Heat-dissipation device having dust-disposal mechanism

a technology of heat dissipation device and dust dissipation mechanism, which is applied in the direction of cleaning heat dissipation device, non-rotary device cleaning, lighting and heating apparatus, etc., can solve the problems of significantly reducing the heat dissipation capability of the heat dissipation device, and the accumulation of dust in the air between the metallic fins of the cooling fin, so as to quickly remove waste heat and improve the heat dissipation capability of the heat dis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

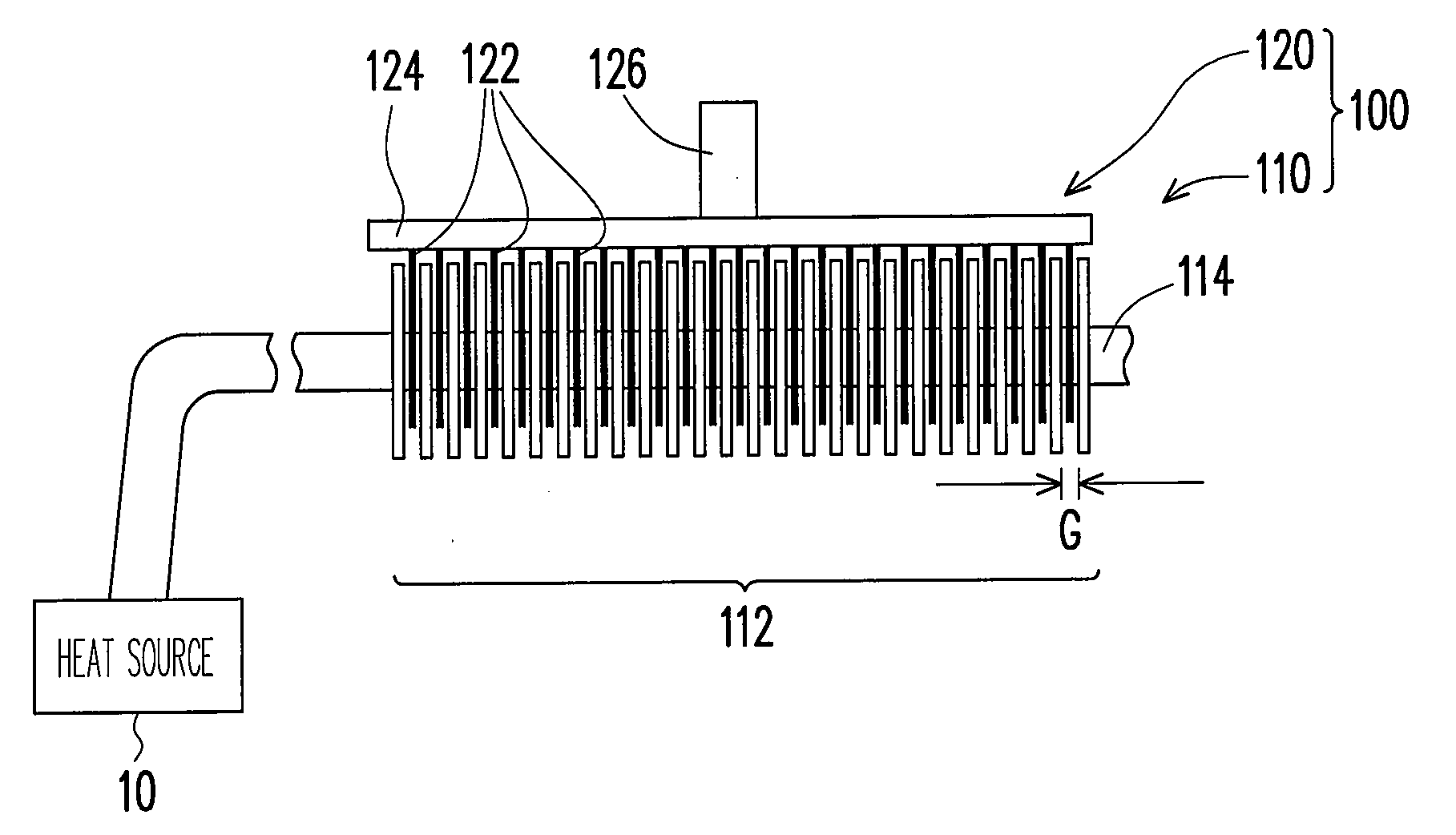

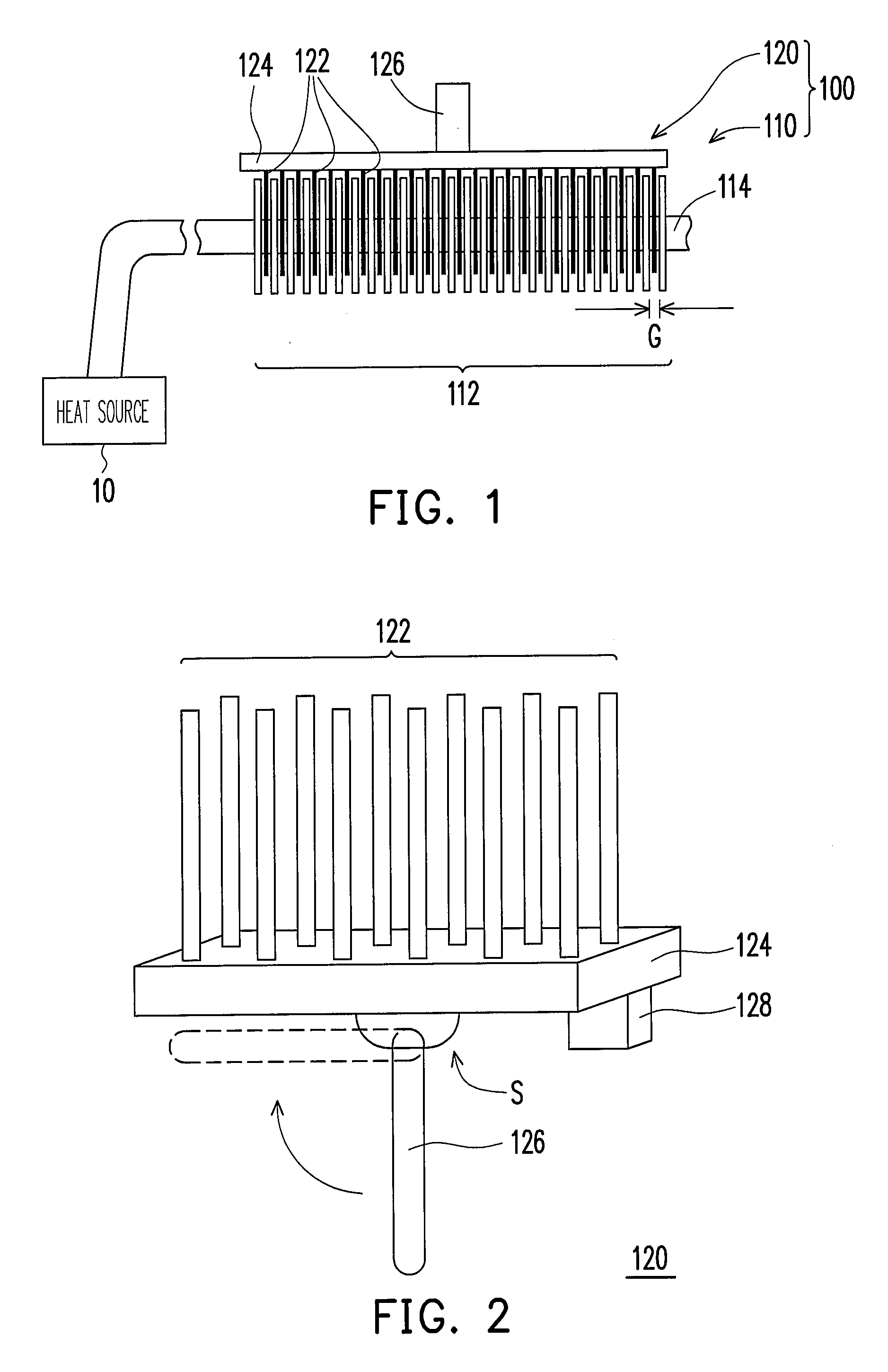

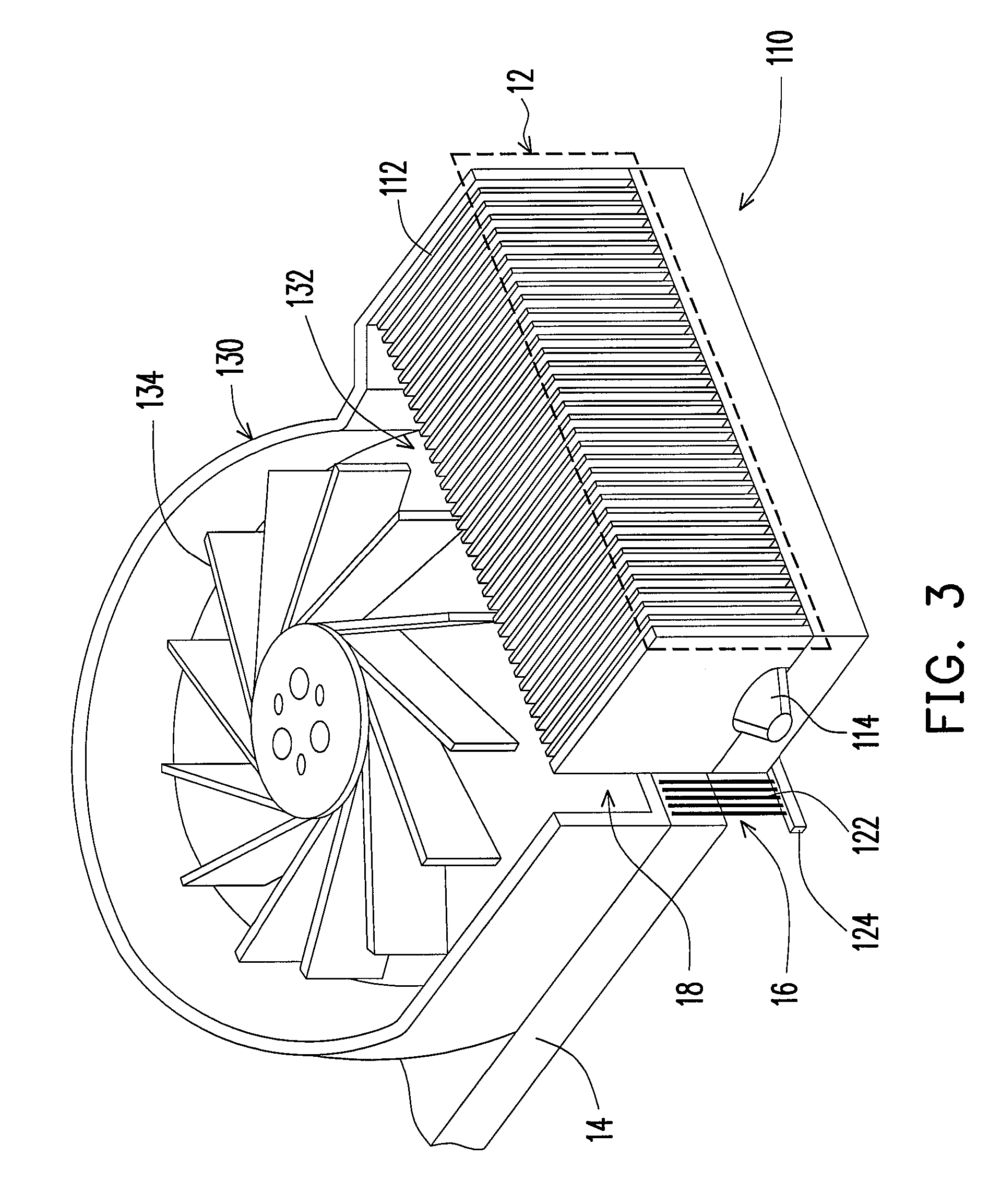

[0023]FIG. 1 is a schematic view of a heat-dissipation device having a dust-disposal mechanism according to an embodiment of the present invention. Referring to FIG. 1, the heat-dissipation device 100 mainly includes a heat-conducting module 110 and a dust-disposal mechanism 120, and the heat-conducting module 110 is used to dissipate heat for electronic devices with high heat-generating rate, so as to reduce the working temperature of the electronic devices in a system. The heat-conducting module 110 is generally made of metallic material with high heat conductivity such as Cu and Al, and is disposed on the electronic devices and connected to an air-cooling heat-dissipation module or a water-cooling heat-dissipation module in the system, so as to achieve the purpose of heat-dissipation.

[0024]In this embodiment, the heat-conducting module 110 includes a plurality of metallic fins 112 arranged in parallel, and the metallic fins 112 arranged in parallel are stacked with a gap G formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com