[0008]In order to overcome the problems described above, preferred embodiments of the present invention provide a paper feeder, which makes it possible for a paper feed cassette not only to be pushed into and drawn out from a paper storage unit smoothly, but also makes it possible for the paper feed cassette to be maintained in a stable condition when stored in the cassette storage unit; and an image forming device including the same paper feeder.

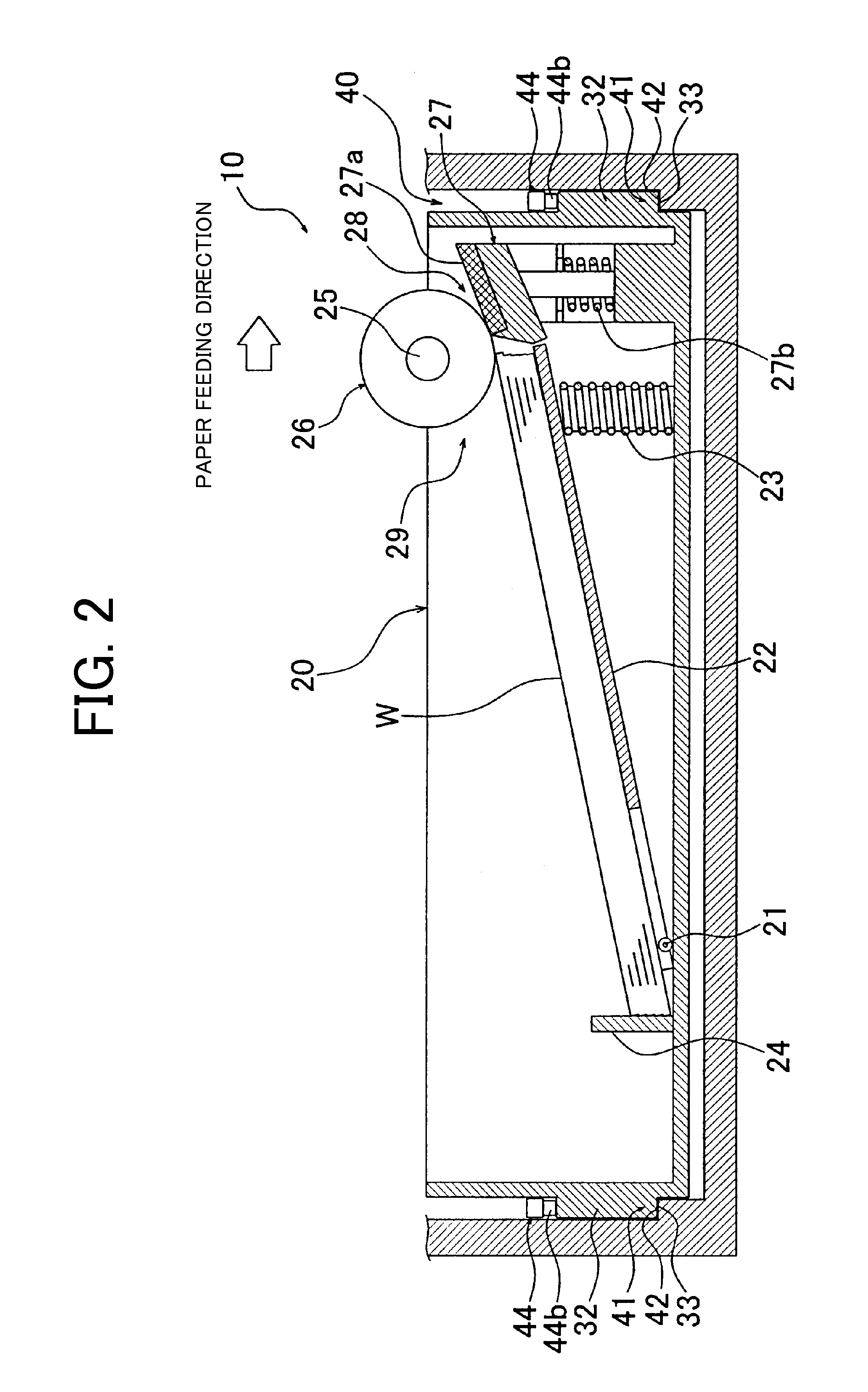

[0015]According to the above-described preferred embodiments of the present invention, the paper feeder is preferably configured such that when the paper feed cassette is moved along the storing direction thereof inside the cassette storage unit, the guide portion placed on the rotating member is slidably moved by the rotation of the rotating member. In the above-described paper feeder, the cassette storage unit includes the placement portion on which the guide portion is placed at the storage position where the paper feed cassette is stored in the cassette storage unit. Therefore, the paper feed cassette can be pushed in and drawn out smoothly by being slidably moved inside the cassette storage unit, and since the guide portion is placed on the placement portion, the paper feed cassette stored at the storage position can be maintained in the stable condition. Accordingly, oscillation of the paper feed cassette generated when the paper is transported inside the paper feed cassette can be effectively reduced.

[0016]According to the above-described preferred embodiments of the present invention, since the paper feeder is configured such that the guide portion is placed on the placement portion by surface contact, the paper feed cassette stored at the storage position can be maintained in a more stable condition, and the oscillation of the paper feed cassette can be reduced more effectively. Moreover, since the longitudinal size in the storing direction of the portion on which the guide portion is placed by surface contact is greater than the maximum width size in the storing direction of the paper accommodated inside the paper feed cassette, the oscillation can be prevented from being transmitted from the paper feed cassette to a

full width of the transported paper, and the paper can be accurately transported.

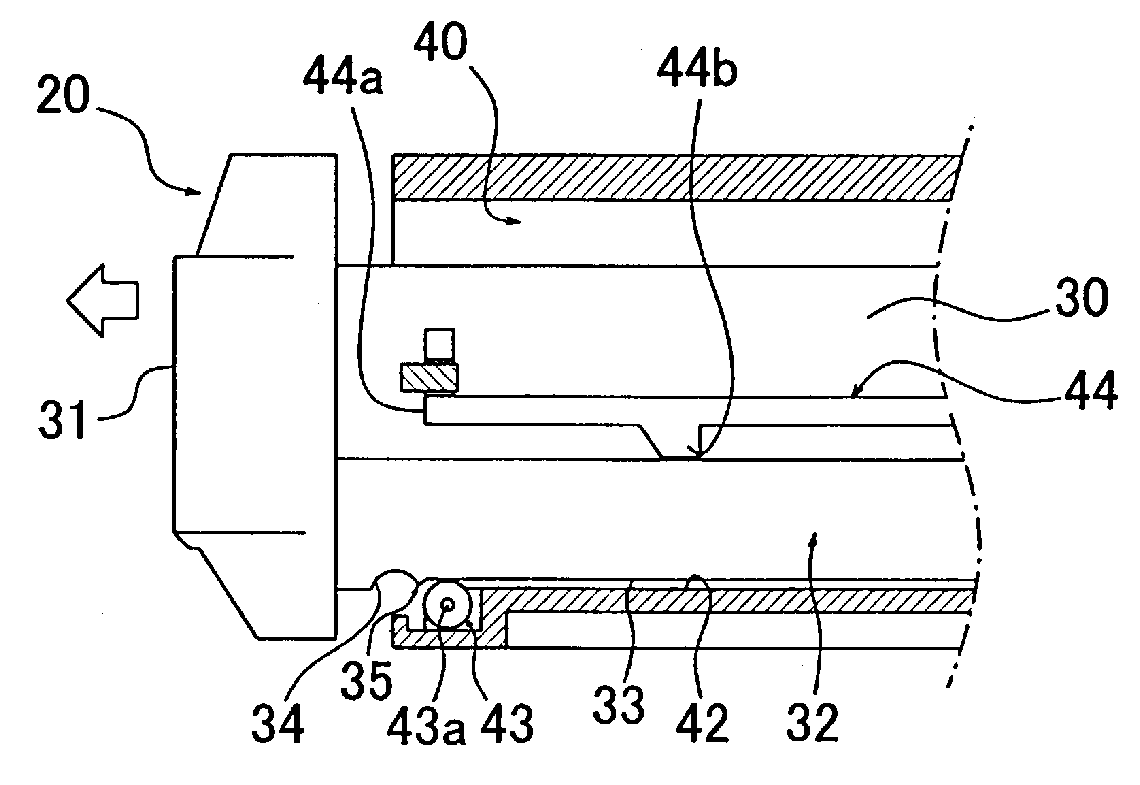

[0017]According to the above-described preferred embodiments of the present invention, the paper feeder is configured such that the rotating member protrudes above the placement portion towards the guide portion side of the paper feed cassette and such that the paper feed cassette includes the rotating-member engaging portion to be engaged with the rotating member at the storage position. Therefore, when the paper feed cassette is moved inside the cassette storage unit, the guide portion is placed on the rotating member, and when the paper feed cassette is stored at the storage position, the guide portion is placed on the placement portion. Accordingly, with this simple configuration, the paper feed cassette can be slidably moved smoothly and also can be maintained stably at the storage position.

[0018]According to the above-described preferred embodiments of the present invention, in the paper feeder, since the rotating member is arranged on the rear side of the placement portion in the storing direction of the cassette storage unit, when pushing in and drawing out the paper feed cassette, the guide portion can be smoothly moved by the rotating member.

[0019]According to the above-described preferred embodiments of the present invention, the paper feeder includes the step portion arranged between the rotating-member engaging portion and the guide portion of the paper feed cassette such that the rotating member passes over the step portion when the paper feed cassette moves from the storage position. Accordingly, with this simple configuration, resistance can be applied to a force which moves the paper feed cassette when the paper feed cassette is pushed in and drawn out. Moreover, a possibility that the paper feed cassette stored at the storage position moves improperly can be reduced.

Login to View More

Login to View More  Login to View More

Login to View More