Injection molding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

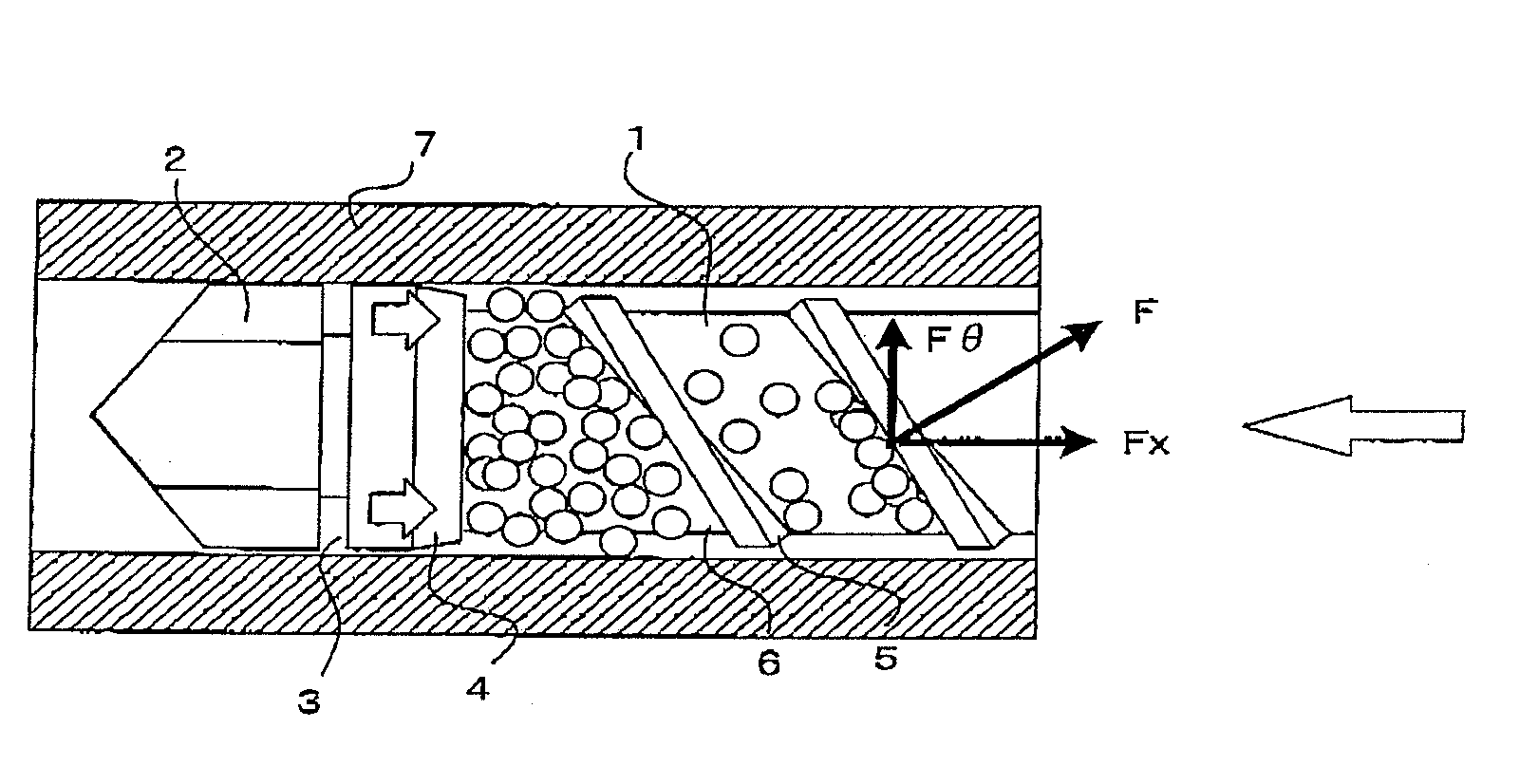

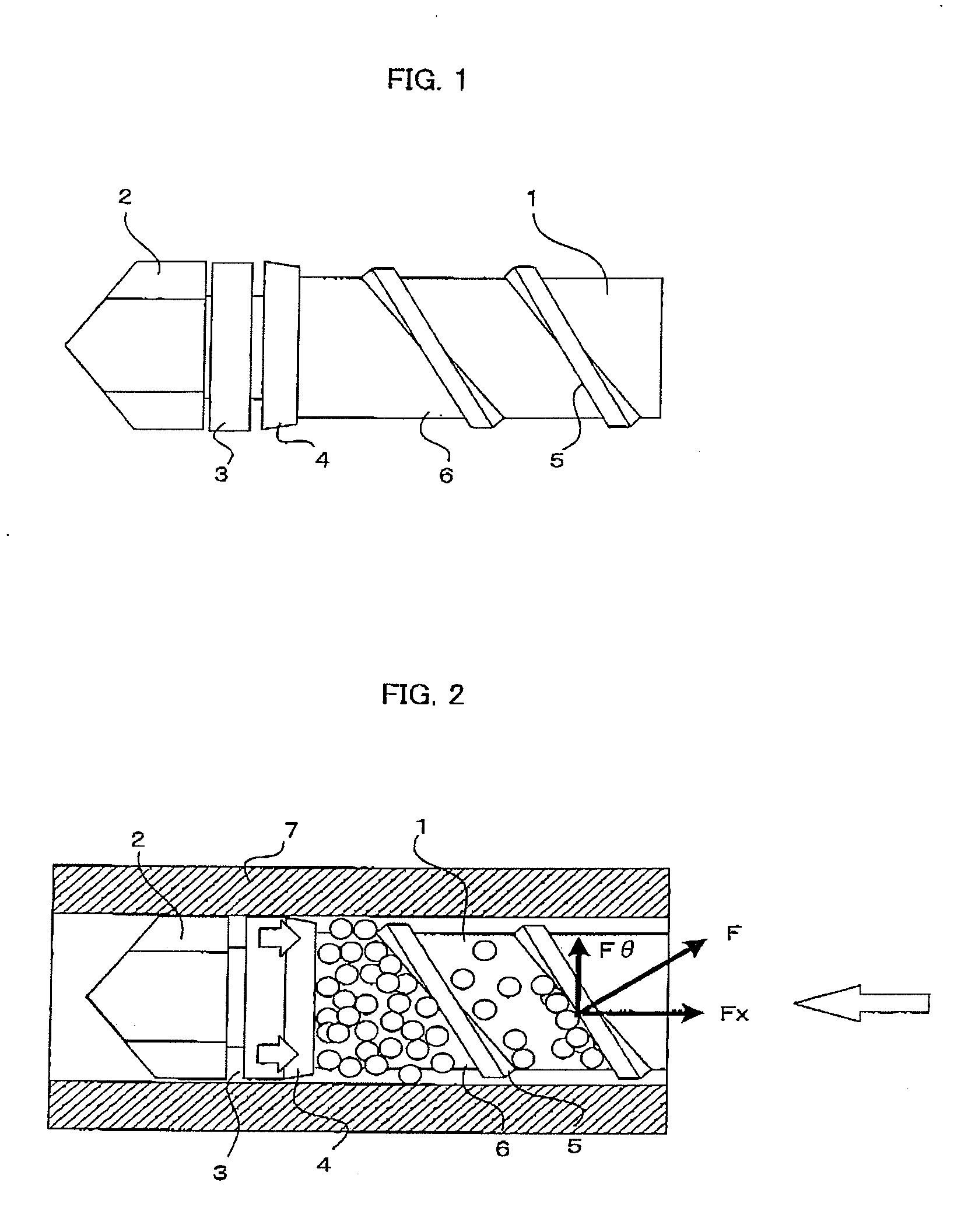

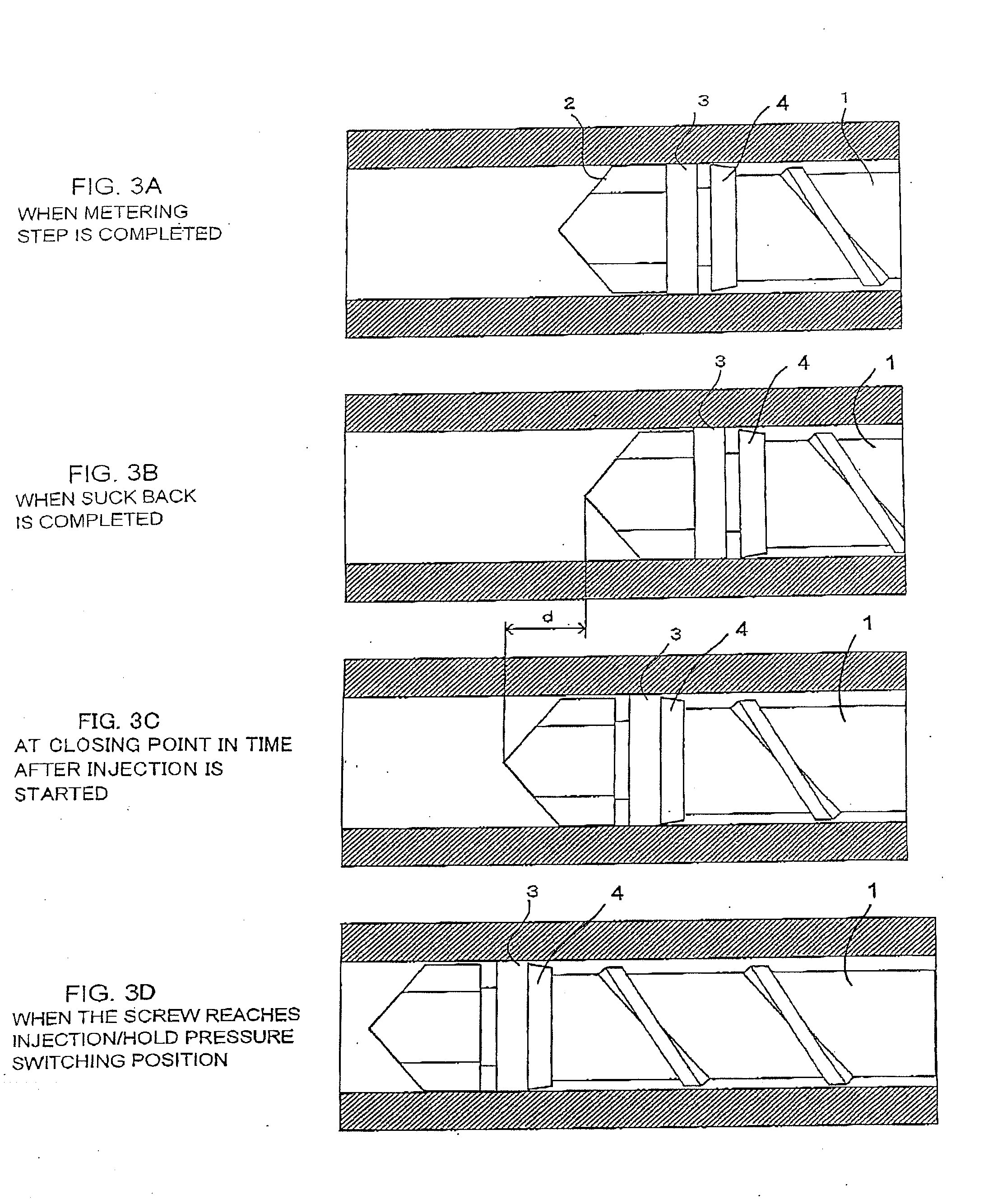

[0083]processing of the continuously molding cycle using the injection molding machine of the invention will be explained using a flowchart shown in FIG. 8.

[0084]FIG. 8 is a flowchart showing an algorithm of processing for detecting a peak value of a screw rotational force when the screw moves forward in the injection / hold pressure step shown in FIG. 3A to FIG. 3D, for determining whether a molded article is non-defective or defective depending upon the detected peak value of the rotational force, screw position or time, and for correcting the molding condition such as the injection / hold pressure switching position and the injection speed switching position. In this embodiment, this processing is executed by the PMC CPU 21. In this embodiment, a correction amount of the injection / hold pressure switching position is obtained based on the screw position where the peak value of the rotational force is detected, and this injection / hold pressure switching position is changed.

[0085]Relati...

second embodiment

[0148]In the processing of the continuously molding cycle explained using the flowchart in FIG. 10 in the pre-injection screw movement step, the peak value of the rotational force applied to the screw due to a reversely flowing resin is detected in the injection / hold pressure step, and a physical amount 1 at that time is obtained. Further, a peak value of the rotational force applied to the screw due to a reversely flowing resin is detected, and a physical amount 2 at that time is obtained. Then, based on the obtained physical amount 1 and physical amount 2, the VP switching position is corrected and non-defective / defective determination of the molded article is made. However, a peak value of a screw rotational force and a physical amount may be detected in the pre-injection screw movement step without carrying out detection of a rotational force peak value and a physical amount in an injection / hold pressure step, and the VP switching position may be corrected and the non-defective / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com