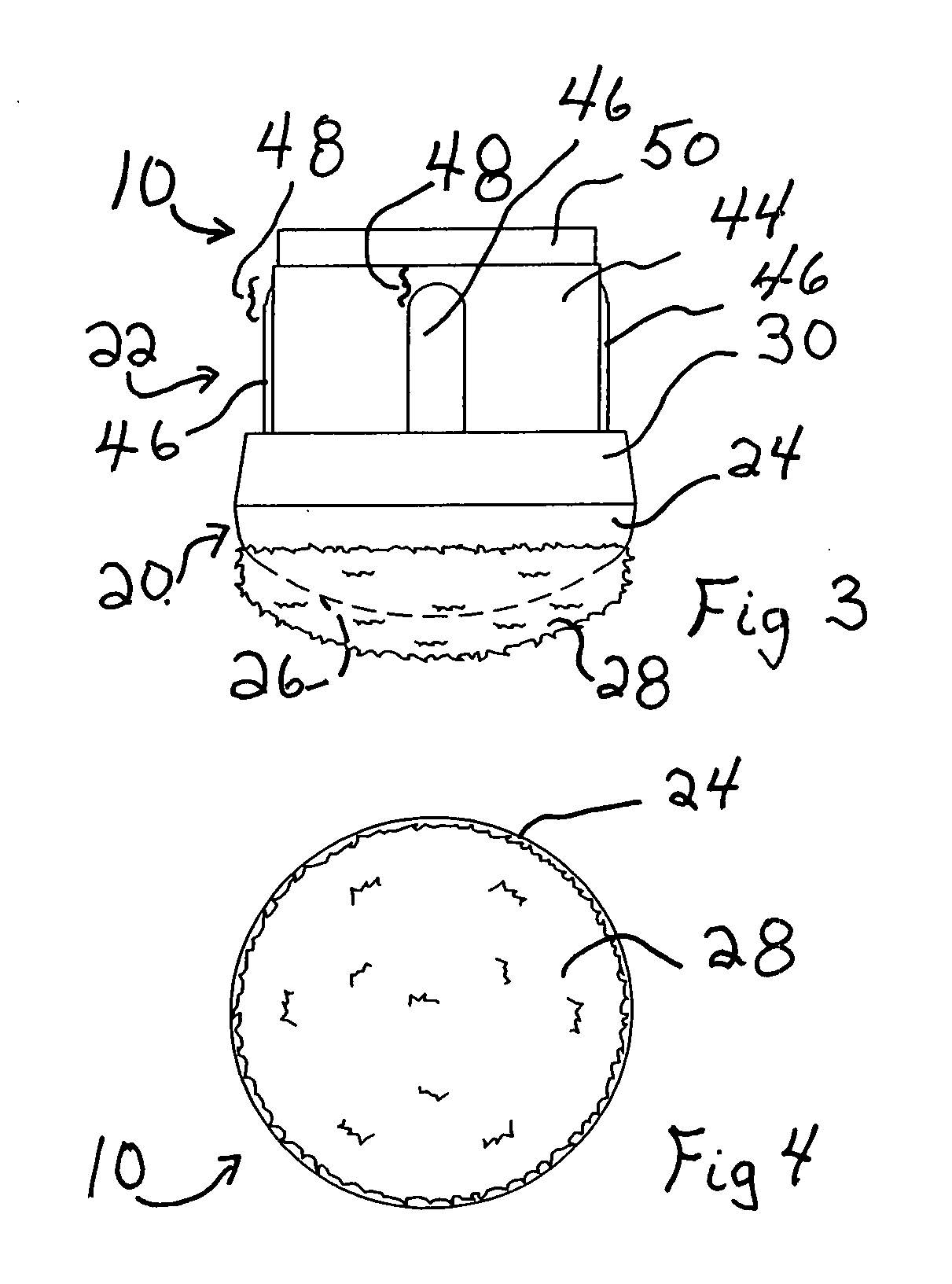

[0024]FIGS. 1 to 6 illustrate a furniture glide 10 in accordance with an embodiment of the present invention. As seen in FIGS. 1, 2, 5 and 6, the furniture glide 10 is usable for supporting a furniture leg 12 on a leg supporting surface 14 (shown in FIG. 6). Referring to FIGS. 2, 5 and 6, the furniture leg 12 defines a leg free end 16.

[0025]As shown in FIG. 1, in some embodiments of the invention, the furniture leg 12 is a leg of a chair 17. However, in other embodiments of the invention, the furniture leg 12 is a furniture leg 12 of any other suitable piece of furniture.

[0026]As seen in FIG. 1, in some embodiments of the invention, the furniture leg 12 extends in a non-perpendicular direction relatively to the leg supporting surface 14 (not seen in FIG. 1). However, in alternative embodiments of the invention, as seen in FIG. 6, the furniture leg 12 extends substantially perpendicularly to the leg supporting surface 14.

[0027]Referring to FIG. 3, the furniture glide 10 includes a sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com