Spray type heat exchange device

a heat exchange device and spray type technology, applied in indirect heat exchangers, milk preservation, lighting and heating apparatus, etc., can solve the problems of large amount of liquid refrigerant required, difficult to enter liquid refrigerant into the inlet of the compressor, increased power consumption of the compressor, etc., to maximize space utilization, maximize the number of heat exchange tubes, and maximize the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

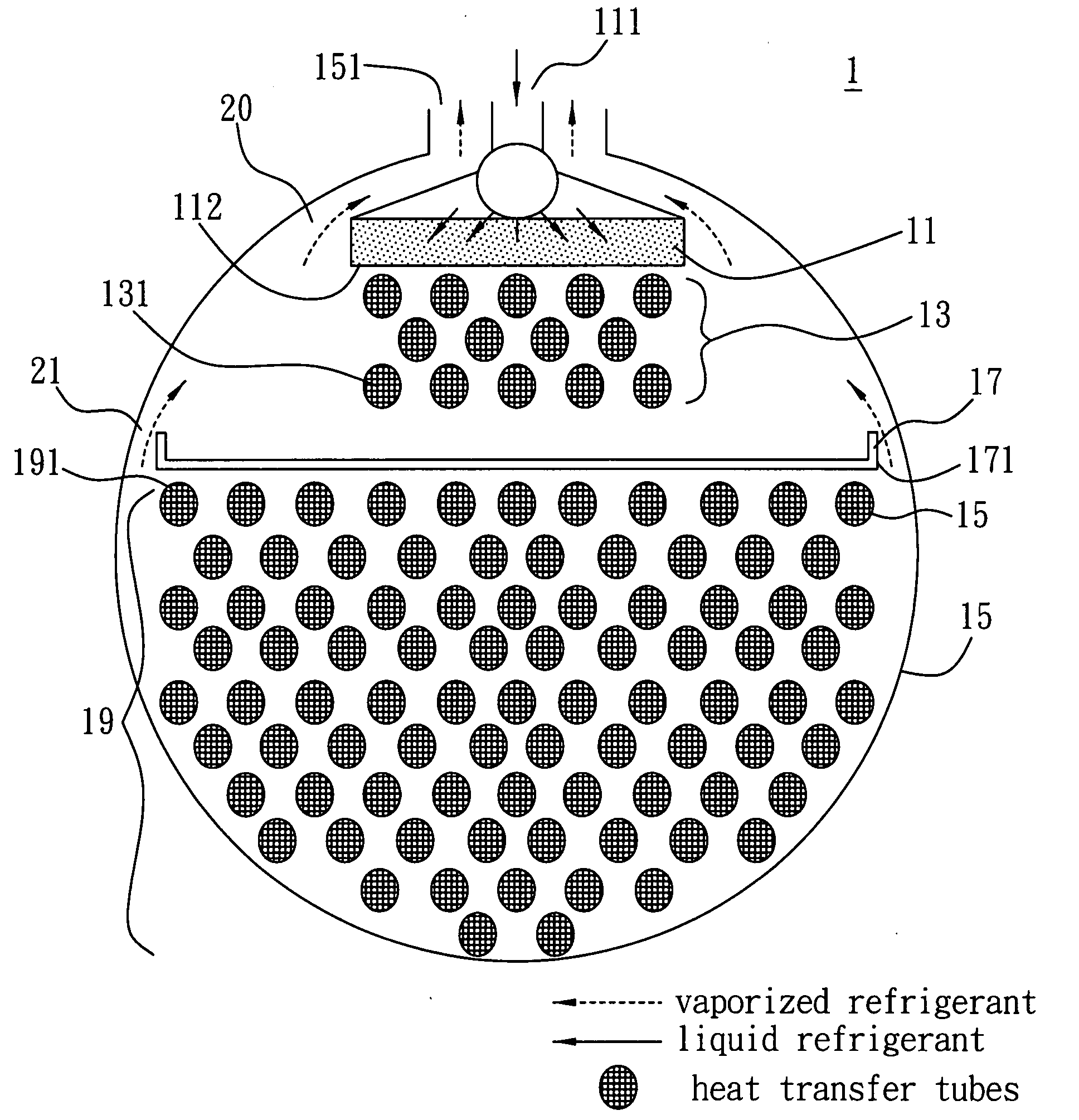

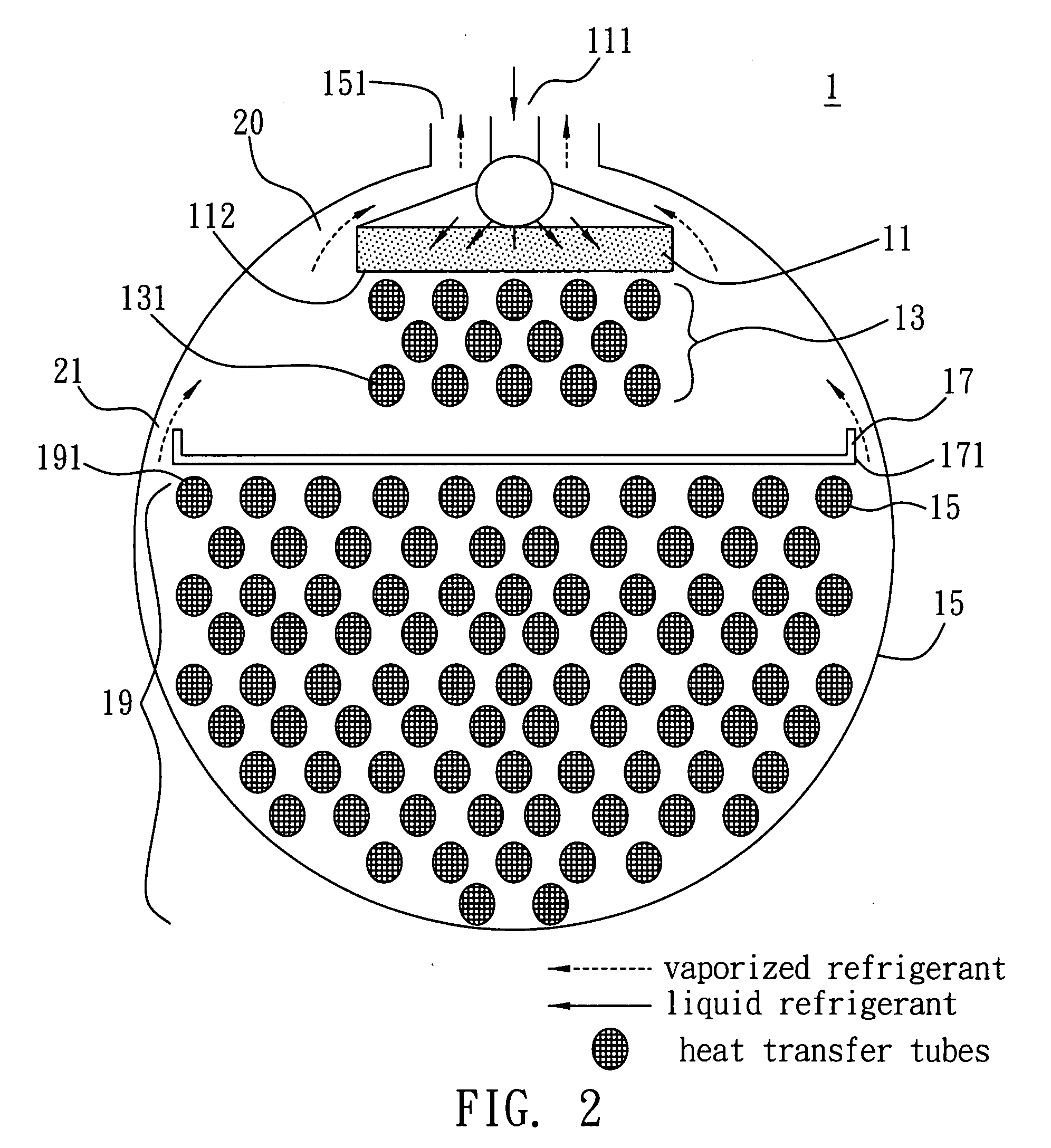

[0031]FIG. 2 is a sectional diagram of a spray type heat exchange device 1 the present invention. As shown in FIG. 2, the spray type heat exchange device 1 has a shell 15. Inside the shell 15 there are disposed sequentially, a spray unit 11, a first group set of heat transfer tubes 13, a distributing unit 17, and a second group set of heat transfer tubes 19.

[0032]The spray unit 11 has an inlet 111 connected with a refrigerant supply source (not shown), and a spray surface 112 having a plurality of dripping holes or dripping slots (not shown) disposed thereon for allowing the refrigerant to drip downward. There are no special limits on size, shape and distribution of the dripping holes or dripping slots, as long as liquid refrigerant can be uniformly dripped through the whole spray surface 112 in coordinate with supply of the refrigerant. The dripping holes or slots are preferably located at a position corresponding to the heat transfer tubes such that refrigerant dripped from the d...

second embodiment

[0042]FIG. 3 is a sectional diagram of a spray type heat exchange device according to the present invention. As shown in FIG. 3, besides a spray unit 11, a first group set of heat transfer tubes 13, two distributing units 17-1, 17-2, and a second group set of heat transfer tubes 19 that are disposed sequentially in shell 15 of a spray type heat exchange device 2, the spray type heat exchange device 2 has another distributing unit 23 and a third group set of heat transfer tubes 25 disposed below the second group set of heat transfer tubes 19.

[0043]The distributing unit 23 has a nearly opened rectangular section and in the shape of a shallow plate. The distributing unit 23 also has a plurality of dripping holes and / or dripping slots disposed on a whole surface 231 thereof. Similarly, there are no special limits on size, shape and distribution of the dripping holes or slots, as long as the liquid refrigerant can uniformly drip through the surface 231 in combination with supply of refri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com