Oxidation apparatus and method for semiconductor process

a technology of oxidation apparatus and semiconductor process, which is applied in the direction of solid-state diffusion coating, chemical vapor deposition coating, coating, etc., can solve the problems of poor planar uniformity of film thickness, high oxidation rate, and insufficient use of conventional oxidation methods, so as to simplify and speed up the adjustment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In the process of developing the present invention, the inventors studied problems of conventional techniques for semiconductor processes, in relation to a method for forming an oxide film by oxidation. As a result, the inventors have arrived at the findings given below.

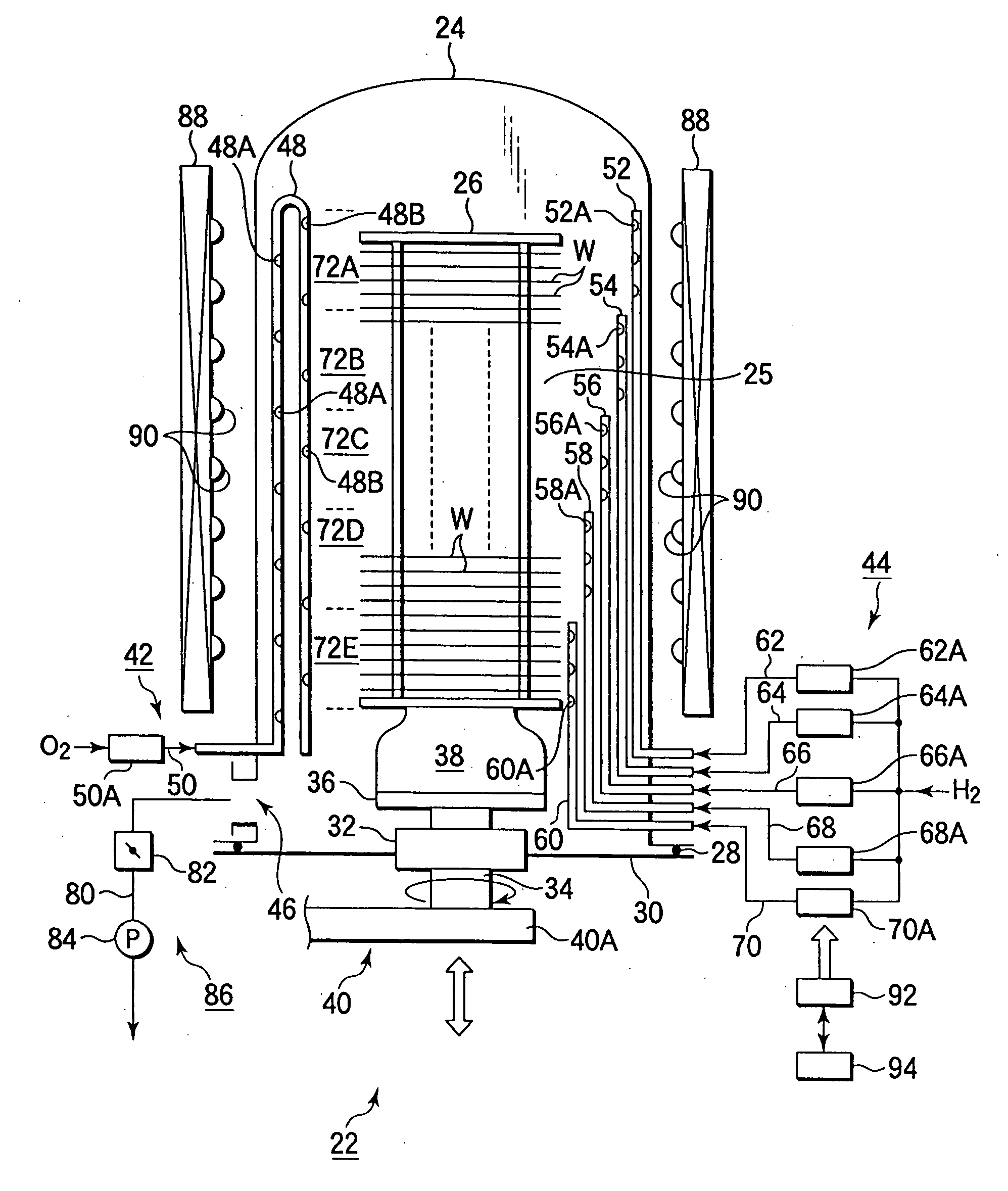

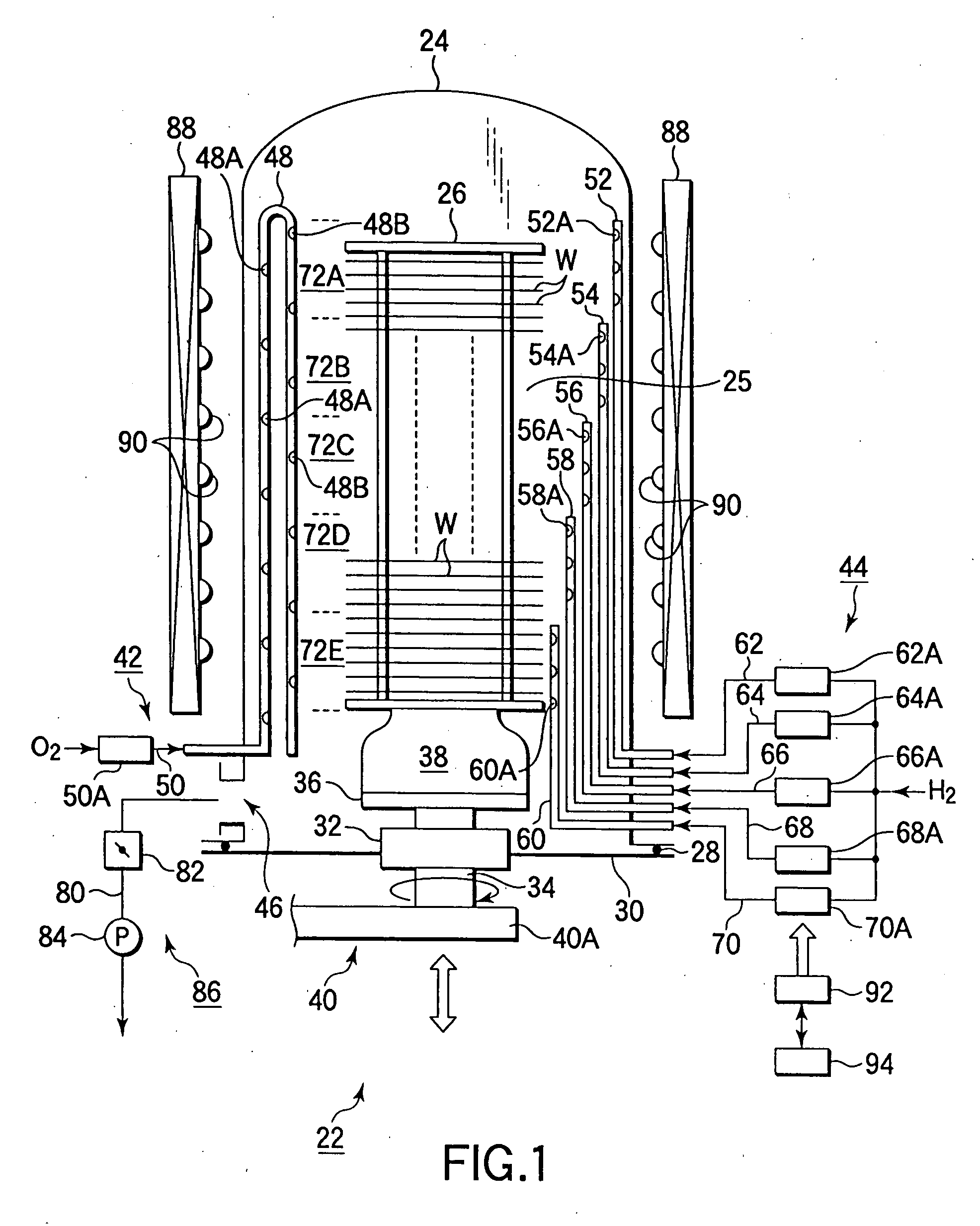

[0028]FIG. 9 is a view schematically showing a conventional vertical heat processing apparatus (oxidation apparatus). The oxidation apparatus includes a process container 2 formed of a quartz cylinder with a ceiling, in which a wafer boat 4 made of quartz is accommodated. The wafer boat 4 can support a plurality of, such as about 25 to 150, semiconductor wafers W at predetermined intervals in the vertical direction. The wafer boat 4 is supported on a heat-insulating cylinder 6, and is moved up and down by a boat elevator (not shown), so that the wafer boat 4 is loaded and unloaded into and from the process container 2 from and to a lower side. The bottom port of the process container 2 is airtightly closed by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com