Exhaust pipe structure improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

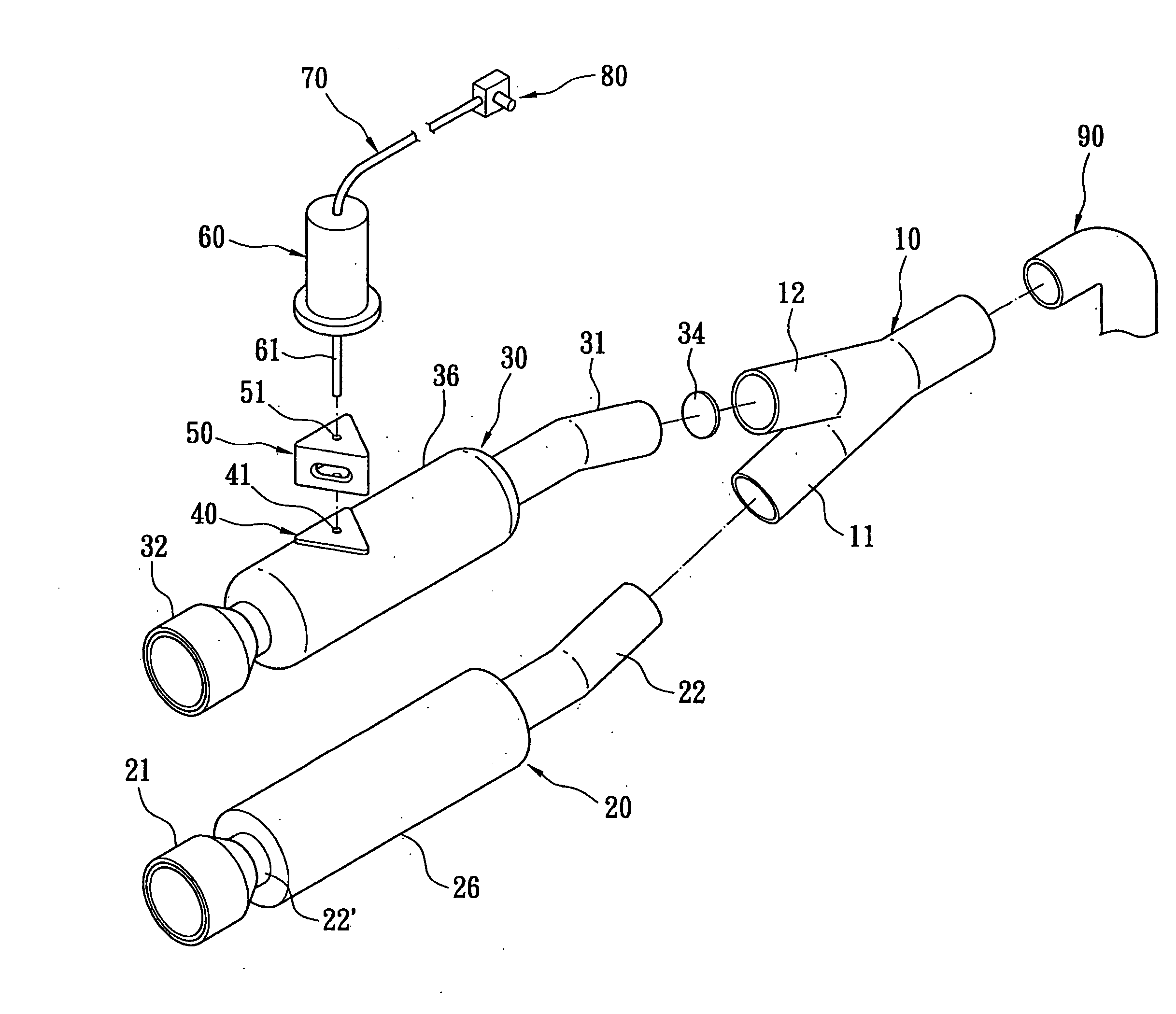

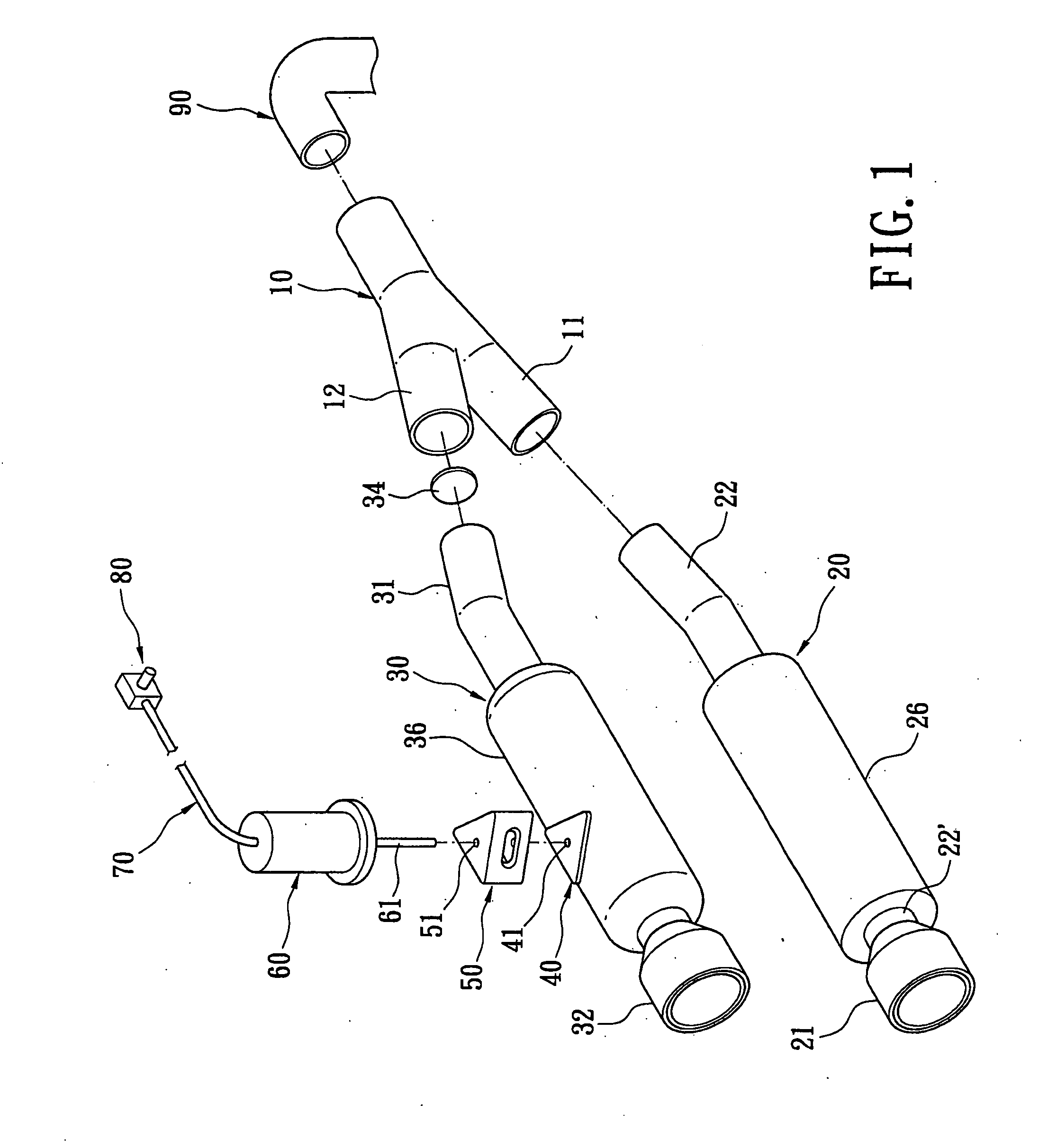

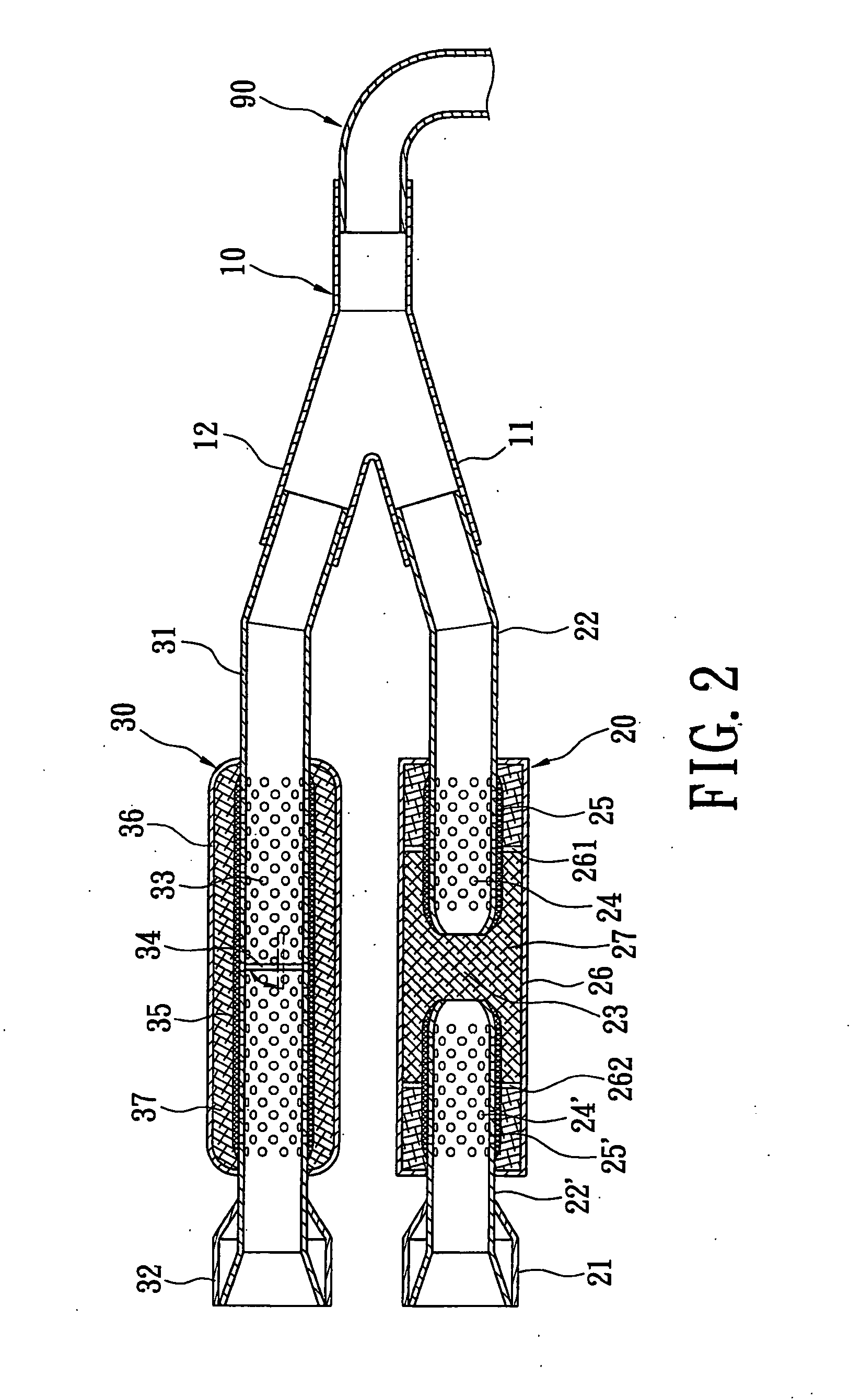

[0016]References are made to FIG. 1 and FIG. 2. An exhaust pipe structure improvement of the present invention is connected with a joint pipe 90 of an engine of a car, and comprises a bifurcation pipe 10, a first muffling pipe 20, a second muffling pipe 30, a placed base 40, a heat-insulating block 50 and a control device 60.

[0017]The bifurcation pipe 10 is a hollow pipe. One end of the bifurcation pipe 10 is divided into a first branch pipe 11 and a second branch pipe 12 and the other end is connected with the joint pipe 90 of the engine.

[0018]One end of the first muffling pipe 20 is connected with the first branch pipe 11 of the bifurcation pipe 10, and the other end thereof is sleeved by a tail pipe 21. The first muffling pipe 20 has two hollow pipe housings 22, and 22′, the two pipe housings 22, and 22′ are spaced at intervals and a flow region 23 is formed between the two pipe housings 22, and 22′. The two pipe housings 22, and 22′ have a plurality of muffling holes 24, and 24′...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com